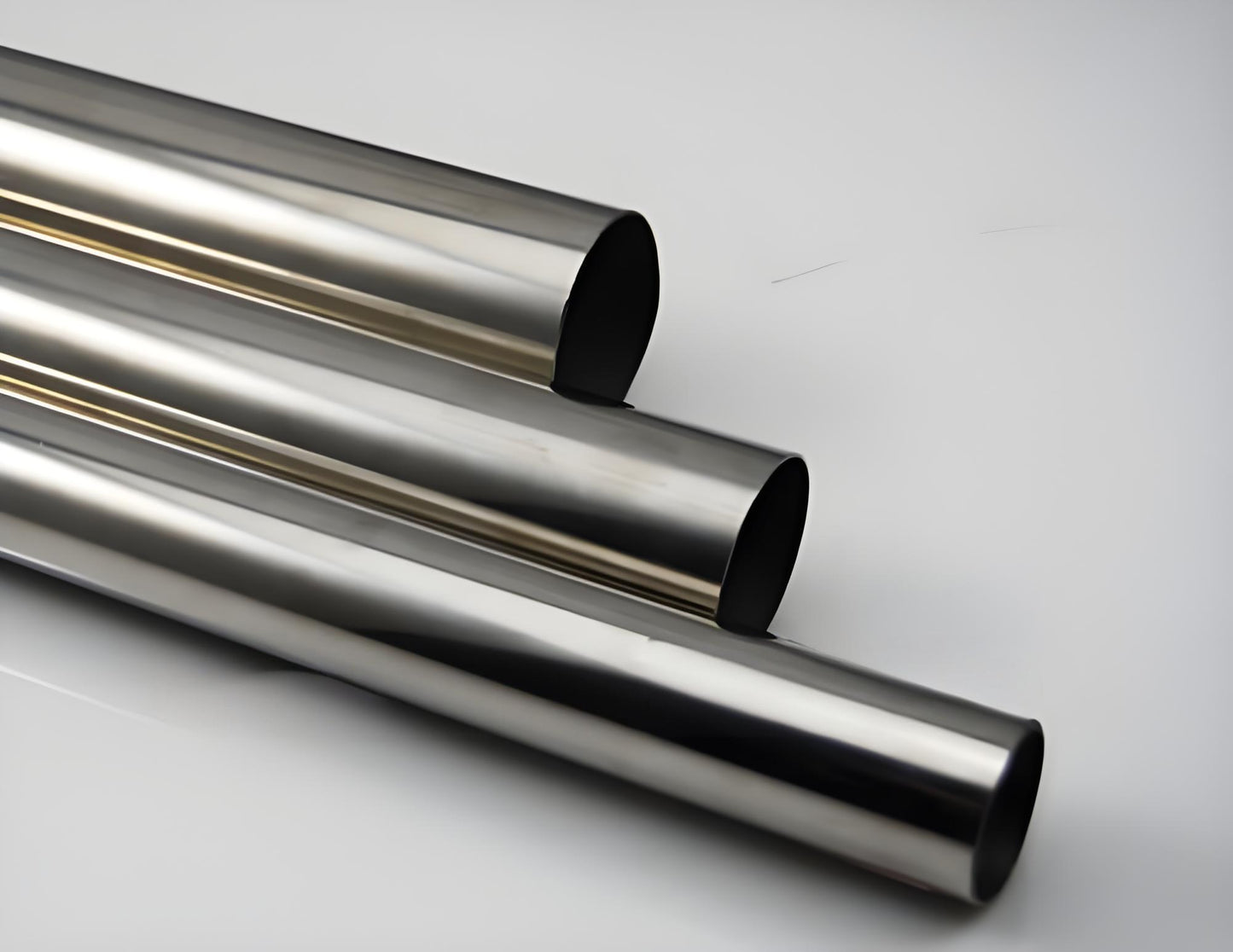

Schedule 80S DN50 Stainless Steel Pipe | Corrosion-Proof 304/316L Seamless, Custom Diameters 1mm-100mm

Schedule 80S DN50 Stainless Steel Pipe | Corrosion-Proof 304/316L Seamless, Custom Diameters 1mm-100mm

Contact form

Engineered for Extreme Conditions: Precision in Every Diameter

When industrial exhaust systems face scorching 950°C gases or coastal rigs battle salt-laden storms, the 4 in stainless steel exhaust pipe thrives. Forged from 310S or 316Ti alloys, its 101.6mm bore optimizes turbulent flow in turbocharged engines while resisting thermal fatigue cracks. For heavy-duty infrastructure, the 6 inch stainless steel pipe commands attention—its 152.4mm diameter channels crude oil through Arctic pipelines, with 2205 duplex walls shrugging off hydrogen-induced cracking. Even biogas plants rely on mirror-polished 6 inch stainless steel pipe networks, where electropolished 316L interiors (Ra ≤0.4μm) prevent methane-corrosive biofilm buildup.

Custom Fabrication for Mega-Scale Projects

Transform raw potential into industrial marvels: CNC-bend 4 in stainless steel exhaust pipe into sinuous refinery flare stacks, or laser-cut 6 inch stainless steel pipe into offshore platform risers. For geothermal energy farms, 441-grade coils become mile-long heat exchanger loops, their 1mm~100mm diameter range adapting to subterranean extremes. Automotive engineers reimagine the 6 inch stainless steel pipe as intercooler ducts, mandrel-formed to 3D contours without wall thinning. Decoiling services yield straight-length 304N tubes for pharmaceutical CIP systems, while TIG-welded 321 alloy manifolds maintain ultrahigh vacuum integrity in semiconductor fabs.

Global Logistics, Engineered for Speed

Armored against transcontinental chaos: 60x40x40cm crates cocoon 4 in stainless steel exhaust pipe segments in VCI paper, surviving monsoons and desert crossings. MOQ flexibility lets power plants order 50-ton spools of 6 inch stainless steel pipe alongside racetracks sourcing polished 304L exhaust tips. Seven-day sprints from plasma cutting to port dispatch keep mega-projects on track; payment terms (30% TT advance) balance cashflow for startups and Fortune 500s. Traceability? Uncompromised: Mill certs validate molybdenum content in every 6 inch stainless steel pipe, while 3D weld maps confirm ASME B31.3 compliance—because global ambition demands precision without excuses.