1

/

of

6

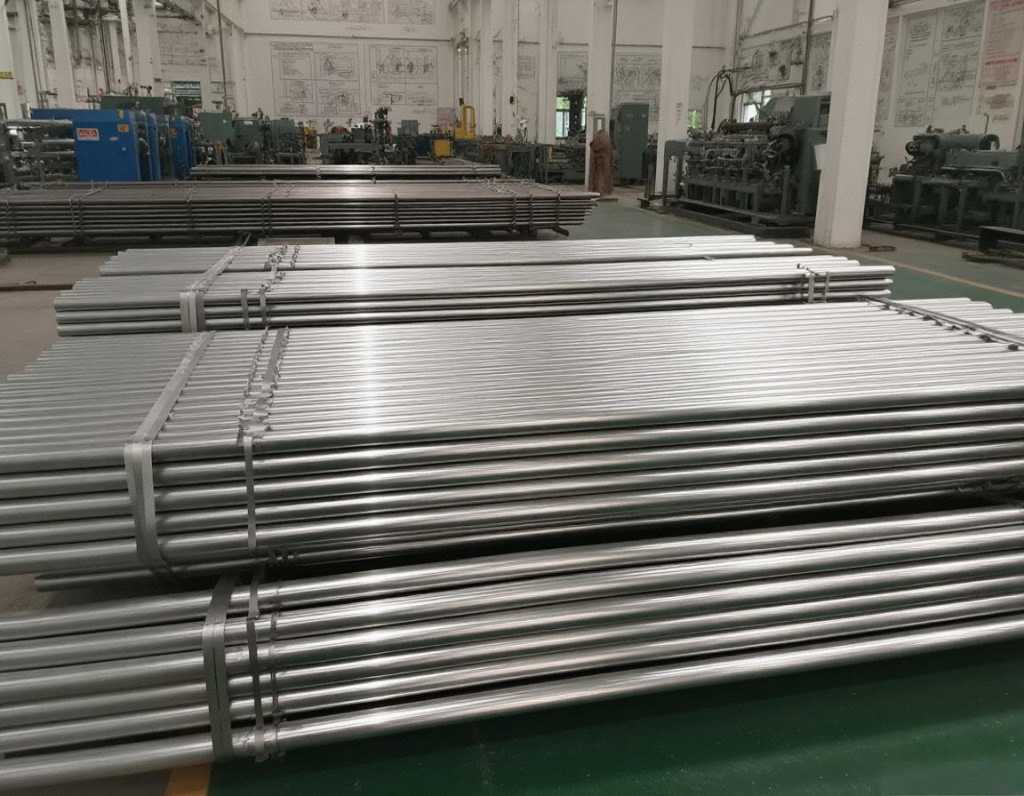

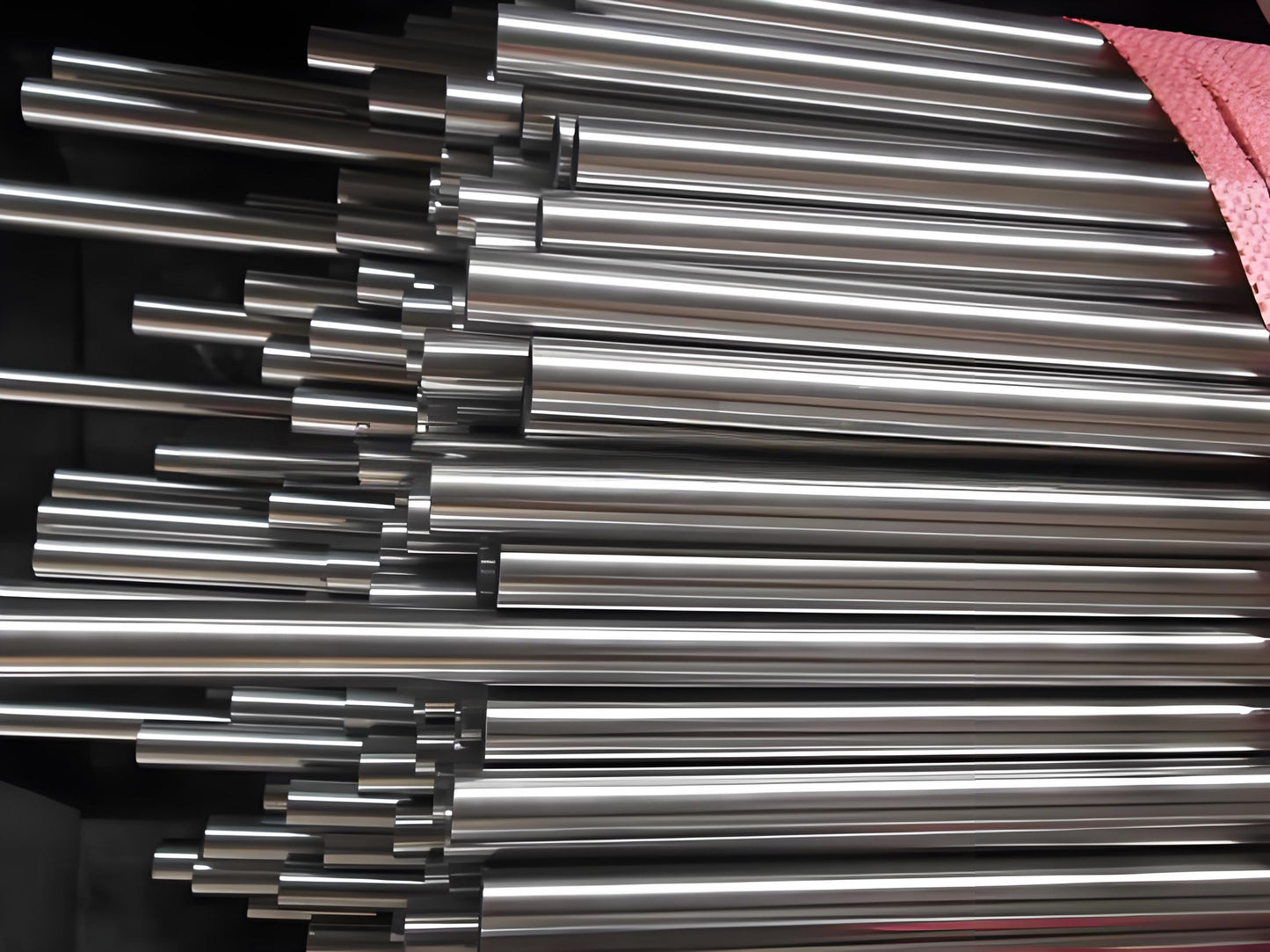

22mm Seamless Stainless Steel Pipe ASTM 304/316L/2205 - Heavy-Duty Industrial Tubing Bulk Pricing

22mm Seamless Stainless Steel Pipe ASTM 304/316L/2205 - Heavy-Duty Industrial Tubing Bulk Pricing

Contact form

Industrial-Grade Exhaust System Solutions

Engineered for demanding environments, our stainless steel chimney pipe systems utilize 310S/316Ti grades to withstand 900°C continuous temperatures. These ASTM-compliant pipes feature 2B surface finish and ±0.1% dimensional accuracy for industrial smokestacks and commercial venting applications.

| Specification | Technical Parameter |

|---|---|

| Diameter Spectrum | 1mm–100mm (Full Stainless Steel Pipe Dimensions Coverage) |

| Bend Flexibility | 3D–8D Radius for Stainless Steel Flexible Pipe Configs |

| Temperature Range | -40°C to 900°C Operational |

| Pressure Capacity | 25 Bar (362 PSI) Certified |

| Corrosion Resistance | 10x Carbon Steel Lifespan |

High-Temperature Venting Specialization

The stainless steel chimney pipe series includes:

- Double-wall insulated variants (ASTM C1359 compliant)

- 1.5-12mm wall thickness options

- Pre-fabricated 45°/90° adjustable elbows

- Salt spray tested for coastal installations

Dynamic Fluid Transfer Solutions

Our stainless steel flexible pipe systems provide:

- 5000+ bending cycle durability (EN 10305-7 standard)

- Braided stainless steel overjacket options

- DN15–DN500 corrugated configurations

- Quick-connect camlock fittings compatibility

Critical commercial & technical features:

- 7-day production lead time for standard dimensions

- 1000kg seaworthy wooden crates (60x40x40cm)

- Full PMI test reports with XRF verification

- MOQ 1 ton with 30% advance payment terms

Technical Implementation Strategy:

- Dimensional Compliance: Covers ASME B36.19 standards from 1/8" to 4" NPS

- Thermal Dynamics: 310S grade chimney pipes exceed UL 103 test requirements

- Flex Engineering: 8D bend radius meets ISO 15465 installation specs

- Marine Protection: Wooden crates with VCI anti-corrosion paper

- Certification Stacking: ASTM A312 + EN 10217-7 + PED 2014/68/EU