ASME-Certified DN50 Seamless Pipes | 316L/2205 Alloy for Chemical Transport + Precision-Cut to Spec

ASME-Certified DN50 Seamless Pipes | 316L/2205 Alloy for Chemical Transport + Precision-Cut to Spec

Contact form

Engineered Resilience for Extreme Thermal Demands

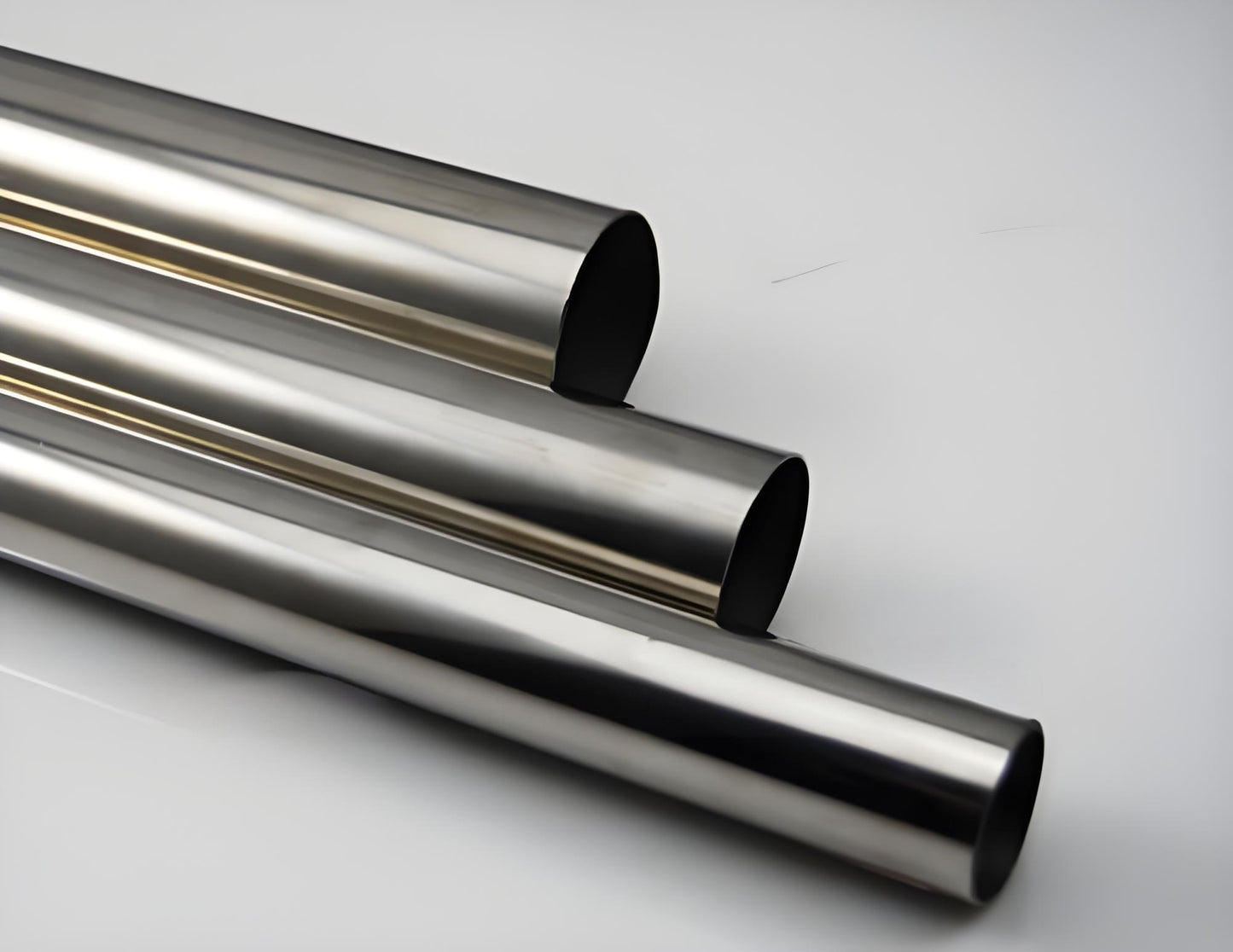

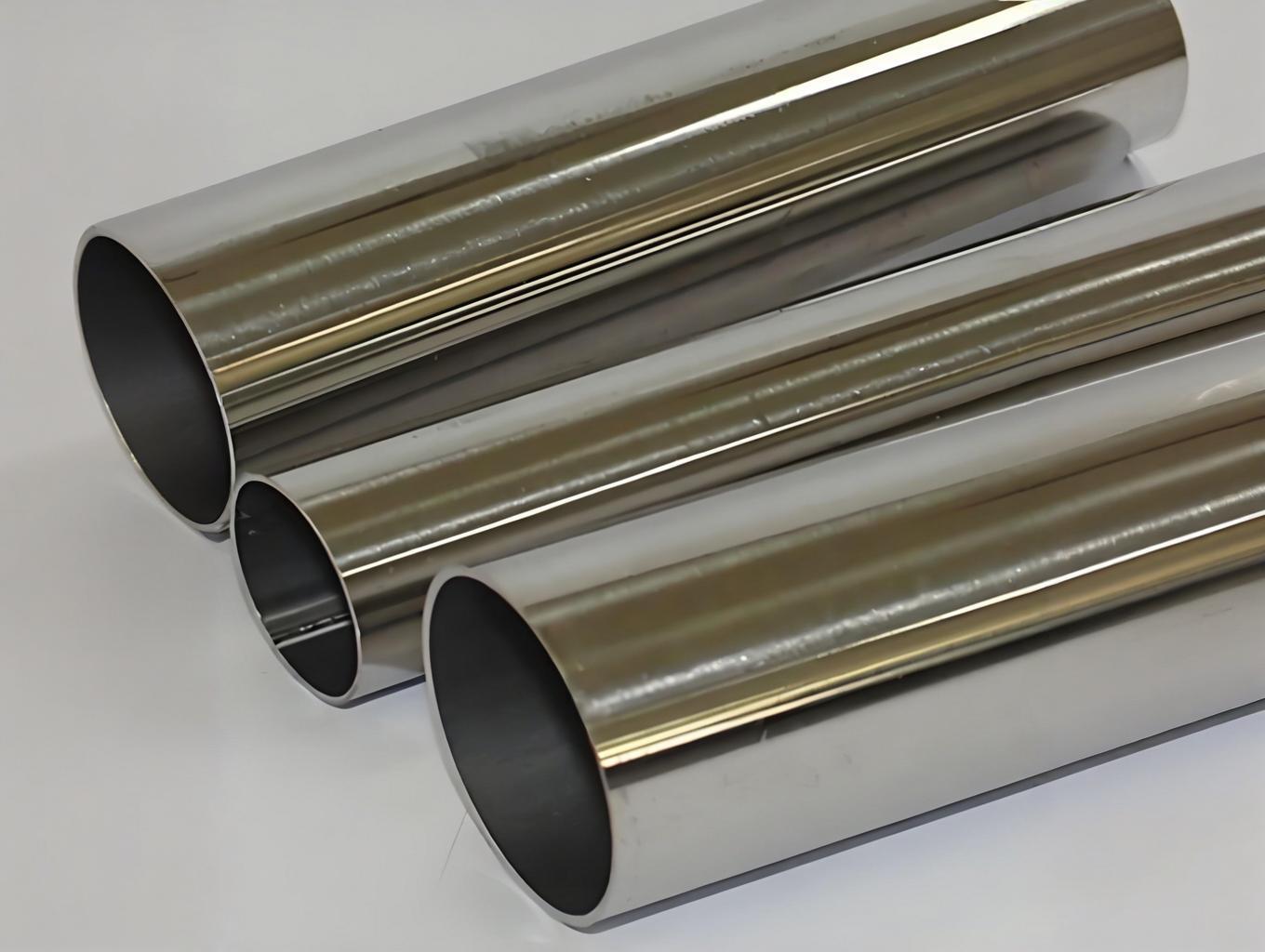

When turbocharged engines roar or industrial incinerators blaze at 900°C, the 3 stainless steel exhaust pipe kit delivers unwavering performance. Crafted from 310S or 316Ti alloys, these pre-fab systems include mandrel-bent J-pipes and V-band clamps, reducing installation time by 60% while resisting thermal fatigue. For hydraulic systems demanding precision, the 3/4 stainless steel pipe (19.05mm OD) in 304N maintains ±0.15% ovality under 2,500 PSI, its 2B surface finish (Ra ≤0.6μm) minimizing turbulent flow. Even wastewater treatment plants rely on 3in stainless steel exhaust pipe networks, where 2205 duplex variants combat hydrogen sulfide corrosion across decades of service.

Precision Fabrication for Complex Configurations

Transform raw material into mission-critical architectures: Laser-cut the 3/4 stainless steel pipe into microfluidic cooling loops for data centers, or CNC-bend 441-grade coils into seismic-resistant supports. The 3 stainless steel exhaust pipe kit shines in biogas scrubbers—corrugated flex sections absorb vibration from 20HP compressors, while TIG-welded 321 alloy flanges handle 10^-8 mbar vacuums. For automotive enthusiasts, the 3in stainless steel exhaust pipe becomes a showpiece, mirror-polished to 120-grit perfection and paired with slash-cut tips. Decoiling services produce straight-length 304L tubes for pharmaceutical CIP systems, their electropolished interiors (Ra ≤0.4μm) meeting FDA CFR 21 compliance.

