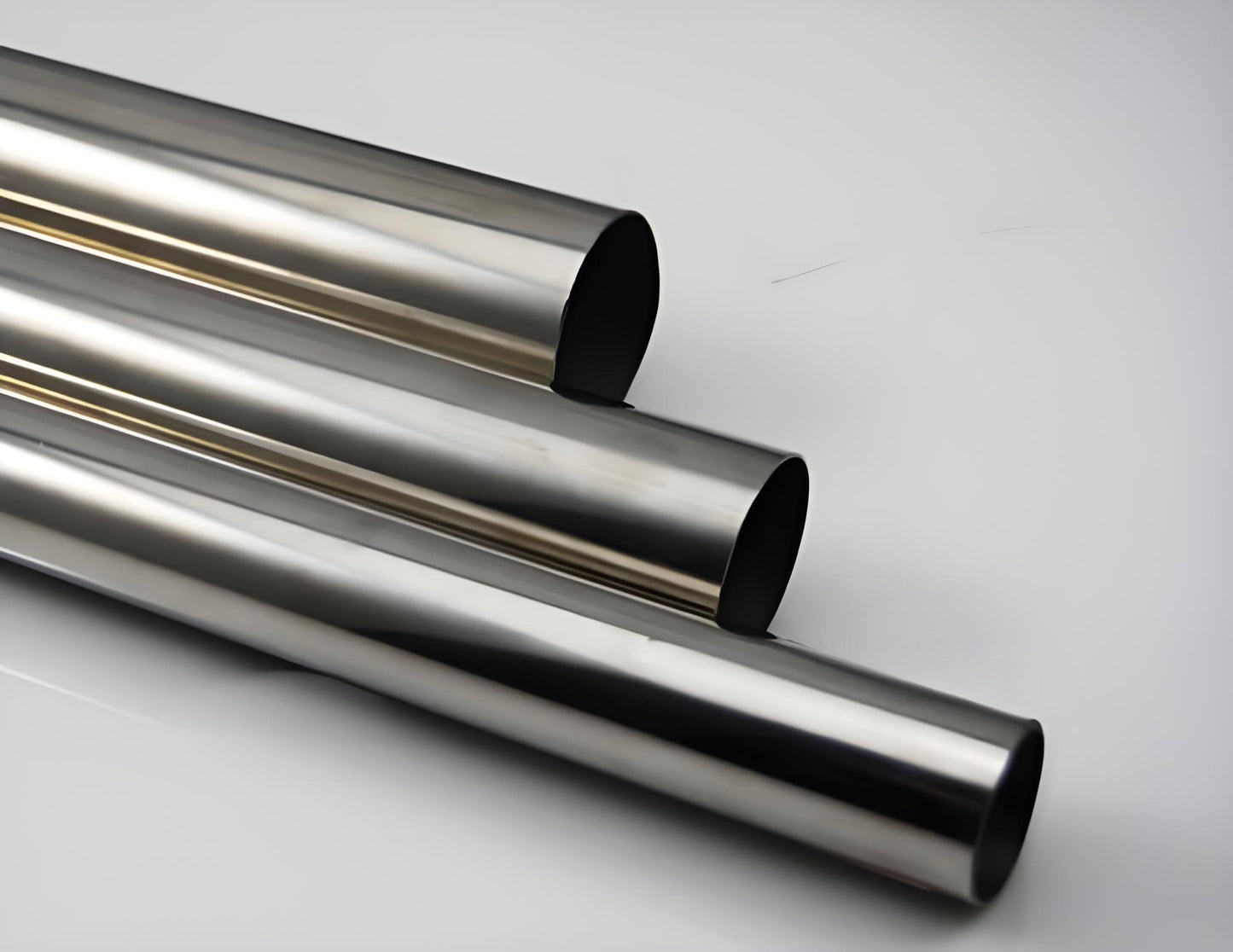

DN40 ASTM 304/316L/2205 Seamless Pipe | High-Temperature Resistant Industrial Tubing + Global Stock

DN40 ASTM 304/316L/2205 Seamless Pipe | High-Temperature Resistant Industrial Tubing + Global Stock

