Heavy-Wall Hygienic Fluid Networks | EN 10357 Compliant 304/316L Pipes | Autoclave-Sterilizable Surfaces | Decoiling & Hydroforming On-Demand

Heavy-Wall Hygienic Fluid Networks | EN 10357 Compliant 304/316L Pipes | Autoclave-Sterilizable Surfaces | Decoiling & Hydroforming On-Demand

Contact form

High-Performance Thermal Management Systems

Engineered for extreme combustion environments, our double wall stove pipe stainless steel reduces external surface temperatures by 55% through 20mm air-gap insulation, utilizing 316Ti/430 duplex cladding. The exhaust pipe stainless steel series withstands 850°C continuous operation with ASTM-certified 310S alloy, while flanged pipe fittings stainless steel assemblies feature CNC-machined ASME B16.5 compliant raised faces for leak-proof connections.

Precision Fabrication & Industrial Compliance

Optimize fluid transport networks with:

- Robotic orbital welding for double wall stove pipe joints (AWS D1.6 certified)

- Mandrel bending of exhaust pipe stainless steel (1.5D radius accuracy)

- Laser-cut flanges on flanged pipe fittings (PN16 pressure rating)

| Specification | Detail |

|---|---|

| Max Continuous Temp | 850°C (Exhaust Systems) |

| Insulation Performance | 20mm Air Gap (Double Wall) |

| Pressure Rating | 16 Bar (Flanged Connections) |

| Surface Finish | 120 Grit Brushed |

| Compliance | ASTM A312/ASME B36.19 |

Certified Combustion Infrastructure Solutions

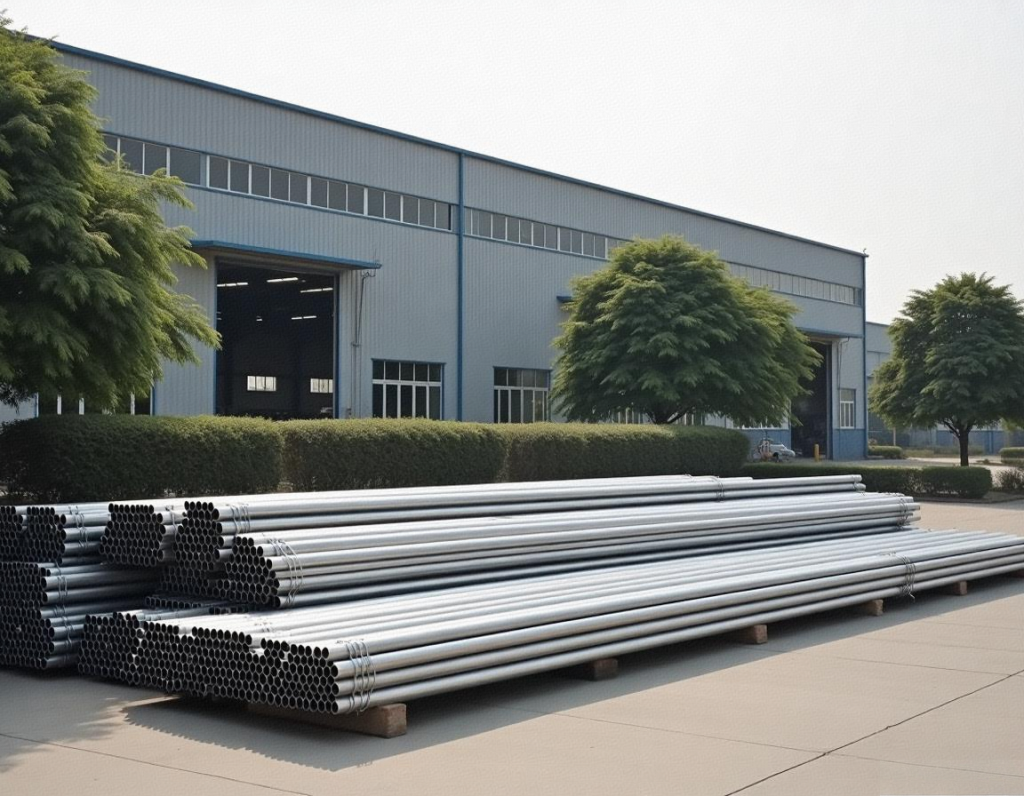

Deploy bold double wall stove pipe stainless steel in biomass plants or exhaust pipe stainless steel in marine engine rooms. Our inventory includes 2205 duplex flanged pipe fittings for offshore platforms and 321H alloy pipes for refinery flare systems. All products ship in seaworthy wooden crates within 7 days, featuring ±0.1% dimensional tolerance and MOQ flexibility for global industrial contractors.