1

/

of

5

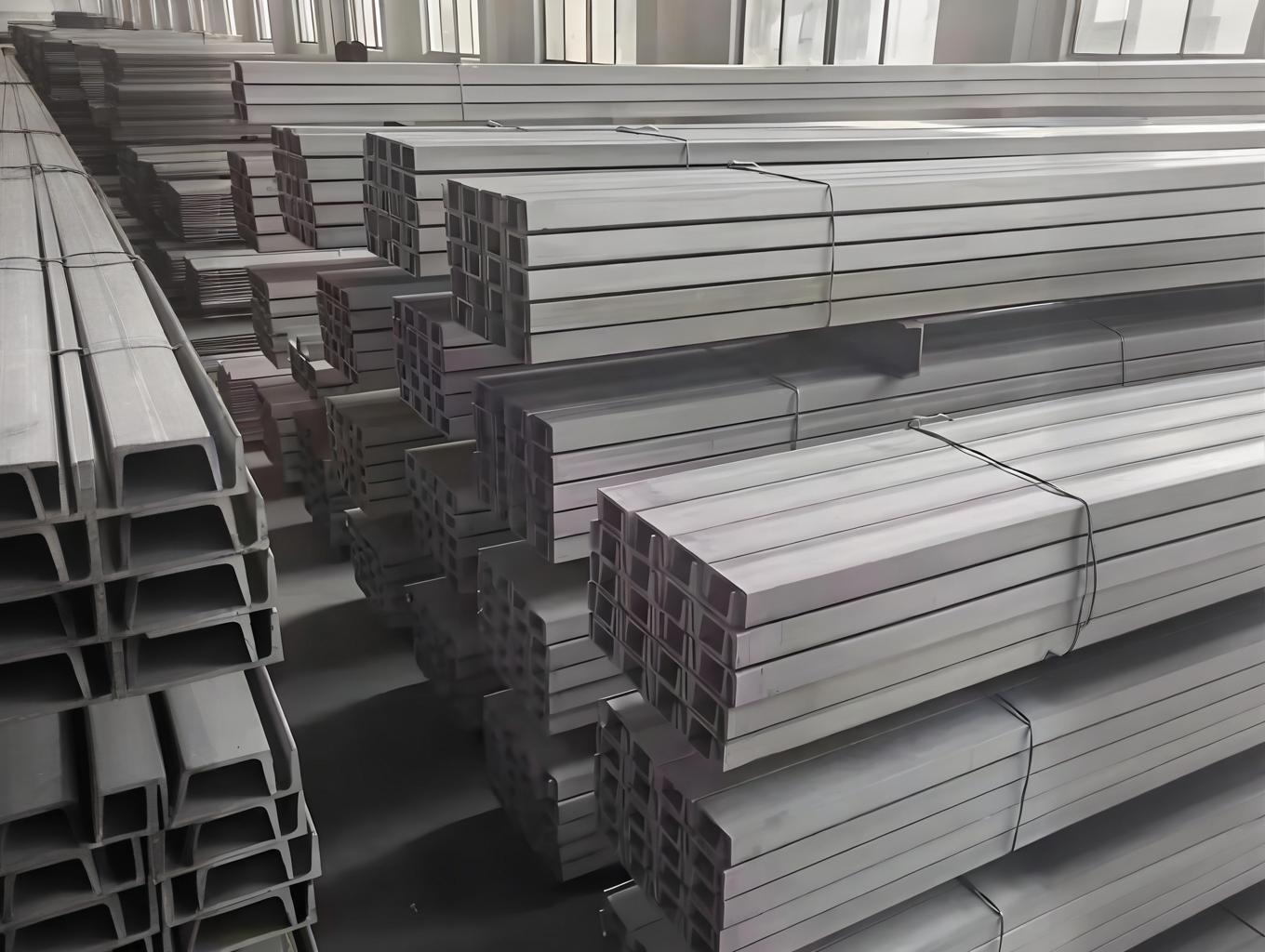

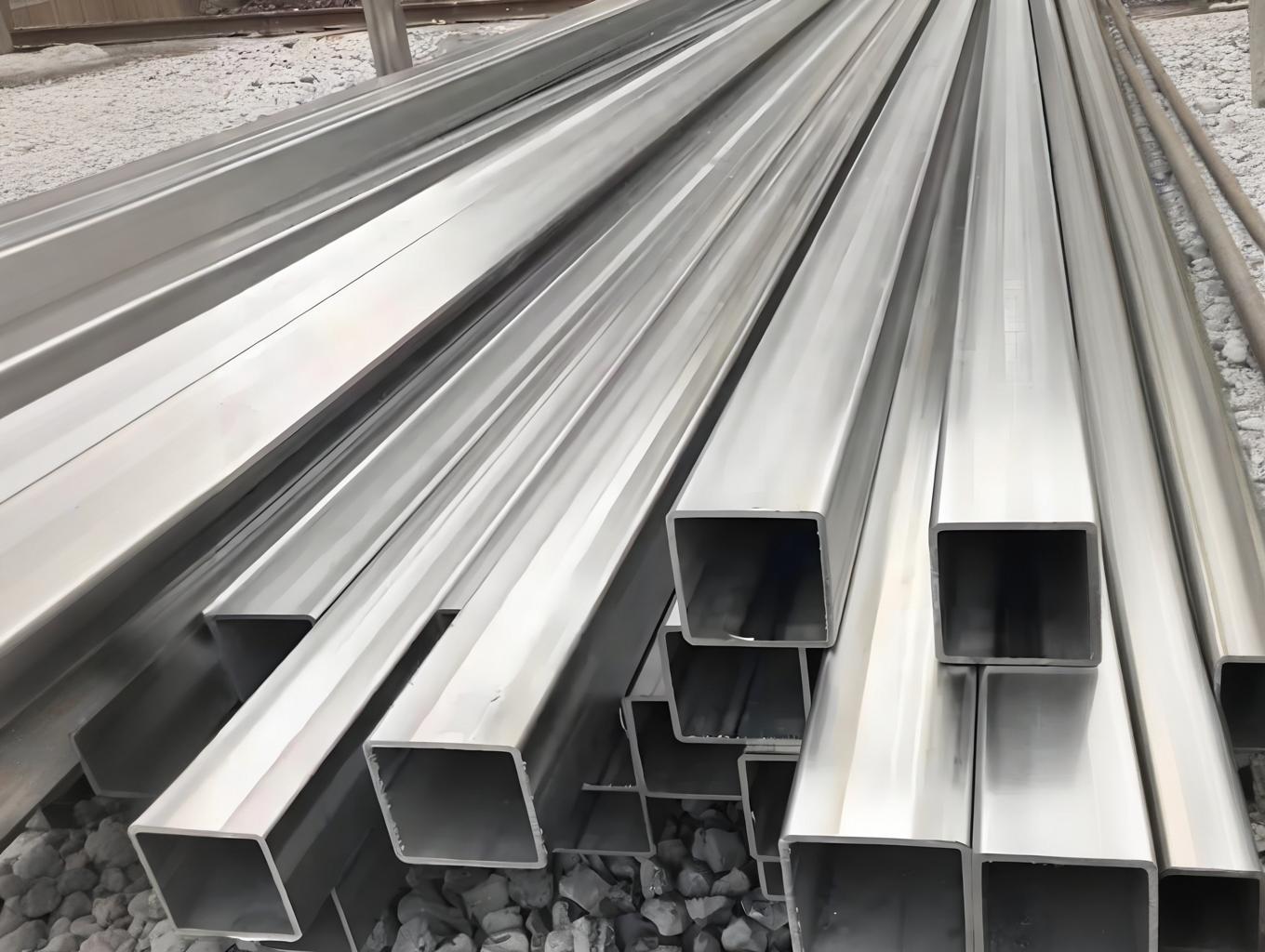

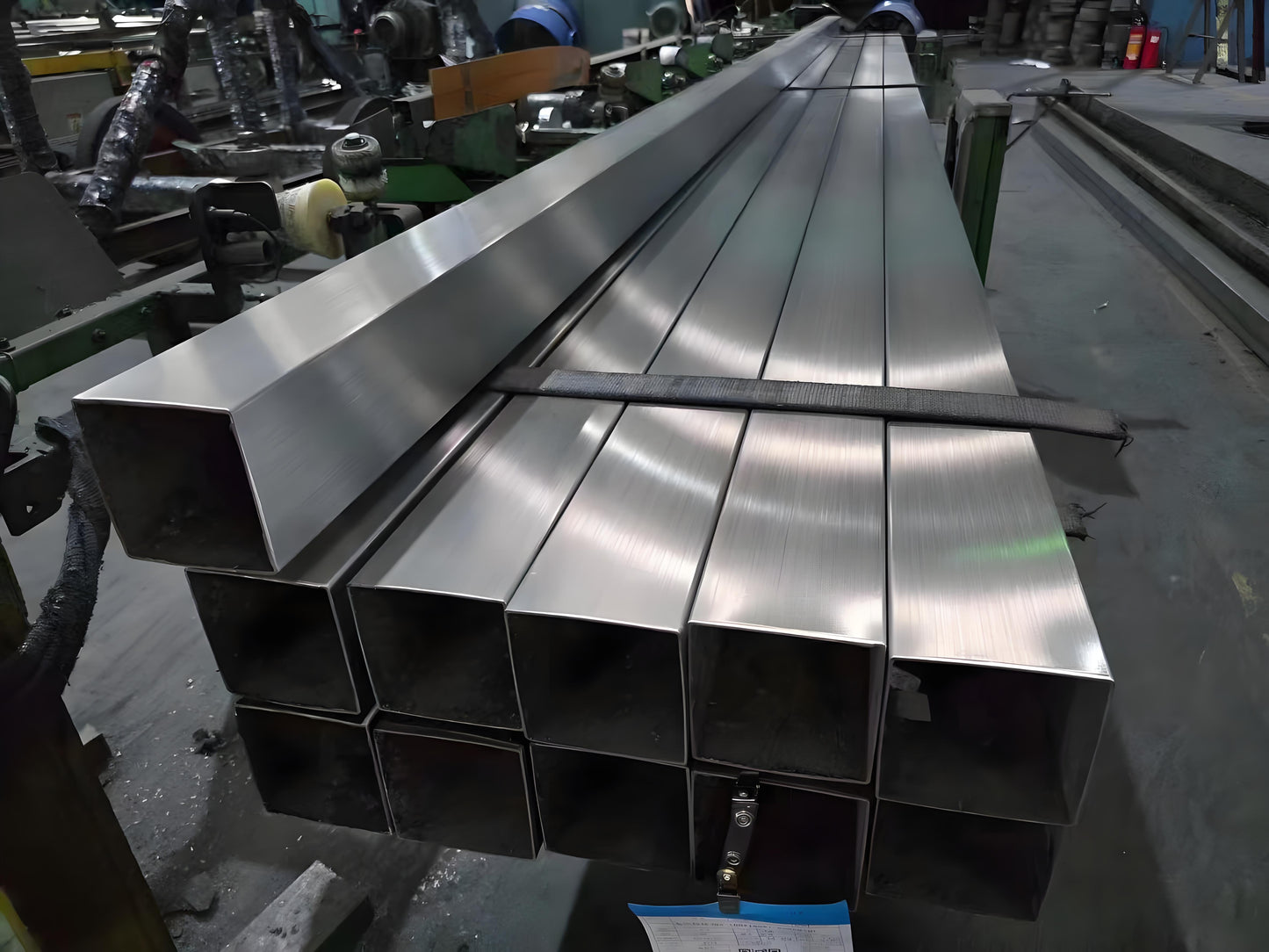

Heavy-Gauge Hot Rolled 316L Stainless Tube | ASTM-Certified Structural Square Pipes 3-120mm Thickness

Heavy-Gauge Hot Rolled 316L Stainless Tube | ASTM-Certified Structural Square Pipes 3-120mm Thickness

Contact form

High-Performance Stainless Steel Structural Tubing

Seamless ASTM-certified square/rectangular tubing crafted from 300-series alloys (Grades 304/316L), engineered for demanding gas systems and construction frameworks with precision tolerances (±0.1%-0.3%) and industrial-grade durability.

Technical Specifications

- Material Composition:

- 304L: Cr 18-20%, Ni 8-10.5%