Contact form

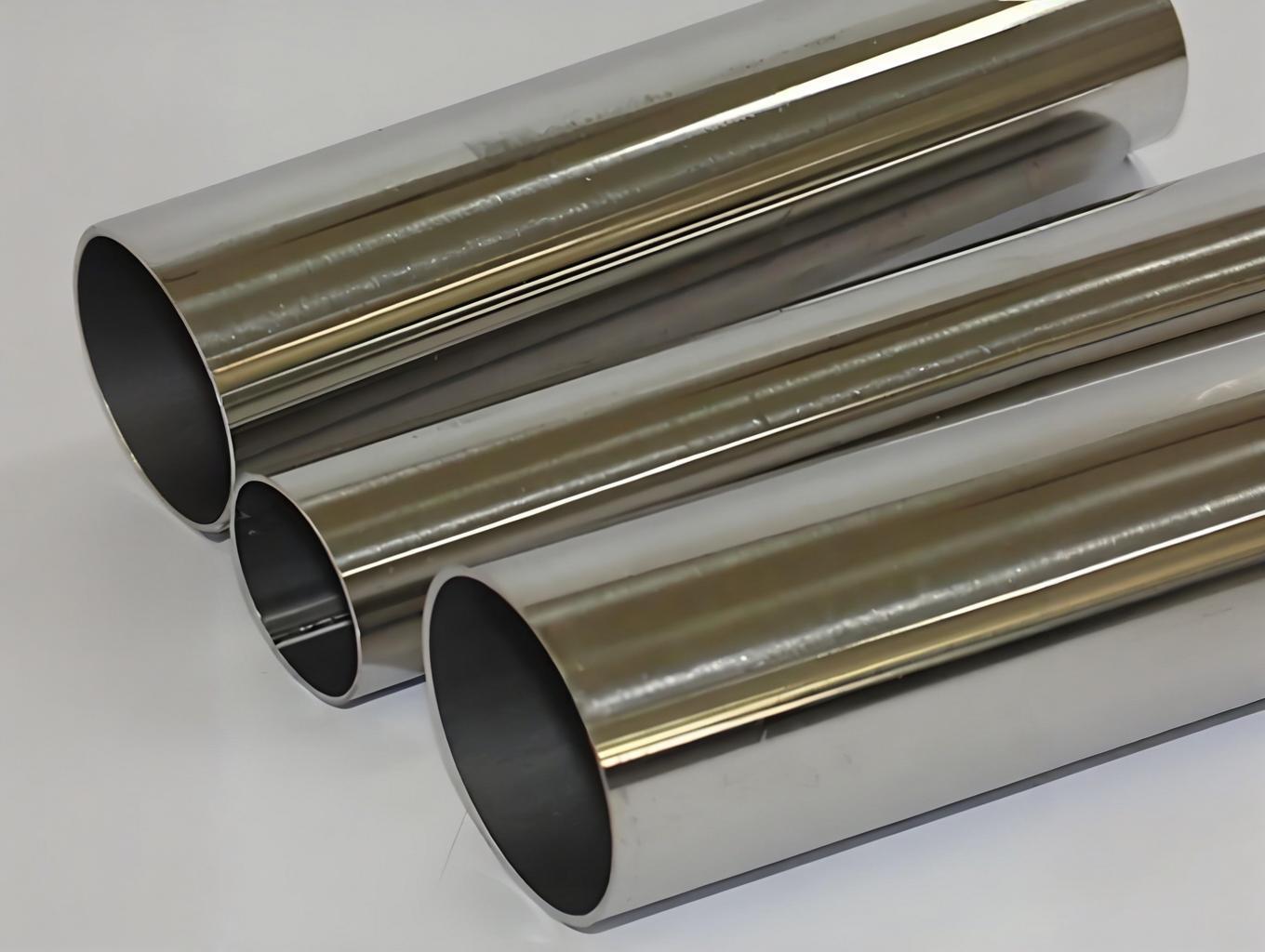

Unrivaled Performance in Extreme Environments

When industrial chimneys belch acidic plumes or offshore platforms battle salt-laden gales, 10 inch stainless steel pipe stands unyielding. Forged from 316Ti or duplex 2205 alloys, these behemoths navigate sulfuric acid mists in scrubbers while tolerating ±0.2% dimensional drift across 40-foot spans. Automotive engineers revere the 2.5 inch 304 stainless steel exhaust pipe—its 63.5mm bore optimizing backpressure in turbocharged systems, 2B surface finish (Ra ≤0.6μm) resisting carbon buildup. Even the harshest LNG terminals rely on 3 inch stainless steel exhaust pipe kit assemblies, where pre-fab flanges and V-band clamps slash installation times by 70%.

