1

/

of

6

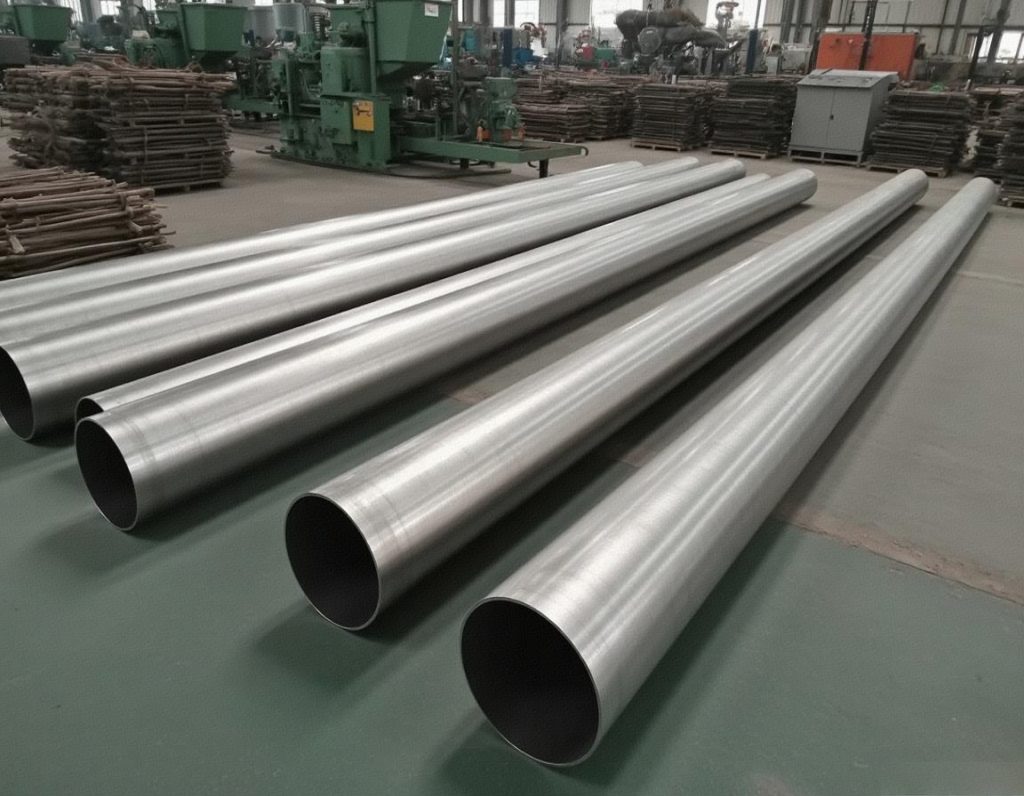

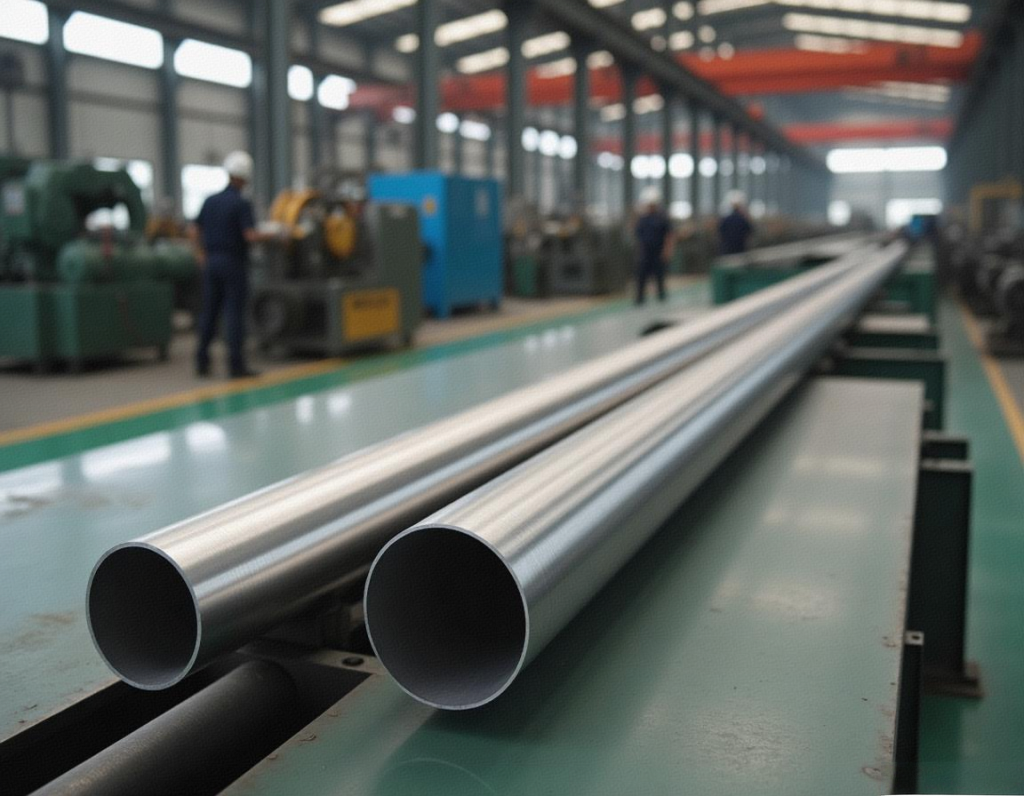

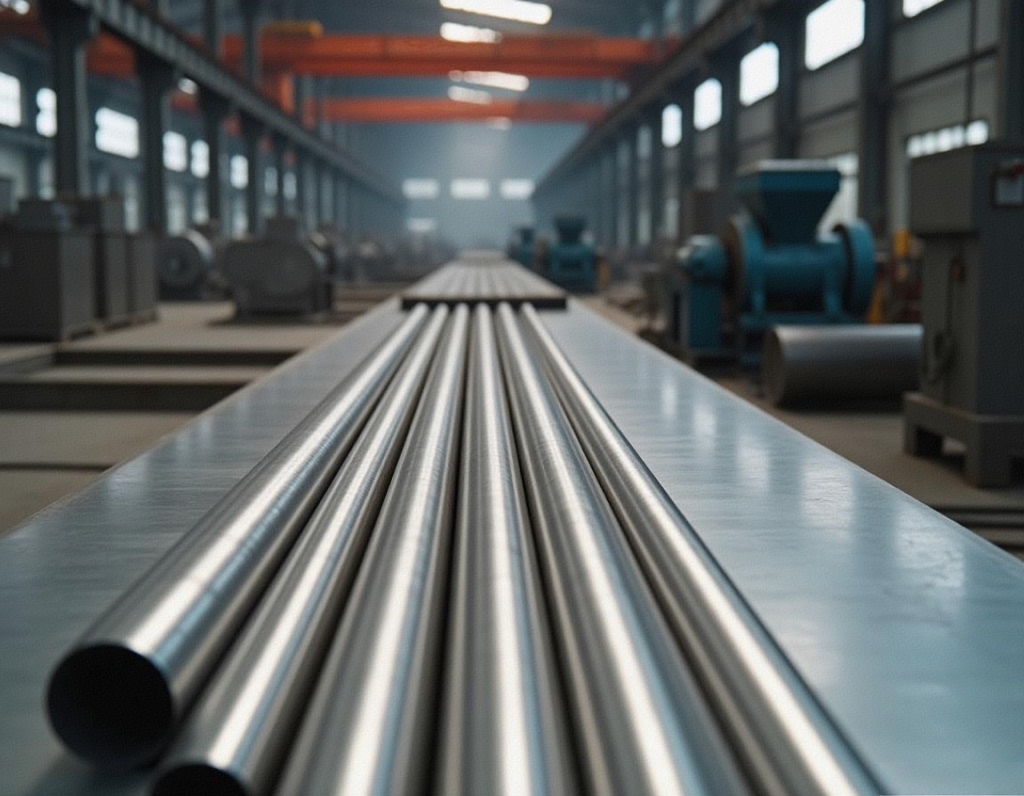

ASTM-Certified 304/316L/2205 Welded Pipes 6m Pre-Cut Lengths | Factory Direct Pricing | SCH40/SCH80 Sizes | Corrosion Resistant

ASTM-Certified 304/316L/2205 Welded Pipes 6m Pre-Cut Lengths | Factory Direct Pricing | SCH40/SCH80 Sizes | Corrosion Resistant

Contact form

| Material Grade | Diameter | Application | Surface Finish | Processing |

|---|---|---|---|---|

| 316L | 20–80 mm | Chemical Processing | 2B | Welding, Bending |

| 304N/304L | 3.5" Exhaust | Automotive Systems | Polished | Cutting |

| 310S/321 | 1–50 mm | High-Temperature Lines | 120 Mesh | Decoiling |

| 2205 Duplex | 8" Pipe | Marine Engineering | Pickled | Punching |

| 410/410S | Custom | Structural Frameworks | Hairline | Coil Forming |

Durable 8 stainless steel pipe solutions with 1.5–12mm wall thickness, compliant with ASME B36.19 specifications. Pre-cut 6m lengths or custom sizes available, featuring hydrostatic testing up to 6,000 PSI for industrial safety.

Versatile 3.5 stainless steel exhaust pipe options include dual-wall insulated designs, reducing thermal loss in high-performance engines. All tubes ship in reinforced wooden crates, ensuring damage-free global logistics with 7-day lead times and flexible payment terms.

Key Technical Specifications:

- 316L stainless steel pipe: Max chloride resistance up to 2000 ppm, ideal for coastal applications.

- 3.5 stainless steel exhaust pipe: 409/304 hybrid options, TIG-welded seams for leak-proof performance.

- 8 stainless steel pipe: SCH40–SCH160 wall thickness, ANSI B16.5 flange compatibility.

Compliance & Testing:

- ASTM A312 (Welded) / A269 (Seamless)

- Hydrostatic Test Pressure: 1.5x working pressure

- Surface Roughness: Ra ≤ 0.8μm (120 grit equivalent)

- MOQ: 1 ton with 30% TT deposit