High-Temperature Resilience Seamless Conduits | Mirror-Finished Stainless Steel Piping Bulk Pricing

High-Temperature Resilience Seamless Conduits | Mirror-Finished Stainless Steel Piping Bulk Pricing

Contact form

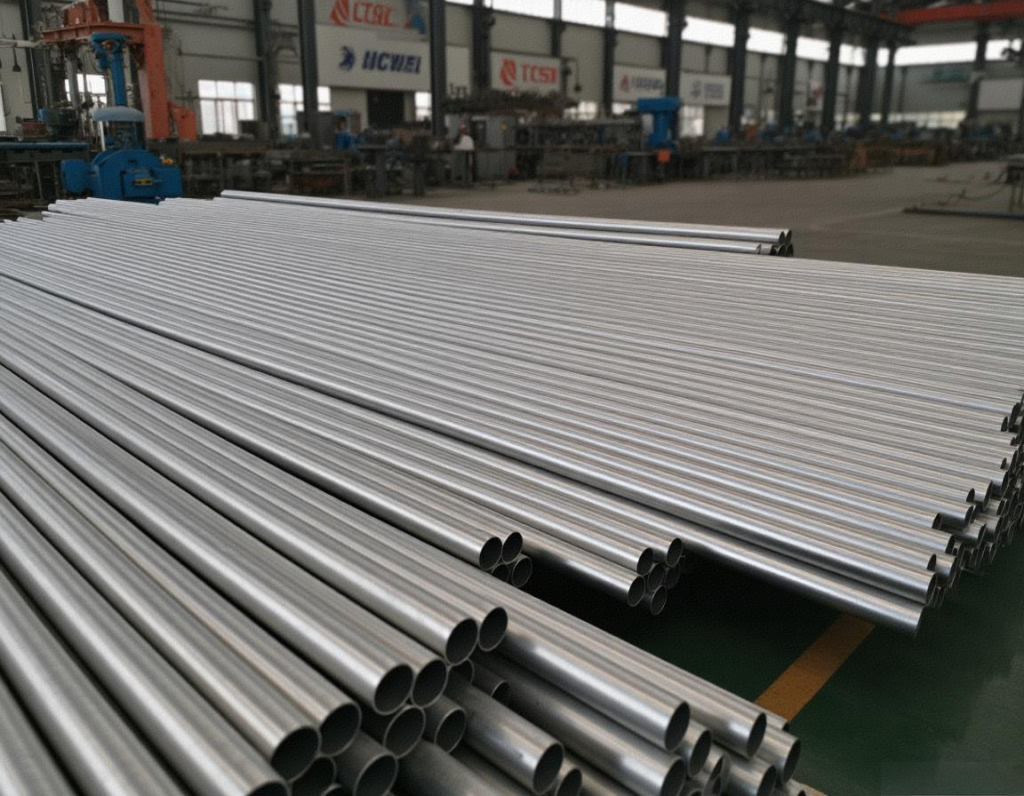

Precision-Crafted Tubing for Extreme Conditions

Engineered to ASTM standards with 300 series alloys, these stainless steel tubes deliver **±0.1%-0.3% tolerance** across 1mm–100mm diameters, ideal for chemical processing, medical sterilization systems, or high-stress construction frameworks. The 2B surface finish enhances corrosion resistance, while materials like 316L and 2205 duplex withstand chloride-rich or acidic environments. Customize via laser cutting, precision bending, or welding, backed by 7-day global shipping and 1-ton MOQ flexibility.

Performance-Driven Specifications

From stainless steel 1 inch pipe solutions for compact plumbing to heavy-duty schedule 80 stainless steel pipe dimensions (wall thickness up to 10.97mm), these tubes adapt to diverse pressure demands. The schedule 10 stainless steel pipe pressure rating balances lightweight design with robustness, achieving up to 620 psi in 4" configurations.

| Nominal Size | Sch 10 Pressure (psi) | Sch 80 OD (mm) | 1" Pipe Thickness (mm) | Material Grade |

|---|---|---|---|---|

| 1" | 1,200 | 33.4 | 2.41 | 304/316L |

| 2" | 980 | 60.3 | 3.02 | 316Ti/310S |

| 3" | 750 | 88.9 | 3.68 | 321/410 |

| 4" | 620 | 114.3 | 4.78 | 2205 Duplex |

| 6" | 480 | 168.3 | 6.55 | 304L/441 |

Streamlined Global Distribution

Packed in 60x40x40 cm wooden crates (1,000 kg gross weight), these tubes ensure seaworthy protection for intercontinental transit. Whether deploying 120 mesh polished surfaces for food-grade compliance or decoiled strips for automated manufacturing, the 30%TT + 70% balance terms simplify bulk procurement. Thermal stability meets medical autoclave requirements, while schedule 80 variants tackle hydraulic fracturing – a fusion of precision and industrial grit.