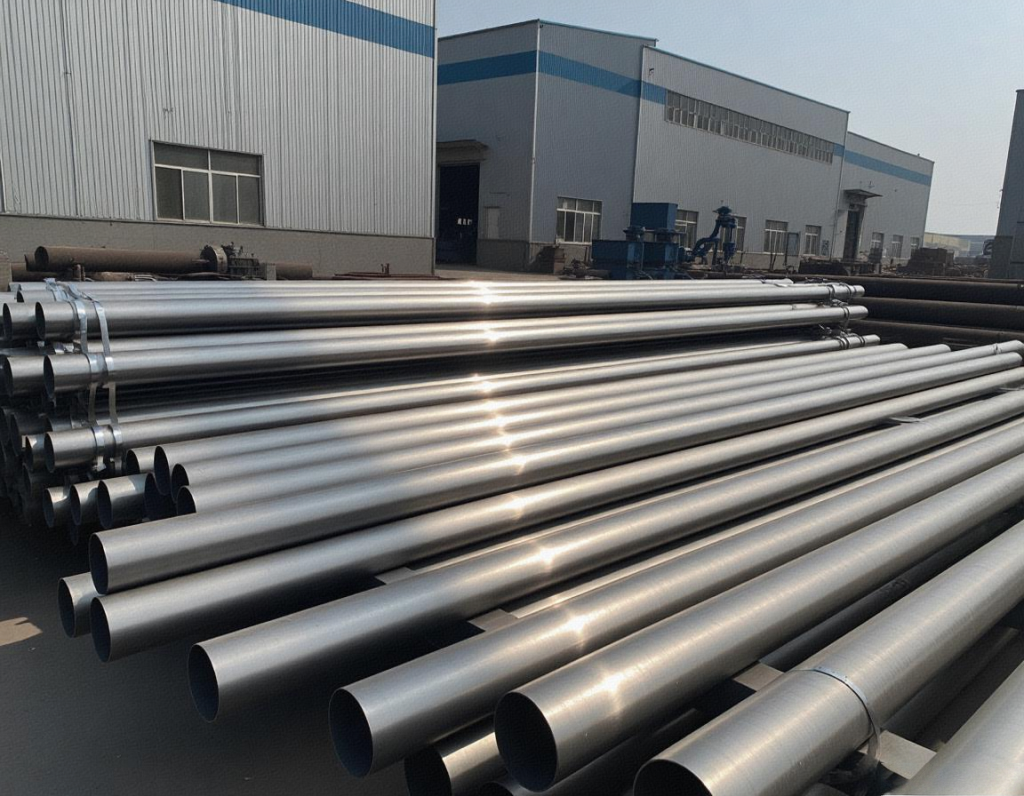

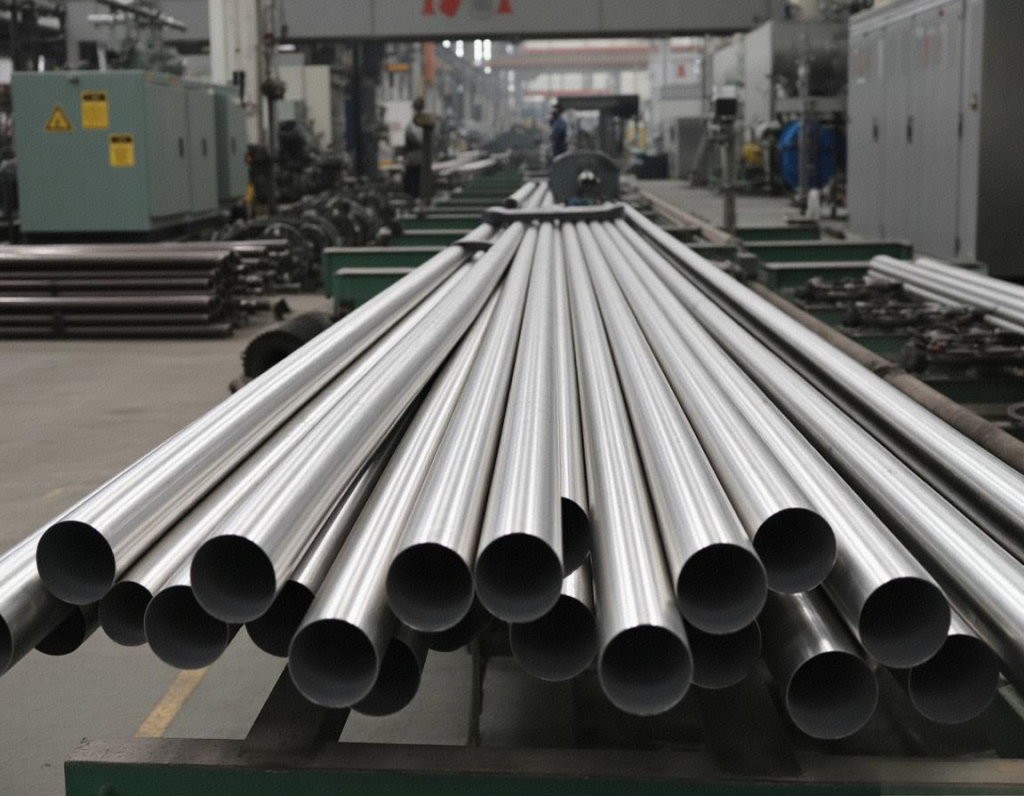

Precision-Engineered Austenitic Steel Welded Pipes | Industrial-Grade 304/316L/2205 Alloys | Tailor-Cut Dimensions & Anti-Corrosion Properties

Precision-Engineered Austenitic Steel Welded Pipes | Industrial-Grade 304/316L/2205 Alloys | Tailor-Cut Dimensions & Anti-Corrosion Properties

Contact form

High-Performance Austenitic Steel Conduits

Engineered for precision across industrial applications, our 2.5 inch stainless steel exhaust pipe kit combines rigorous ASTM standards with advanced fabrication. Available in diameters spanning 2in stainless steel exhaust pipe to 3 8 stainless steel pipe, these tubes feature ±0.1%-0.3% dimensional accuracy and 2B surface finishes. Ideal for chemical processing or medical infrastructure, the material portfolio includes 301L, 316Ti, and 2205 alloys, optimized for stress corrosion cracking resistance.

Custom-Engineered Fluid Transport Solutions

Seamlessly integrate bold stainless steel tubing into complex systems with on-demand processing:

- Bending for tight-radius exhaust layouts

- Decoiling to minimize material stress

- Plasma cutting for surgical precision

| Specification | Detail |

|---|---|

| Wall Thickness Range | 0.5mm - 12mm |

| Surface Roughness | 120 Mesh Finish |

| Pressure Rating | 1500 PSI (316L Grade) |

| Temperature Tolerance | -50°C to 800°C |

| Certifications | ASTM A269/A312 Compliant |

Multi-Industry Fluid Dynamics Mastery

From bold 3 8 stainless steel pipe networks in HVAC systems to heavy-duty 2.5 inch exhaust manifolds, our inventory supports rapid deployment with 7-day lead times. The 304N and 310S variants deliver enhanced creep resistance for high-temperature environments, while 410L alloys provide cost-effective durability for structural frameworks. Each unit ships in seaworthy crates with dual-stage payment flexibility, ensuring frictionless global procurement.