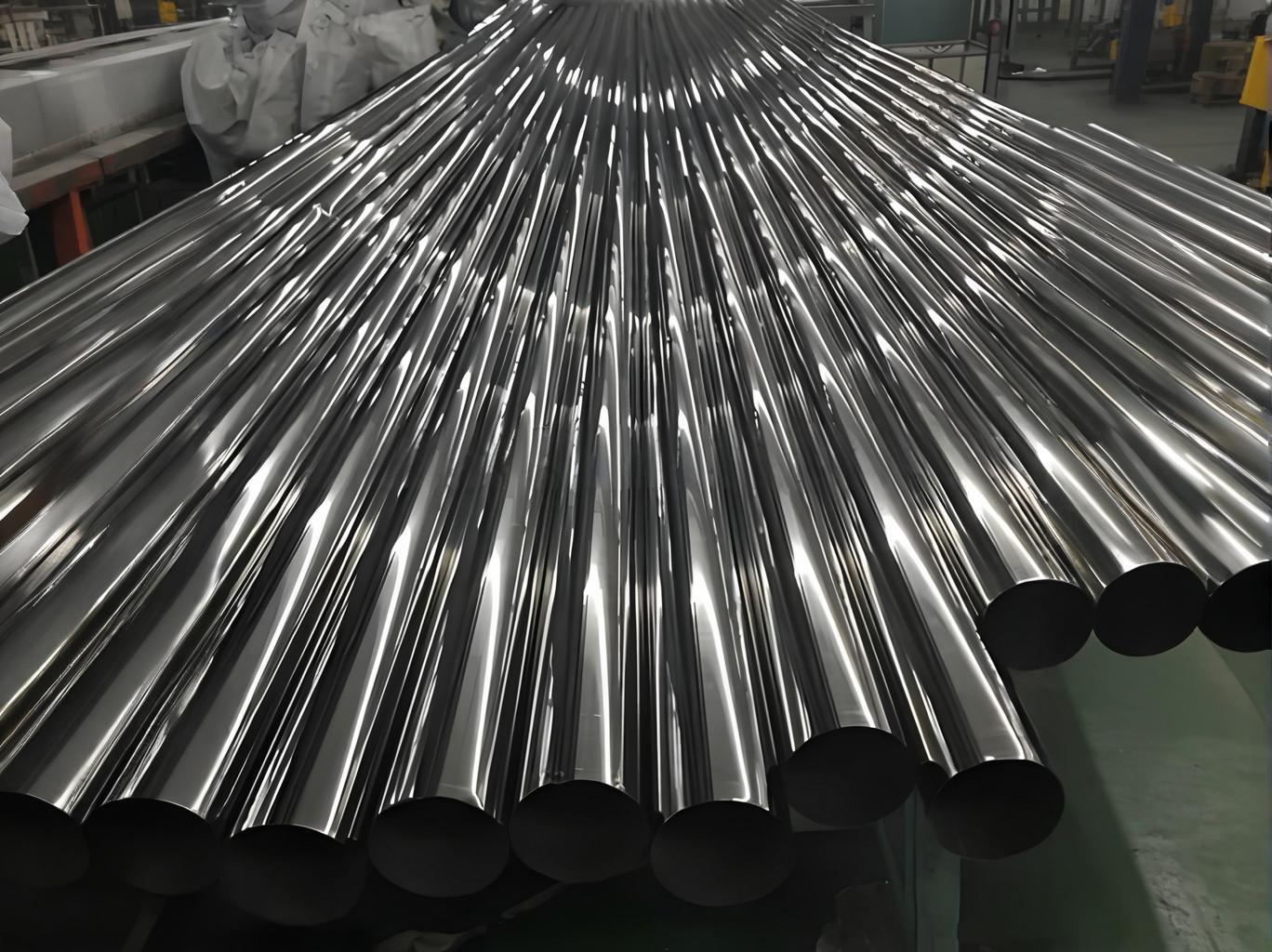

ASTM-Certified 304/316L/2205 Seamless Pipes | DN20 Precision Tubing, Mirror Finish + Corrosion Proof

ASTM-Certified 304/316L/2205 Seamless Pipes | DN20 Precision Tubing, Mirror Finish + Corrosion Proof

Contact form

Uncompromising Performance for Extreme Environments

From the blistering heat of automotive stainless steel exhaust flex pipe systems to the caustic depths of chemical processing plants, these tubes defy degradation. Forged from 316Ti or 310S alloys, they shrug off thermal cycling between -50°C and 1,100°C while maintaining ±0.2% dimensional stability. Whether crafting a 3-inch stainless steel pipe diameters for brewery wort circulation or a 100mm conduit for offshore oil rigs, the 2B surface finish (Ra ≤0.8μm) minimizes friction loss. Electropolished 304L variants even meet FDA standards for pharmaceutical slurry transport, their 120-mesh interiors resisting bacterial adhesion.

Engineered Precision from Raw Material to Final Assembly

Every stainless steel pipe manufacturer must balance artistry with rigor. Cold-drawn 441-grade coils transform into seismic-resistant structural braces via CNC bending, while laser-cut 321 sheets become perforated filters for desalination plants. Decoiling services produce straight-length tubes for architectural handrails; TIG welding ensures hermetic seals in vacuum chambers. For automotive tuners, the stainless steel exhaust flex pipe emerges—corrugated 409L segments absorbing engine vibration without cracking. Custom diameters (1mm–100mm) accommodate microfluidic lab-on-chip devices and geothermal well casings alike.

Global-Ready Solutions with Surgical Precision

Crates engineered for chaos: 60x40x40cm wooden fortresses shield 1-ton batches of annealed 316L tubes from monsoons to desert storms. MOQ flexibility lets shipyards order 2205 duplex piping alongside labs sourcing 5mm capillary arrays. Need a stainless steel pipe diameters overhaul? Specify metric or imperial units—DN15 to DN500 schedules ship within 7 days, payment terms split 30% upfront and 70% pre-dispatch. Traceability is non-negotiable: mill certificates validate chromium content; 3D bend diagrams confirm every stainless steel exhaust flex pipe meets ASME B16.9 curvature specs. From cryogenic LNG transfer lines to sulfuric acid vent stacks, logistics scale with your ambition.