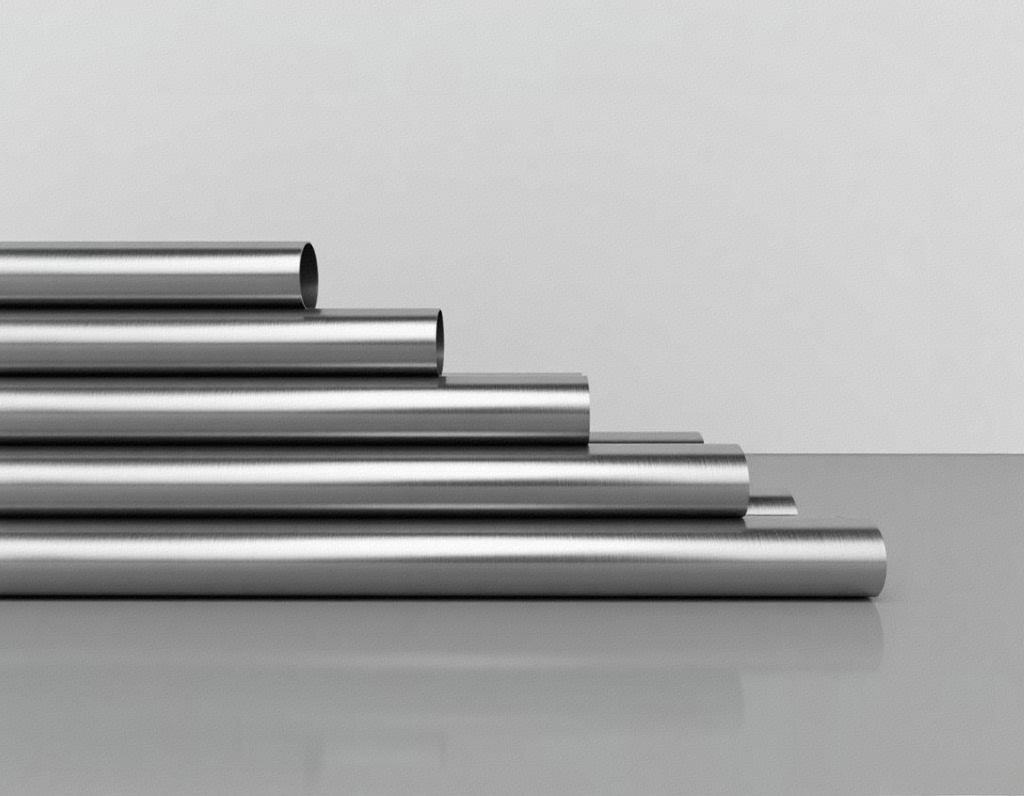

Austenitic Chromium-Nickel Ducting | Burst-Resistant Seamless Lines | Factory-Direct Polished Conduits Immediate Dispatch

Austenitic Chromium-Nickel Ducting | Burst-Resistant Seamless Lines | Factory-Direct Polished Conduits Immediate Dispatch

Contact form

Precision-Engineered Flow Solutions for Demanding Systems

Crafted to ASTM standards with ±0.1%-0.3% tolerance, these stainless steel Y pipes ensure flawless fluid diversion in high-pressure environments. The 2B finish combined with 120-mesh polishing minimizes particulate adhesion, ideal for pharmaceutical or food-grade applications requiring ultra-smooth surfaces.

| Specification | Detail |

|---|---|

| Diameter Range | 1mm – 100mm |

| Material Composition | 304/304L/316L/321/2205 |

| Surface Treatment | 120 Mesh Electrolytic Polishing |

| Pressure Rating | 150 PSI – 2000 PSI |

| Customization Options | Threading, Decoiling, Precision Cut |

High-Performance Connectivity for Industrial Networks

Threaded stainless steel pipes with triple-verified concentricity enable leak-proof jointing in chemical processing lines. Reinforced seams withstand thermal cycling from -30°C to 800°C, while the seaworthy wooden packaging (60x40x40cm crates) guarantees dent-free global transit.

Advanced Exhaust Management Solutions

Engineered for extreme environments, triple wall stainless steel chimney pipes feature interlocked austenitic layers resistant to acidic condensation. Rapid 7-day dispatch ensures timely integration into HVAC upgrades or industrial boiler retrofits, backed by 30% advance payment terms and 1-ton MOQ flexibility.