1

/

of

6

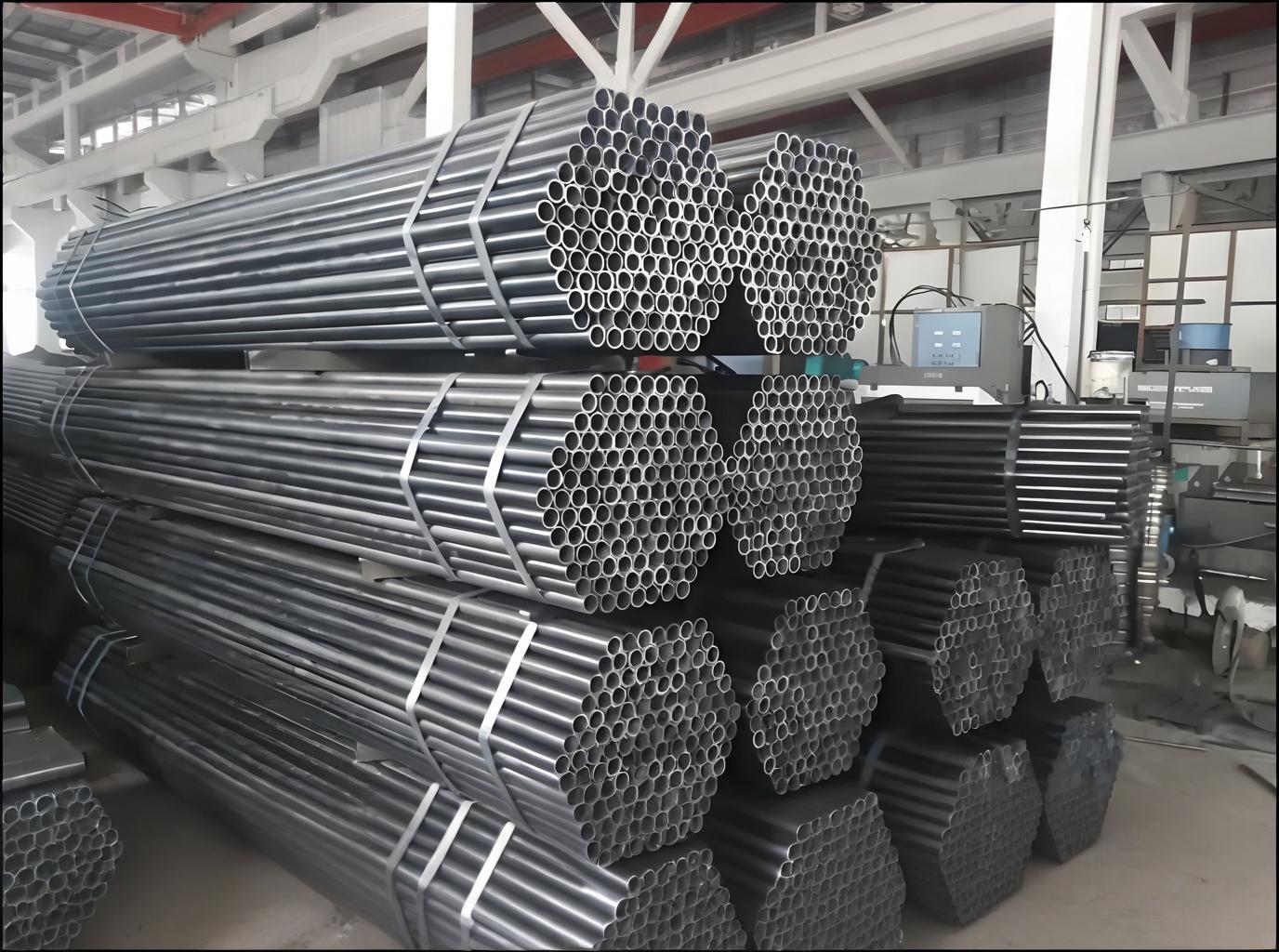

High-Strength 316L Stainless Steel Seamless Pipes Supplier | ASTM Certified 304/2205 Alloy Pipes | Wholesale Inventory

High-Strength 316L Stainless Steel Seamless Pipes Supplier | ASTM Certified 304/2205 Alloy Pipes | Wholesale Inventory

Contact form

Cutting Stainless Steel Pipe: Tools and Techniques

For precision cutting stainless steel pipe, specialized tools like pipe cutter stainless steel are essential. Our seamless stainless steel tubes are designed for clean cuts with minimal burring, ensuring structural integrity. Below are key specifications for efficient processing:

| Property | Specification |

|---|---|

| Diameter Range | 1mm – 100mm |

| Material | 304/304L/316L/321/310S/2205 |

| Tolerance | ±0.1% – 0.3% |

| Surface Finish | 2B (120 Mesh) |

| Applications | Construction, Chemical, Medical |

How to Cut a Stainless Steel Pipe

- Secure the Pipe: Use a vise to prevent slippage.

- Mark the Cut: Measure and mark with a carbide scribe.

- Choose the Tool: Opt for a pipe cutter stainless steel for round pipes or an angle grinder for thick walls.

- Execute the Cut: Apply steady pressure and rotate the cutter gradually.

- Deburr Edges: Smooth edges with a file or sandpaper to prevent corrosion risks.

Pipe Cutter Stainless Steel: Best Practices

- Blade Type: Tungsten carbide blades ensure durability when cutting stainless steel pipe.

- Lubrication: Use cutting oil to reduce heat and extend blade life.

- Speed Control: Avoid overheating by maintaining moderate RPM.

- Post-Cut Care: Clean metal shavings immediately to maintain the 2B surface finish.