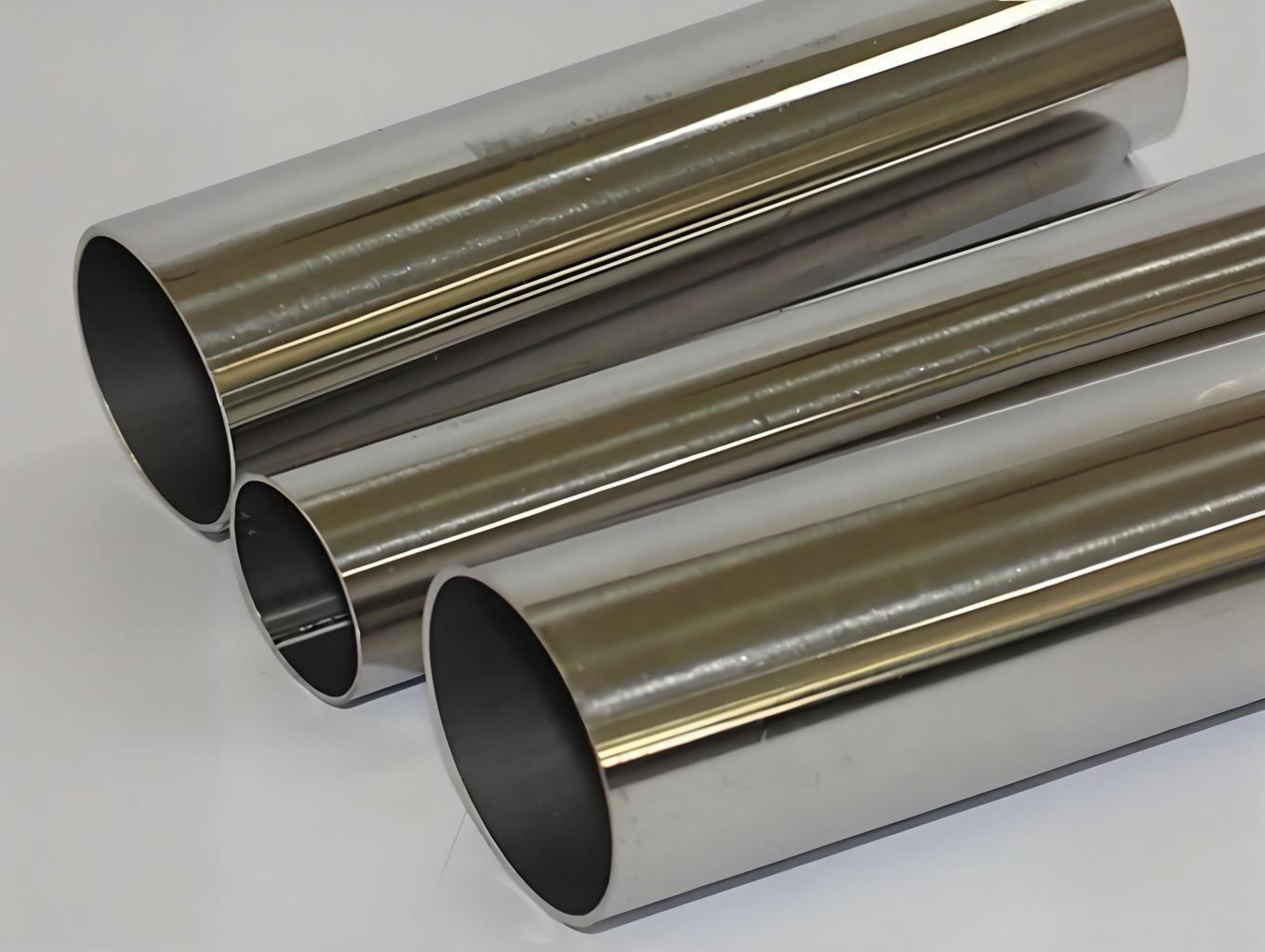

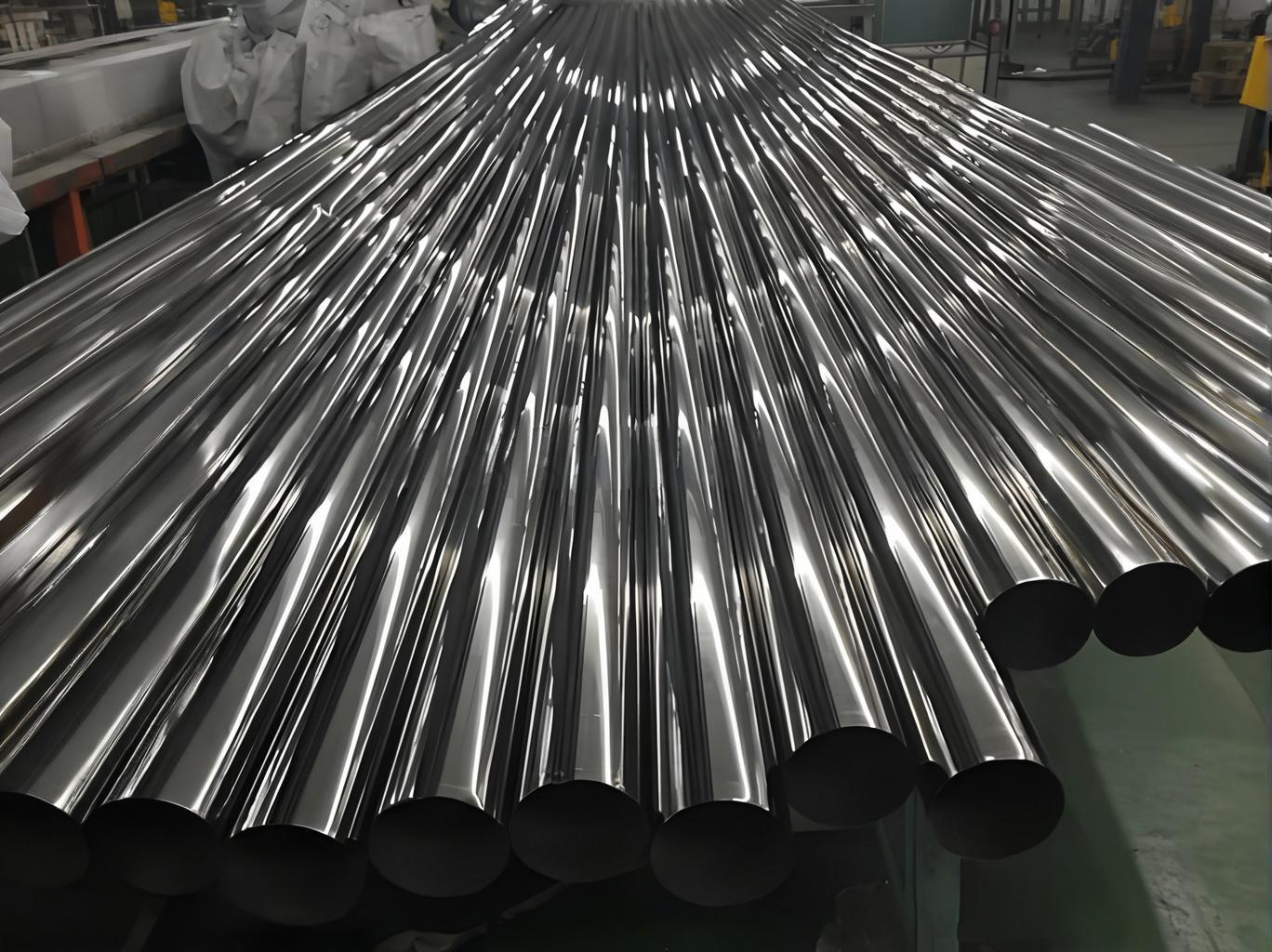

DN32 ASTM 304/316L/2205 Seamless Pipe | High-Temperature Resistant, Precision-Cut Industrial Tubing

DN32 ASTM 304/316L/2205 Seamless Pipe | High-Temperature Resistant, Precision-Cut Industrial Tubing

Contact form

Unrivaled Pressure Integrity for Demanding Systems

When 2,000 PSI steam lines demand fail-safe performance, stainless steel schedule 40 pipe rises to the challenge. Cold-drawn from 316L or duplex 2205 alloys, these tubes laugh off chloride-rich brine in desalination plants while maintaining ±0.2% wall uniformity. Picture them in geothermal boreholes—310S-grade segments endure 400°C thermal cycling without scaling, their 2B surface finish (Ra ≤0.6μm) minimizing turbulent flow. For breweries needing CIP-compliant sanitation, electropolished stainless steel seamless pipe in 304L glides through caustic soda flushes, 120-mesh interiors resisting biofilm colonization.

Seamless Engineering for Zero-Compromise Applications