- 316L: Cr 16-18%, Ni 10-14%, Mo 2-3%

- Surface Quality: 120-grit polished finish (Ra ≤3.2μm)

- Mechanical Properties:

- Yield Strength: 304L ≥170MPa | 316L ≥220MPa

- Pitting Resistance (PREN): 304L=19.5 | 316L=26.8

Key Advantages

◆ Dual Manufacturing Processes:

- Hot-Rolled: 3-120mm thickness (ASTM A312 compliant)

- Cold-Rolled: 0.5-3mm precision (±0.05mm flatness)

◆ Seamless Integrity: Eliminates weld corrosion risks in gas systems

◆ Certified Performance: - 1,500+ hrs salt spray resistance (ASTM B117)

- Temperature range: -40°C to 850°C

Processing Services

[✓] CNC Rotary Bending (180° precision)

[✓] Laser Micro-Cutting (±0.2mm kerf accuracy)

[✓] ASME IX-Certified Welding

[✓] Hydroforming for complex geometries

Logistics & Compliance

- Packaging: Triple-layer seaworthy crates (60×40×40cm)

- VCI anti-corrosion paper

- 2mm PE waterproof coating

- Steel-reinforced wooden frame

- Delivery: 15-21 days for custom lengths (MOQ 1 ton)

- Standards:

- ASTM A312/A789 (Pressure Systems)

- NACE MR0175 (Sour Gas Environments)

- EN 10204 3.1 Material Certification

Applications

✔️ High-pressure natural gas distribution

✔️ Coastal infrastructure reinforcement

✔️ Chemical plant structural supports

✔️ Architectural load-bearing elements

Value-Added Services

- Full material traceability with heat numbers

- 3D CAD file conversion (STEP/IGES formats)

- Third-party inspection coordination