ASTM-Certified Seamless Pipes | 304/316L/2205 Grades Available | 6-Meter Custom Cut Flexibility + Factory-Priced Bulk Supply

ASTM-Certified Seamless Pipes | 304/316L/2205 Grades Available | 6-Meter Custom Cut Flexibility + Factory-Priced Bulk Supply

Contact form

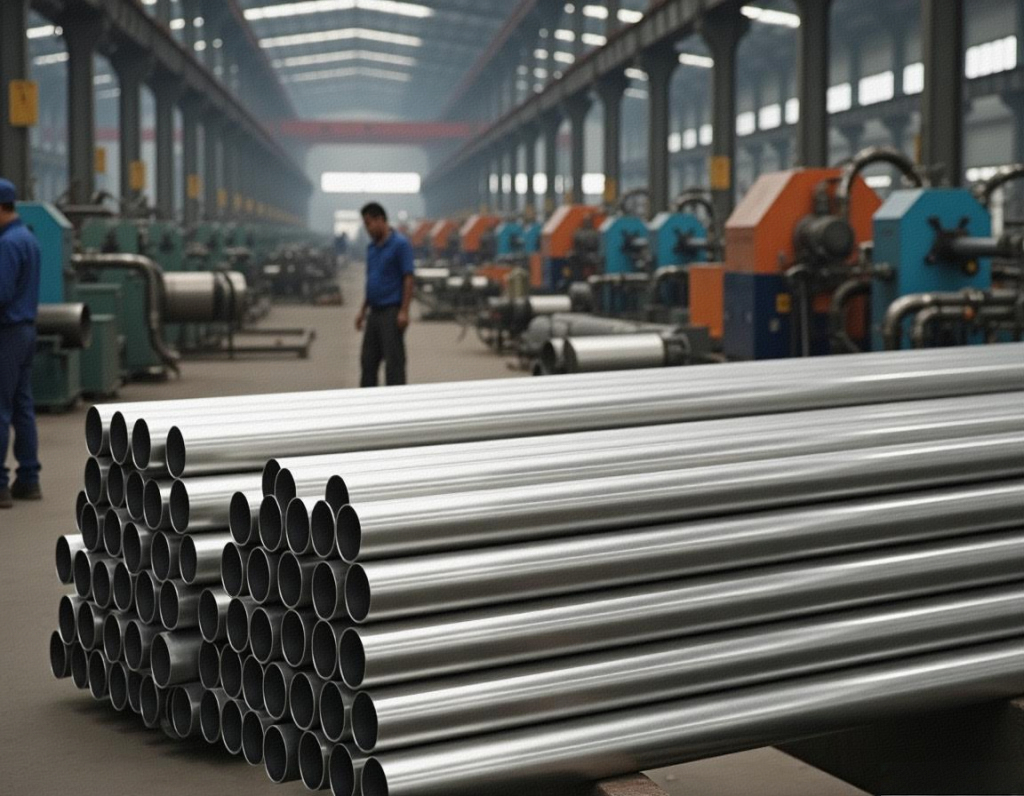

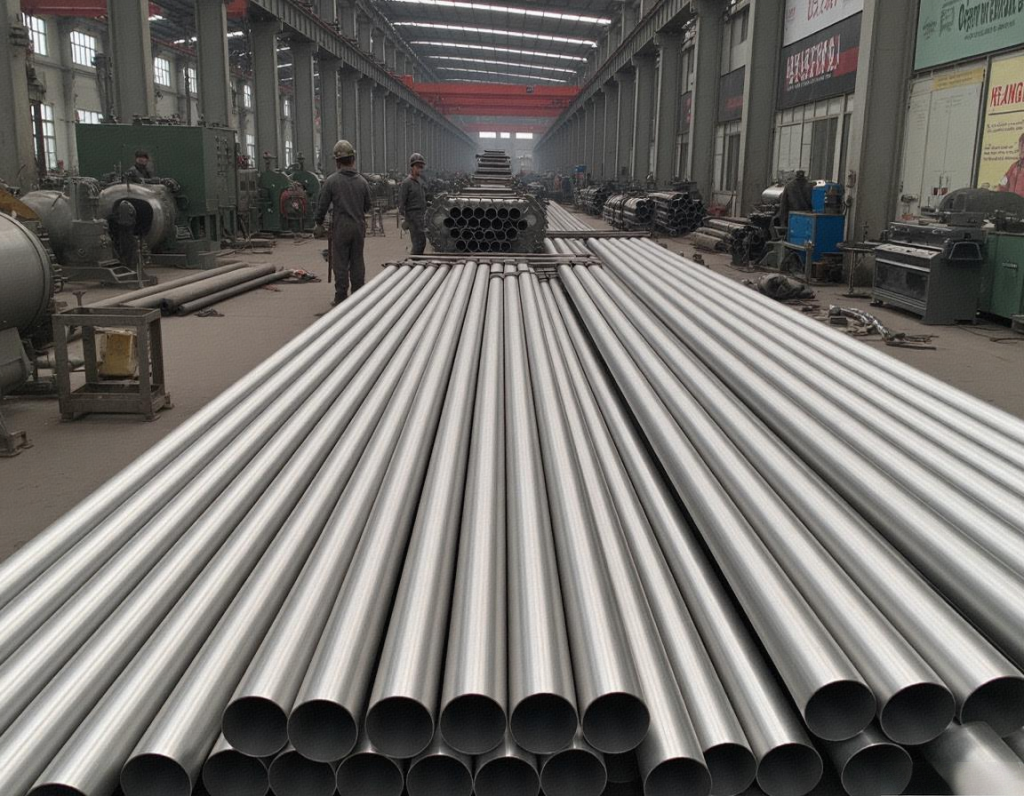

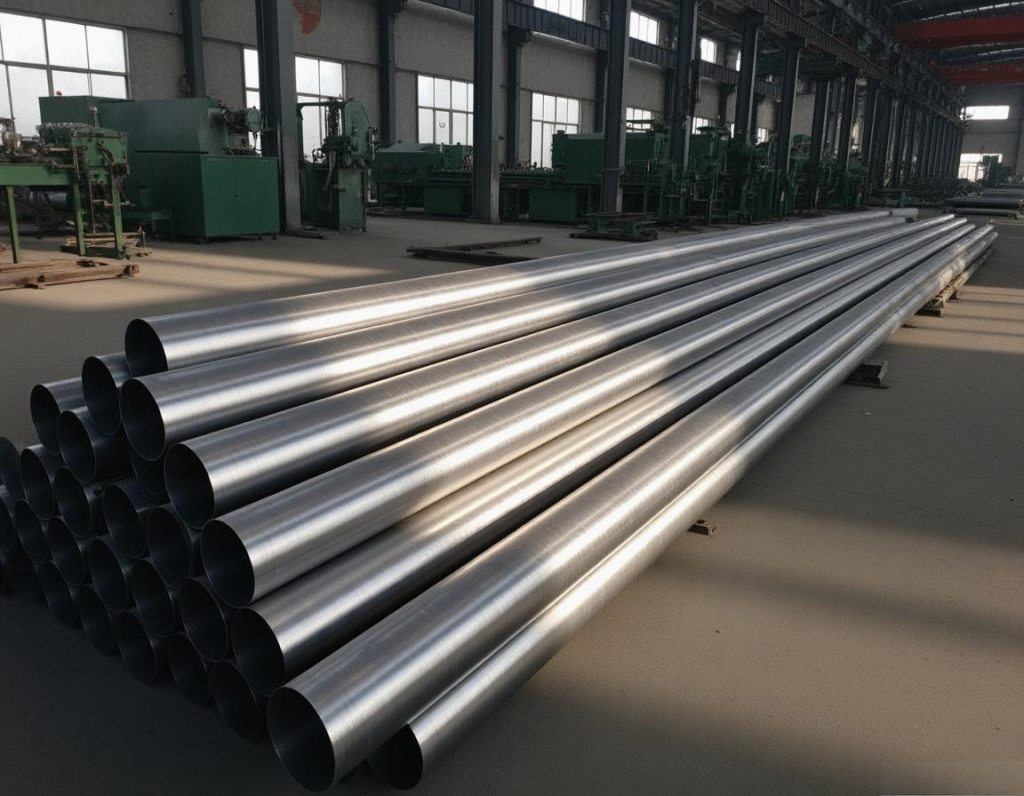

Precision-Engineered Stainless Steel Tubing Solutions

Crafted to ASTM standards with ±0.1%-0.3% dimensional accuracy, our stainless steel tubes excel in demanding environments. Ideal for 2 1/2 stainless steel exhaust pipe configurations, these round-profile tubes combine 2B surface finish and 120 mesh refinement for industrial aesthetics. Available in diameters from 1mm to 100mm, the 2 inch stainless steel exhaust pipe variant features 301L/304N/316Ti alloys, while 2.25 stainless steel exhaust pipe models leverage 310S/2205 grades for extreme heat resistance.