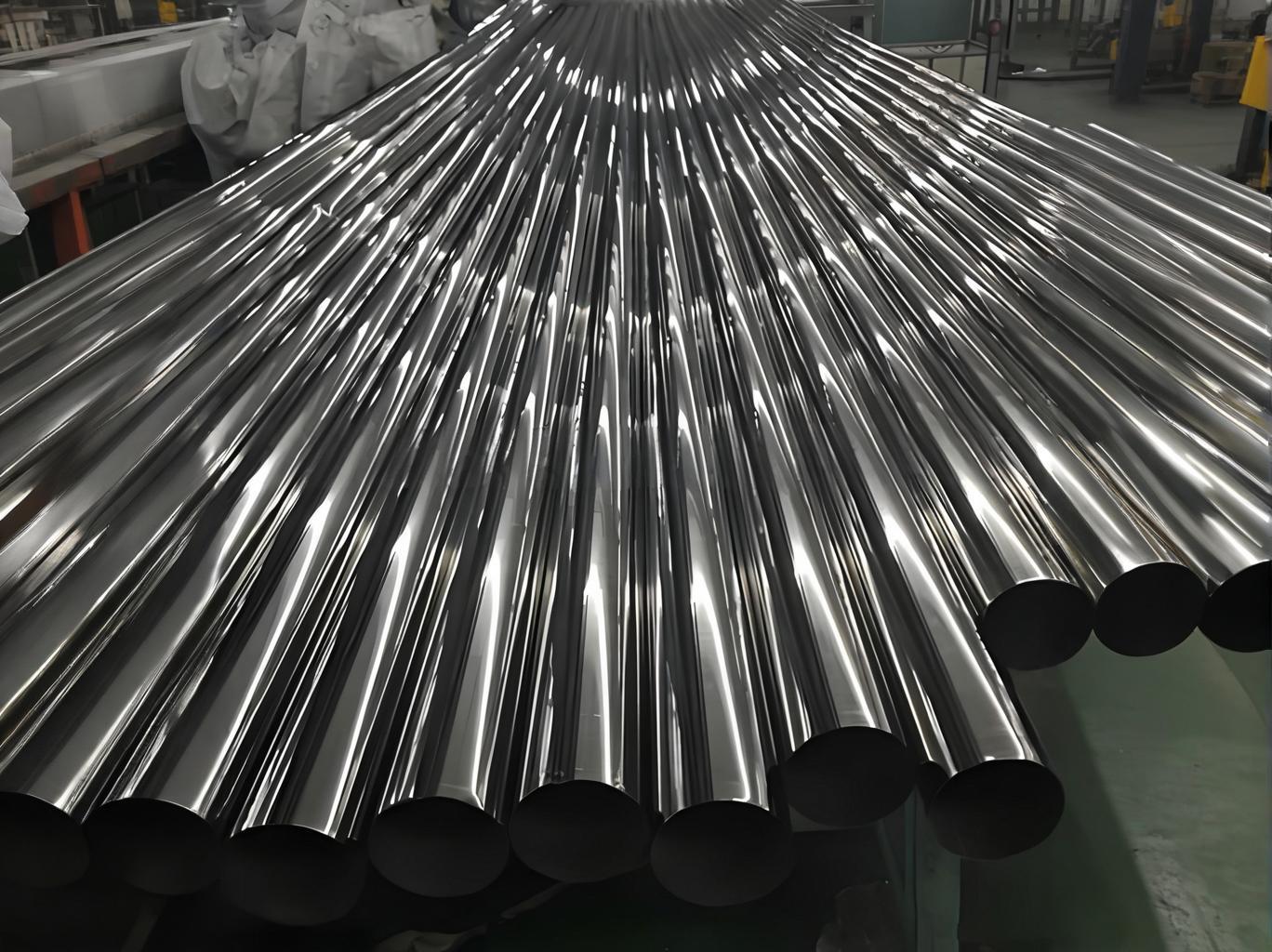

Precision-Engineered Exhaust Solutions

From diesel-powered generators to hydrogen fuel cell stacks, customization reigns. The 2.5 inch 304 stainless steel exhaust pipe morphs into mandrel-bent J-tubes for marine engines, its 304 alloy shrugging off 950°C thermal cycling. For heavy-duty fleets, 3 inch stainless steel exhaust pipe kit bundles include laser-cut brackets and TIG-welded flex joints, absorbing 20G vibration loads without cracking. Decoiling services transform 441-grade coils into 10-meter straight runs of 10 inch stainless steel pipe, ideal for geothermal venting—their 250mm ID accommodating 30,000 CFM airflow at 85% efficiency.

Global-Ready Systems, Precision-Packaged

Armored against planetary abuse: 60x40x40cm crates cocoon 3 inch stainless steel exhaust pipe kit components in anti-corrosion VCI paper, surviving monsoons and desert crossings. MOQ flexibility lets mining giants order 50-foot 10 inch stainless steel pipe segments alongside tuners sourcing polished 2.5 inch 304 stainless steel exhaust pipe for show cars. Seven-day sprints from CNC plasma cutting to dispatch keep refinery turnarounds on-schedule; payment terms (30% TT upfront) lubricate cashflow for startups and conglomerates alike. Traceability? Ironclad: Mill certs validate molybdenum content; 3D weld maps confirm every 10 inch stainless steel pipe meets ASME B31.3 curvature specs—because global infrastructure demands perfection in scale.