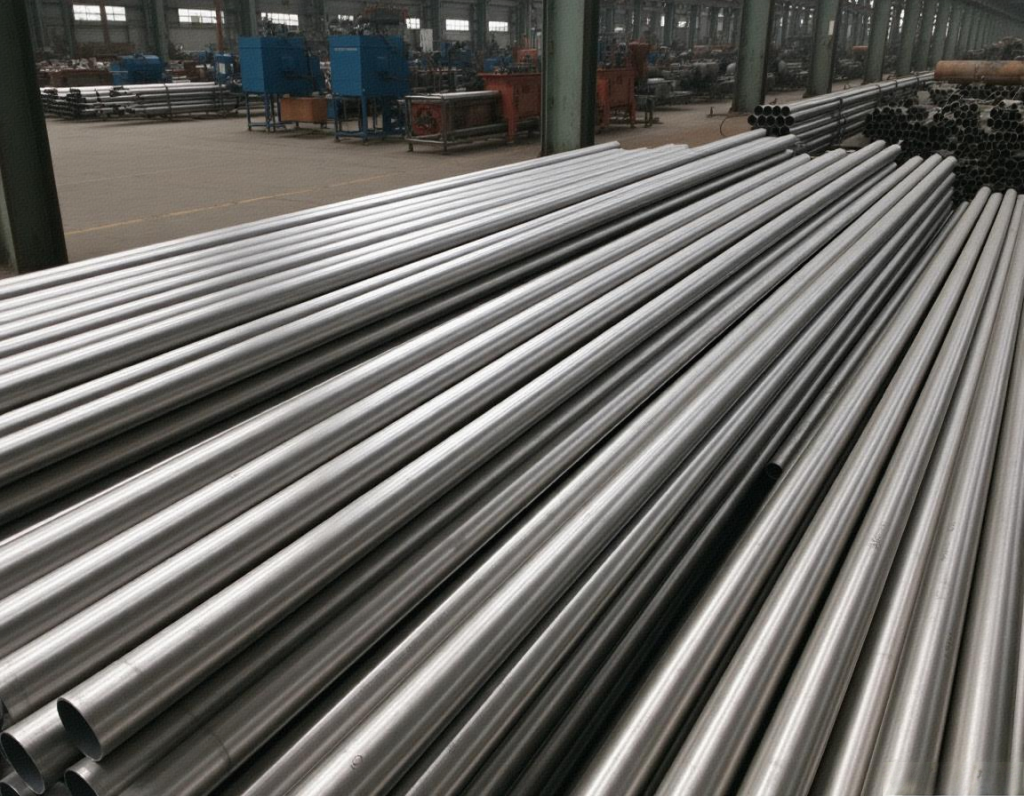

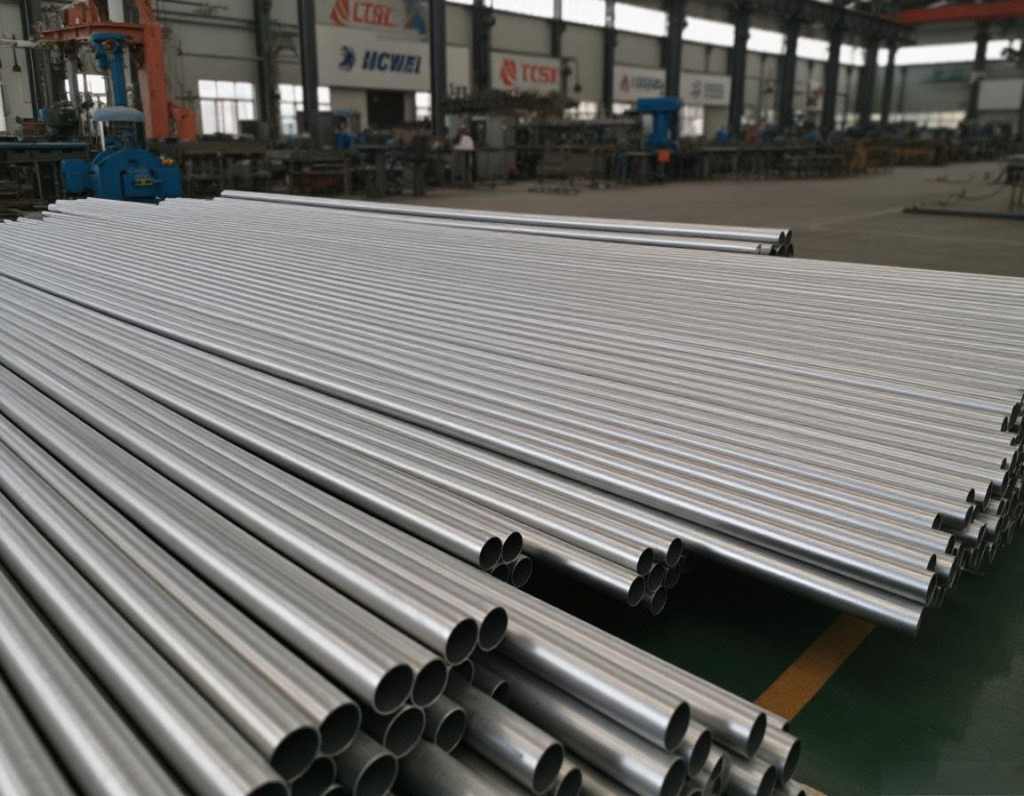

Industrial-Grade Seamless Steel Conduits | Bulk Inventory Mirror-Finished Corrosion-Defying Piping Solutions

Industrial-Grade Seamless Steel Conduits | Bulk Inventory Mirror-Finished Corrosion-Defying Piping Solutions

Contact form

Precision-Engineered Tubing Solutions for Demanding Environments

Crafted to meet ASTM standards with 300 series composition, these stainless steel tubes combine **±0.1%-0.3% dimensional accuracy** and 2B surface finish for seamless integration into chemical processing, medical equipment, or structural frameworks. Available in 1mm–100mm diameters, the 304/316L/321 alloys deliver strong corrosion resistance even under extreme thermal stress. Customization options span bending, laser cutting, and punching, supported by rapid 7-day delivery and flexible 30%TT + 70% balance terms.

Durability Meets Versatility

From schedule 5 stainless steel pipe dimensions ideal for low-pressure hydraulics to schedule 80 stainless steel pipe dimensions built for industrial abrasion, these hollow profiles adapt across pressure thresholds. The schedule 10 stainless steel pipe dimensions strike a balance between weight savings and structural integrity, perfect for architectural cladding.

| Nominal Size | Sch 5 Wall (mm) | Sch 10 OD (mm) | Sch 80 Thickness (mm) | Pressure Rating (psi) |

|---|---|---|---|---|

| 1" | 1.65 | 33.4 | 4.55 | 1,200 |

| 2" | 2.11 | 60.3 | 5.54 | 980 |

| 3" | 2.87 | 88.9 | 7.62 | 750 |

| 4" | 3.23 | 114.3 | 8.56 | 620 |

| 6" | 4.19 | 168.3 | 10.97 | 480 |

Optimized Logistics for Global Procurement

Packed in 60x40x40 cm seaworthy crates with 1-ton MOQ flexibility, these tubes streamline international supply chains. Whether specifying 120 mesh polished surfaces for food-grade applications or decoiled coils for automated assembly, the welding-friendly material properties reduce onsite fabrication costs. Thermal stability meets medical sterilization demands, while 2205 duplex alloys tackle coastal corrosion—proof that precision needn’t sacrifice practicality.