| Diameter Range | Material Options | Surface Treatment | Key Applications | Packaging Specs |

|---|---|---|---|---|

| 1mm–100mm | 304L/316L/321 | 120 Mesh Polish | Medical Systems | 60x40x40cm Crates |

| 25–50mm | 310S/410S | 2B Cold Rolled | Chemical Pipelines | 1000kg/Unit |

| 60–80mm | 2205 Duplex | Annealed Finish | Structural Frames | Weatherproof Wrap |

| 10–24mm | 301/410L | Passivated Layer | Exhaust Systems | Anti-Scratch Film |

| 85–100mm | 316Ti/441 | Brushed Texture | HVAC Ducting | Custom Palletizing |

Advanced Fabrication & Compliance

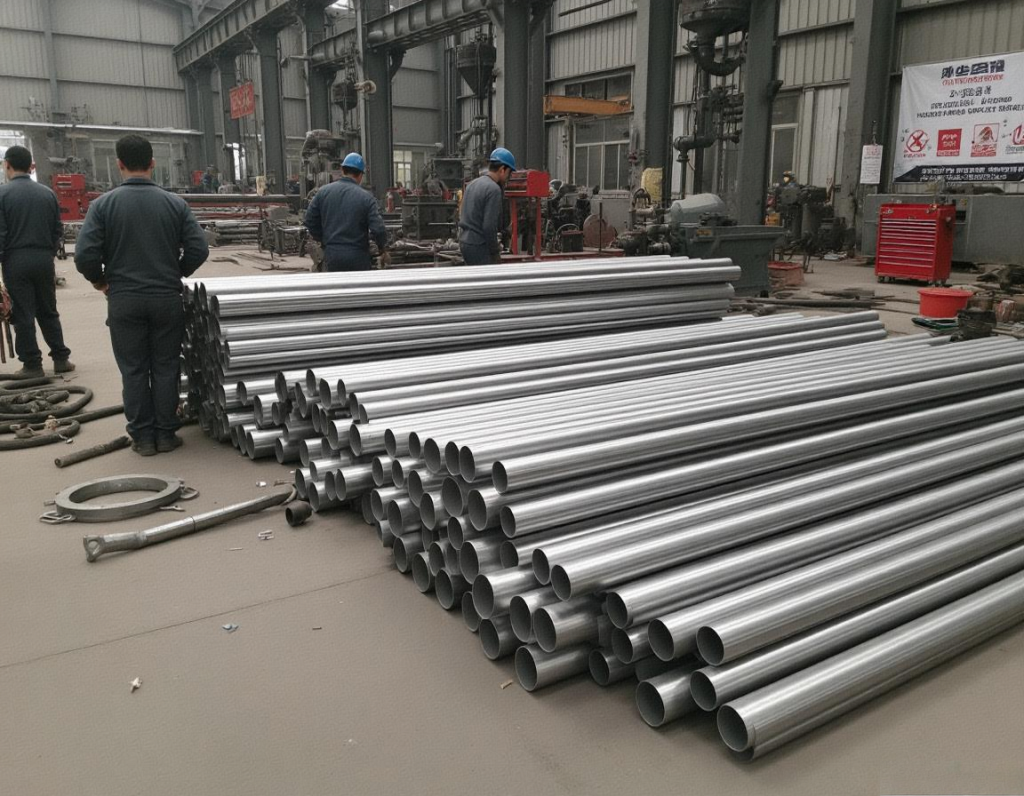

Engineered for construction structures and chemical industry applications, these tubes support bending, welding, and precision cutting. The seamless integration of strong corrosion resistance ensures reliability in marine and acidic environments. Modular lengths accommodate custom exhaust systems, while JIT manufacturing enables 7-day global delivery cycles.

Customization-Driven Supply Chain

Optimized for rapid deployment, our inventory includes decoiled and pre-punched variants compatible with 30%TT+70%TT payment terms. From medical equipment tubing to heavy-duty 1-ton MOQ orders, the 60x40x40cm seaworthy packaging guarantees damage-free transit. Explore alloy-specific solutions for temperature ranges from -29°C to 925°C, backed by ±0.2mm wall thickness consistency.