Precision-Etched Pharmaceutical Conduits | Abrasion-Proof Bio-Certified Sleeves | Zero-Defect Inventory Mobilized

Precision-Etched Pharmaceutical Conduits | Abrasion-Proof Bio-Certified Sleeves | Zero-Defect Inventory Mobilized

Contact form

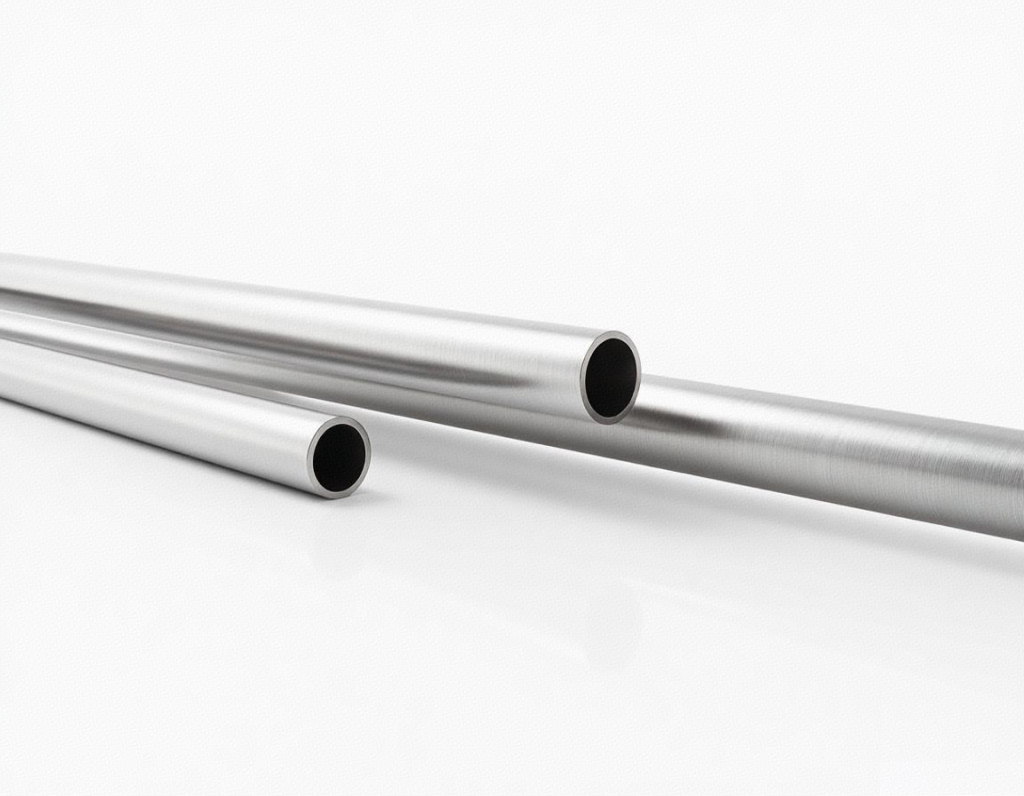

Precision-Engineered Tubing Solutions for Complex Installations

Crafted to ASTM standards with ±0.1%-0.3% tolerance, these stainless steel tubes feature a 120-mesh polished surface for minimized fluid resistance. The 316L/304L grades ensure exceptional corrosion resistance in chemical processing or marine environments, while the 1mm-100mm diameter range accommodates everything from microfluidic systems to industrial pipelines.

| Specification | Detail |

|---|---|

| Diameter Range | 1mm – 100mm |

| Material Grades | 304/304L/316L/310S/2205 |

| Surface Integrity | 120 Mesh Electrolytic Polishing |

| Pressure Rating of Schedule 10 Stainless Steel Pipe | 480 PSI – 1,200 PSI (varies by alloy) |

| Fabrication Services | CNC Bending, Laser Cutting, Flaring |

Expert Fabrication Techniques for Custom Projects

When how to bend a stainless steel pipe requires precision, our cold-rolling service achieves 1.5D bend radii without crimping, using mandrel-assisted CNC machinery. For cutting operations, the pipe cutter for stainless steel recommendation includes tungsten-carbide blade tools that prevent work hardening in 300-series alloys.

Durable Performance Metrics for Engineering Teams

The pressure rating of schedule 10 stainless steel pipe reaches 1,200 PSI in 316L grade (6-inch diameter), validated by hydrostatic testing at 1.5x MAOP. All tubes ship in seaworthy wooden crates (60x40x40cm) with 7-day global delivery and 1-ton MOQ flexibility, supporting rapid deployment in oil/gas or pharmaceutical projects.