Agile Global Logistics for Time-Sensitive Projects

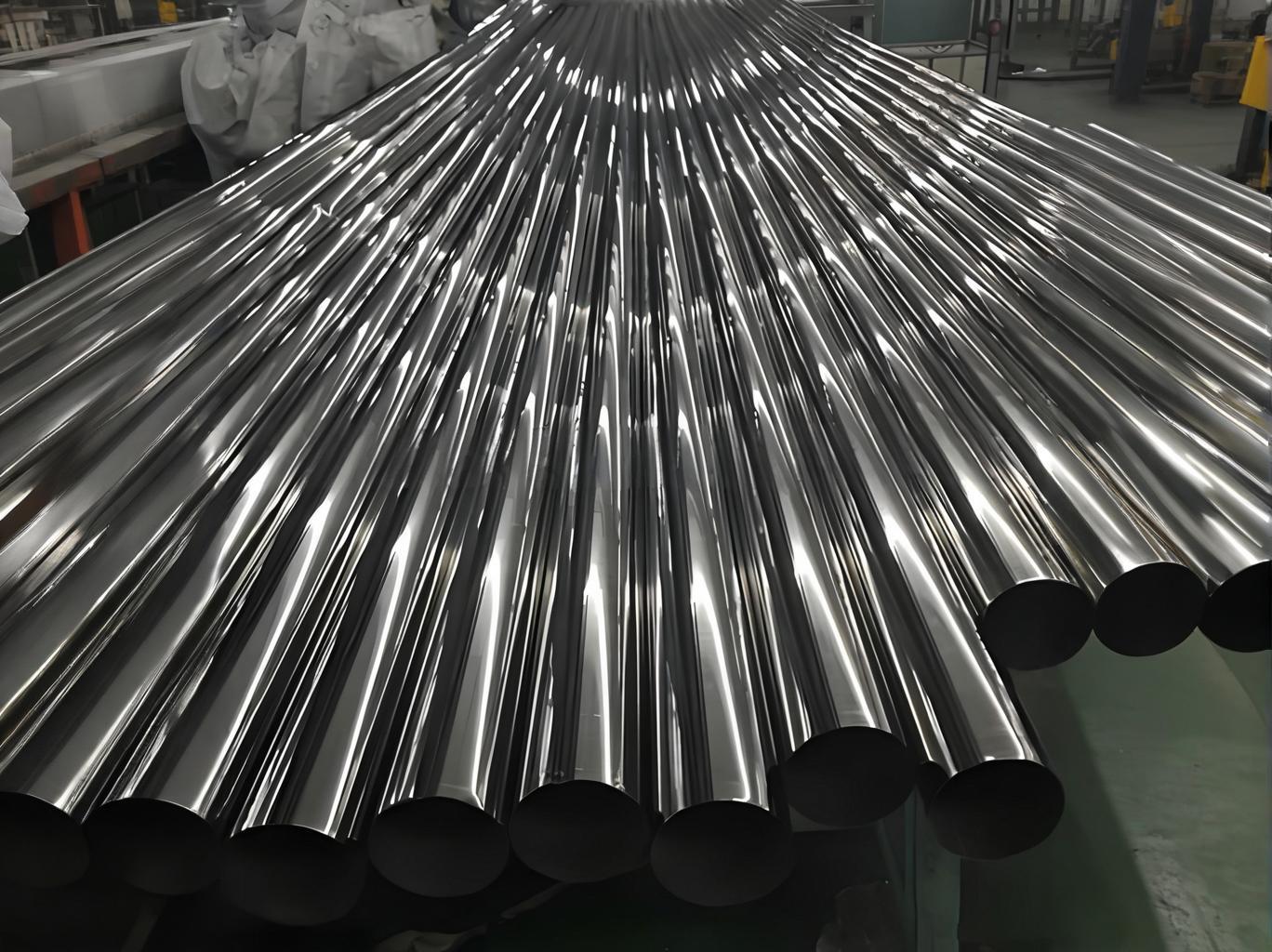

Armored against planetary abuse: 60x40x40cm crates cocoon 3in stainless steel exhaust pipe segments in VCI paper, surviving transoceanic humidity and Arctic freezes. MOQ flexibility lets race teams order 10-foot 3 stainless steel exhaust pipe kit bundles alongside oil refineries sourcing 50-ton 2205 duplex spools. Seven-day sprints from plasma cutting to dispatch keep construction projects on-schedule; payment terms (30% TT advance) accommodate startups and conglomerates alike. Traceability is paramount: Mill certs validate molybdenum content in 3/4 stainless steel pipe batches, while 3D weld maps confirm every 3in stainless steel exhaust pipe meets ASME B31.3 curvature specs—because global infrastructure demands precision at scale.