Ultra-Thermal Process Tubing | ASTM A312 316L/2205 Seamless Coils | 1200°C Oxidation Resistance | JIT Delivery with ±0.05% Tolerance Control

Ultra-Thermal Process Tubing | ASTM A312 316L/2205 Seamless Coils | 1200°C Oxidation Resistance | JIT Delivery with ±0.05% Tolerance Control

Contact form

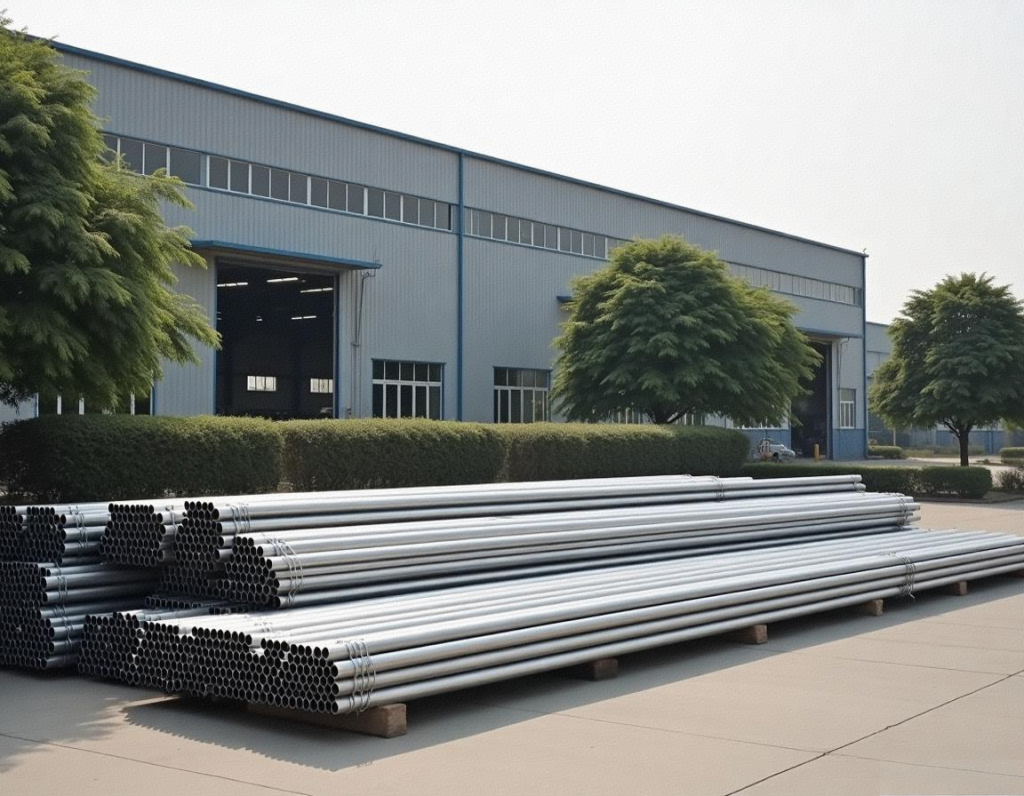

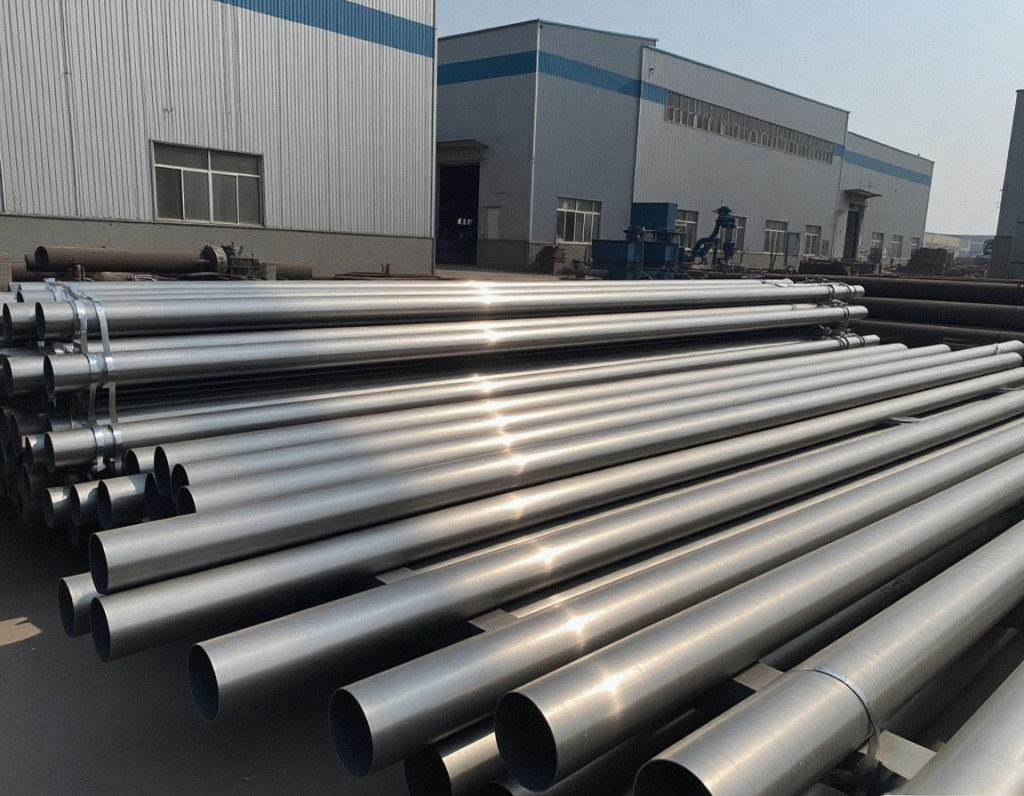

High-Temperature Industrial Exhaust Solutions

Engineered for extreme thermal demands, our 8 inch stainless steel stove pipe single wall withstands 900°C continuous operation with 316Ti alloys, while double wall stainless steel chimney pipe systems reduce external surface temps by 60% through air-gap insulation. The double wall stainless steel stove pipe variant combines ASTM-certified 304L interiors with 430-grade outer sleeves for cost-effective durability.

Precision Fabrication & Safety Compliance

Optimize combustion systems with:

- Robotic welding on double wall stainless steel stove pipe joints (AWS D1.6 certified)

- CNC flanging for seamless 8 inch stove pipe installations

- Press brake forming of double wall chimney pipe brackets (3mm tolerance control)

| Specification | Detail |

|---|---|

| Max Continuous Temp | 900°C (Single Wall) |

| Insulation Gap | 25mm (Double Wall Systems) |

| Pressure Rating | -10kPa to +2kPa (Chimney) |

| Surface Finish | 120 Grit Brushed |

| Compliance | ASTM A53 + UL 103HT |

Certified Combustion Infrastructure

Deploy bold 8 inch stainless steel stove pipe in biomass boilers or double wall chimney pipe in commercial kitchens. Our inventory includes 310S alloy pipes for pyrolysis reactors and 441-grade variants for coastal environments. All double wall stainless steel stove pipe orders ship in seaworthy crates within 7 days, with MOQ flexibility and phased TT payment terms for HVAC contractors.