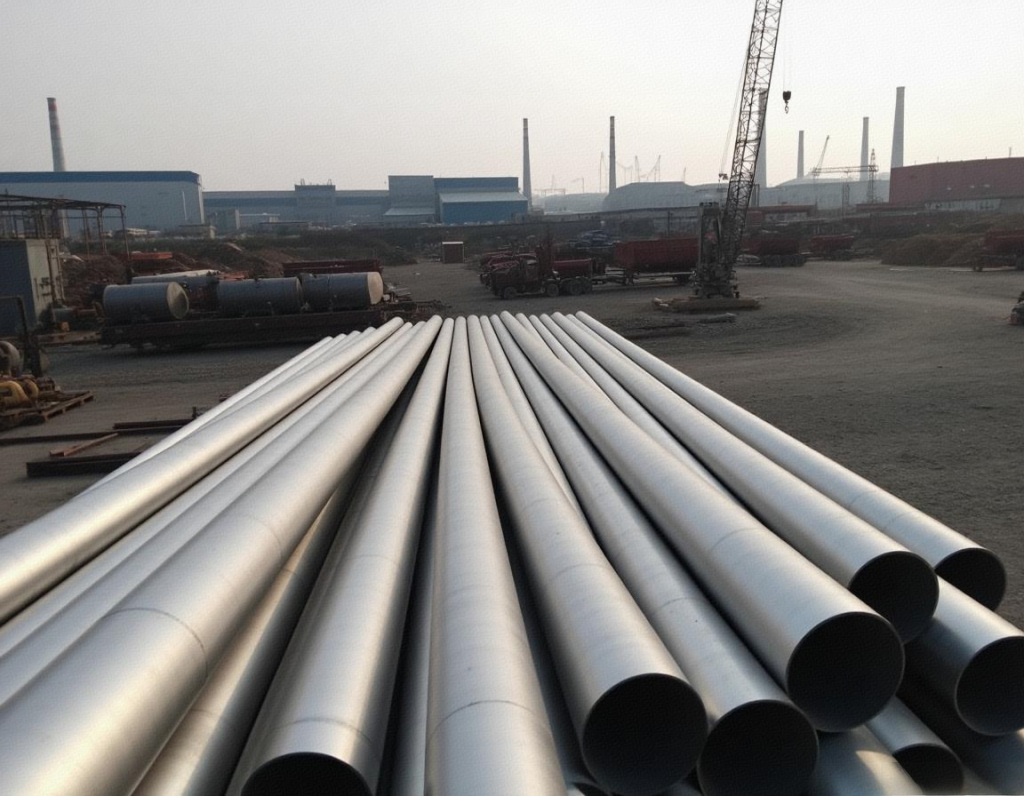

Stocked Ready-to-Ship! Customizable ASTM A312/A213/A269 Seamless Tubing - 304/316L/Duplex 2205 Steel with Laser-Cut Precision

Stocked Ready-to-Ship! Customizable ASTM A312/A213/A269 Seamless Tubing - 304/316L/Duplex 2205 Steel with Laser-Cut Precision

Contact form

Precision-Engineered Stainless Steel Tubing Solutions

Manufactured to ASTM standards, our stainless steel tubes feature ±0.1%–0.3% dimensional accuracy and strong corrosion resistance, ideal for construction, chemical industry, and medical equipment applications. Available in diameters from 1mm to 100mm, these 304/304L/316L/321/310S/2205 alloy tubes undergo bending, welding, and cutting processing for custom workflows.

| Schedule | Wall Thickness (mm) | Pressure Rating (psi) | Application |

|---|---|---|---|

| **Schedule 10** | 2.11 | 1,200 | Low-pressure systems |

| **Schedule 40** | 3.68 | 2,500 | High-pressure pipelines |

| **Single Wall Stove Pipe** | 1.24 | 800 | Ventilation systems |

| Schedule 5 | 1.65 | 950 | Light industrial |

| Schedule 80 | 5.56 | 3,800 | Extreme conditions |

Optimized Performance Specifications

The schedule 10 stainless steel pipe chart details wall thickness variations for thermal stability, while schedule 40 stainless steel pipe pressure ratings ensure compliance with industrial safety thresholds. For ventilation, single wall stainless steel stove pipe configurations provide heat-resistant durability under 800 psi.

Logistics & Customization

Tubes ship within 7 days via standard seaworthy wooden packaging (60x40x40 cm crates). Minimum orders start at 1 ton, with flexible payment terms (30% advance + 70% balance). Surface finishes include 120 mesh polishing and 2B cold-rolled options for enhanced aesthetics and functionality.