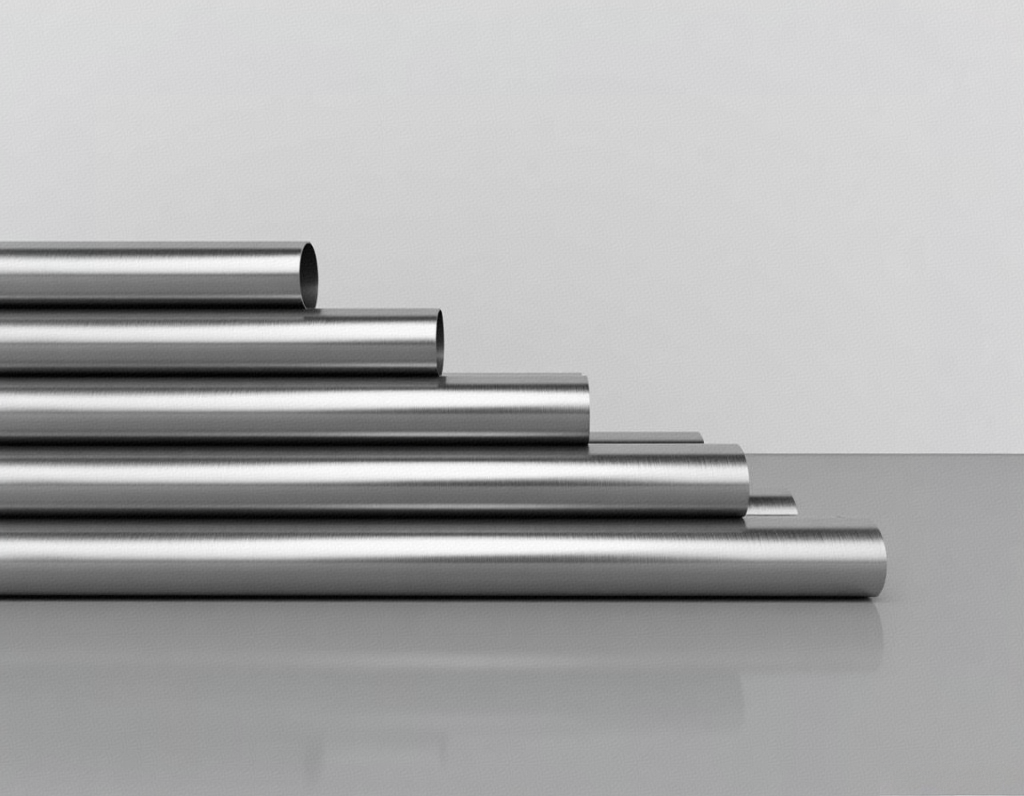

Precision-Engineered Metallic Channels | Abrasion-Immune Seamless Rings | Zero-Defect Surface Stock Ready-Ship

Precision-Engineered Metallic Channels | Abrasion-Immune Seamless Rings | Zero-Defect Surface Stock Ready-Ship

Contact form

Precision-Engineered Flow Solutions for Extreme Environments

Manufactured to ASTM standards with ±0.1%-0.3% tolerance, these seamless conduits combine ferritic chromium-molybdenum alloys with salt-spray certified surfaces. Ideal for offshore rigs or chemical processing plants, the 120-mesh electro-polished finish ensures zero particulate shedding in high-purity applications.

| Specification | Detail |

|---|---|

| Diameter Spectrum | 1mm – 100mm (incl. 3-inch custom profiles) |

| Material Grades | 304/316L/310S/2205/430 |

| Surface Hardness | HV 200-300 (2B finish enhanced) |

| Thermal Stability | -60°C to 1100°C cyclic endurance |

| Fabrication Techniques | Hydroforming, CNC threading, beading |

High-Capacity Inventory for Critical Infrastructure

Laser-cut martensitic stainless steel transfer ducts withstand abrasive slurry flows in mining operations, while austenitic chromium-nickel elbow joints prevent stress corrosion cracking in nuclear cooling systems. Bulk orders ship in ISO-certified wooden crates (60x40x40cm) with 48-hour dispatch guarantees.

Dynamic Applications Across Industries

From food-grade pneumatic conveying tubes to exhaust scrubber manifolds, our seamless inventory supports just-in-time procurement. MOQ flexibility (1-ton+) paired with 30% advance payment terms ensures cost-efficient scaling for mega-projects requiring cyclic heat-resistant assemblies.