Sanitary-Grade Austenitic Tubing | ASME-BPE Certified 304/316L/2205 Seamless Coils | High-Temperature Food Processing Pipes | Mill-Direct Bulk Stock + Laser Cutting

Sanitary-Grade Austenitic Tubing | ASME-BPE Certified 304/316L/2205 Seamless Coils | High-Temperature Food Processing Pipes | Mill-Direct Bulk Stock + Laser Cutting

Contact form

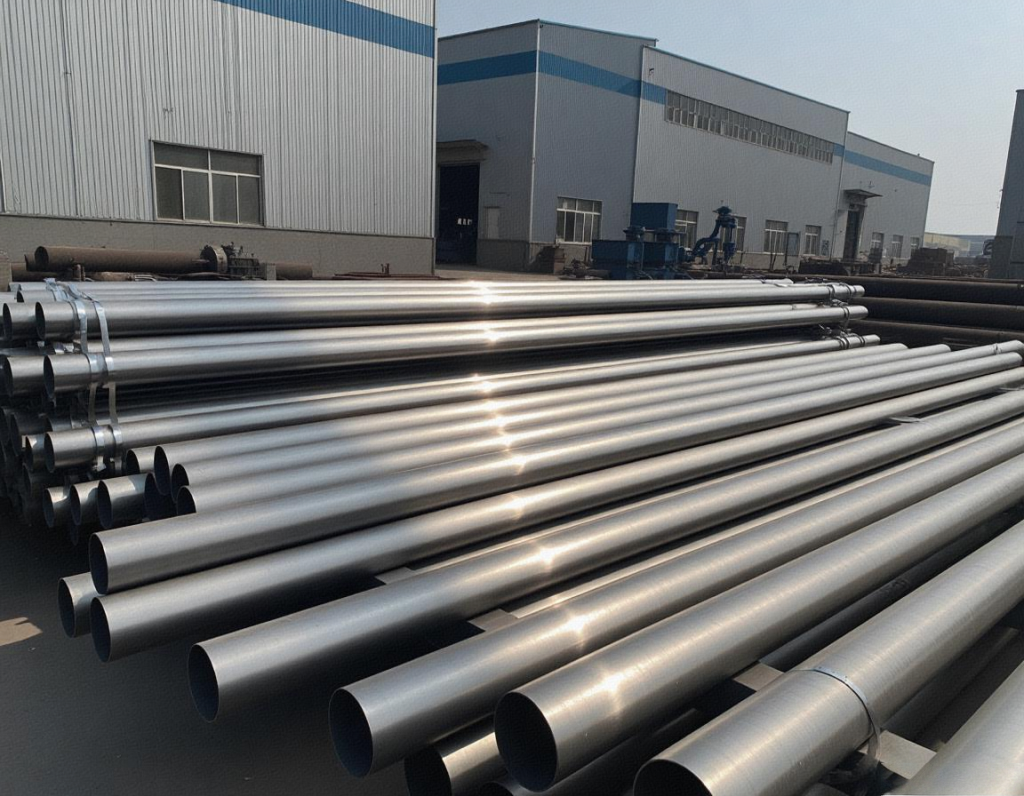

Precision-Fabricated Austenitic Conduit Systems

Engineered for extreme thermal cycling, our 6 stainless steel single wall stove pipe withstands 950°C continuous operation with ASTM-certified 304/316L alloys. The 5/8 stainless steel pipe series delivers ±0.1% dimensional accuracy for precision instrumentation, while 6 in stainless steel pipe configurations support industrial HVAC ducting with 2B polished surfaces and 120 mesh finishes.

Multi-Process Fabrication Capabilities

Optimize fluid transport networks through:

- Hydroforming for complex 6 in stainless steel pipe manifolds

- TIG welding on 5/8 stainless steel pipe assemblies (argon-shielded)

- Rotary draw bending of 6 stainless steel single wall stove pipe (1.5D radius)

| Specification | Detail |

|---|---|

| Pressure Resistance | 1,250 PSI (316L Grade) |

| Surface Roughness | Ra ≤ 0.8μm (2B Finish) |

| Thermal Cycling Capacity | 10,000 cycles @ 600°C ΔT |

| Diameter Range | 5/8" to 6" (16mm-152mm) |

| Compliance | ASTM A269/A312, ASME B36.19 |

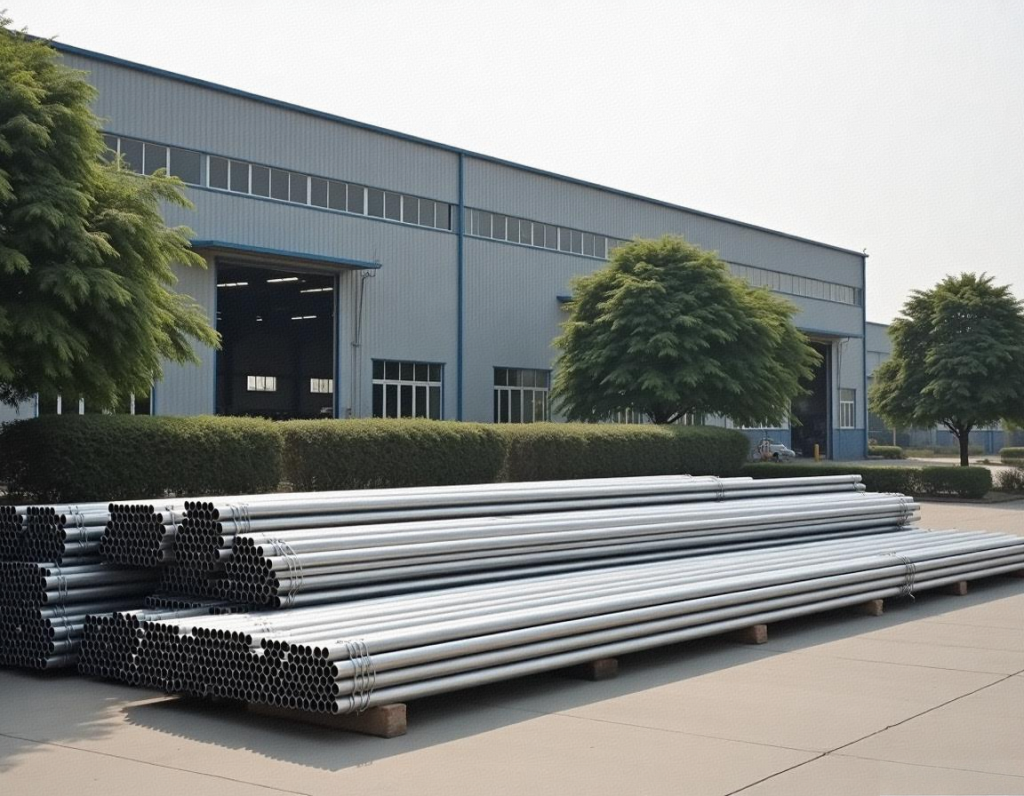

Cross-Industry Deployment Solutions

Deploy bold 6 stainless steel single wall stove pipe in biomass boilers or 5/8 stainless steel pipe in chemical injection systems. Inventory includes 2205 duplex steel for offshore applications and 310S alloys for pyrolysis reactors. All 6 in stainless steel pipe orders ship in seaworthy wooden crates within 7 days, with MOQ flexibility and phased payment terms for industrial contractors.