Forged under 10,000-ton hydraulic presses, stainless steel seamless pipe eliminates weak points that plague welded alternatives. Aerospace hydraulics leverage 321-grade tubes’ titanium-stabilized resistance to sensitization, while 441-grade coils transform into seismic bracing for skyscrapers via CNC bending. Threading? Not an obstacle: stainless steel threaded pipe fittings emerge from Swiss-style lathes with NPT/GOST profiles cut to 0.01mm precision. For ultrahigh-vacuum chambers, TIG-welded 316Ti manifolds maintain 10^-9 mbar integrity—every micron scrutinized by helium leak detectors.

Modular Connectivity for Global Infrastructure

Assemble labyrinthine networks with surgical precision: stainless steel threaded pipe fittings in 410S alloy bridge offshore wind farms to onshore substations, their PTFE-taped joints impervious to North Sea squalls. Decoiled 304N strips become pharmaceutical cleanroom grids, plasma-cut and deburred for orbital welding. Need DN50 stainless steel schedule 40 pipe for biodiesel transport? 7-day shipments arrive in 60x40x40cm armored crates, MOQs as lean as 1 ton. Payment terms (30% TT advance) keep projects fluid; mill certs and 3D bend diagrams nestle beside RFID-tagged stainless steel seamless pipe batches—because global ambitions demand traceable perfection.