Industrial-Grade Seamless Tubes Engineered for Demanding Environments – Corrosion-Defying Durability & Cost-Optimized Sizing

Industrial-Grade Seamless Tubes Engineered for Demanding Environments – Corrosion-Defying Durability & Cost-Optimized Sizing

Contact form

Precision-Engineered Stainless Steel Conduits for Industrial Applications

Crafted to meet rigorous ASTM 300 Series standards, our seamless 2 sch 40 stainless steel pipe solutions combine ±0.1%-0.3% dimensional accuracy with 2B surface finishes (120 mesh) for flawless integration into high-stress systems. Available in diameters from 1mm to 100mm, these tubes excel in thermal stability and corrosion resistance, ideal for chemical processing and medical infrastructure.

Unmatched Versatility in Critical Environments

The 2 schedule 40 stainless steel pipe series supports custom bending, welding, and cutting, tailored for projects requiring 301L to 316Ti alloys. With a 7-day turnaround and seaworthy wooden packaging, these pipes ensure structural integrity under extreme conditions while maintaining cost-efficiency.

| Specification | Details |

|---|---|

| ASTM Standard | 300 Series |

| Diameter Range | 1mm~100mm |

| Surface Finish | 2B (120 Mesh) |

| Mechanical Properties | ±0.1%-0.3% Dimensional Tolerance |

| Available Alloys | 304/304L/316L/321/310S/2205 |

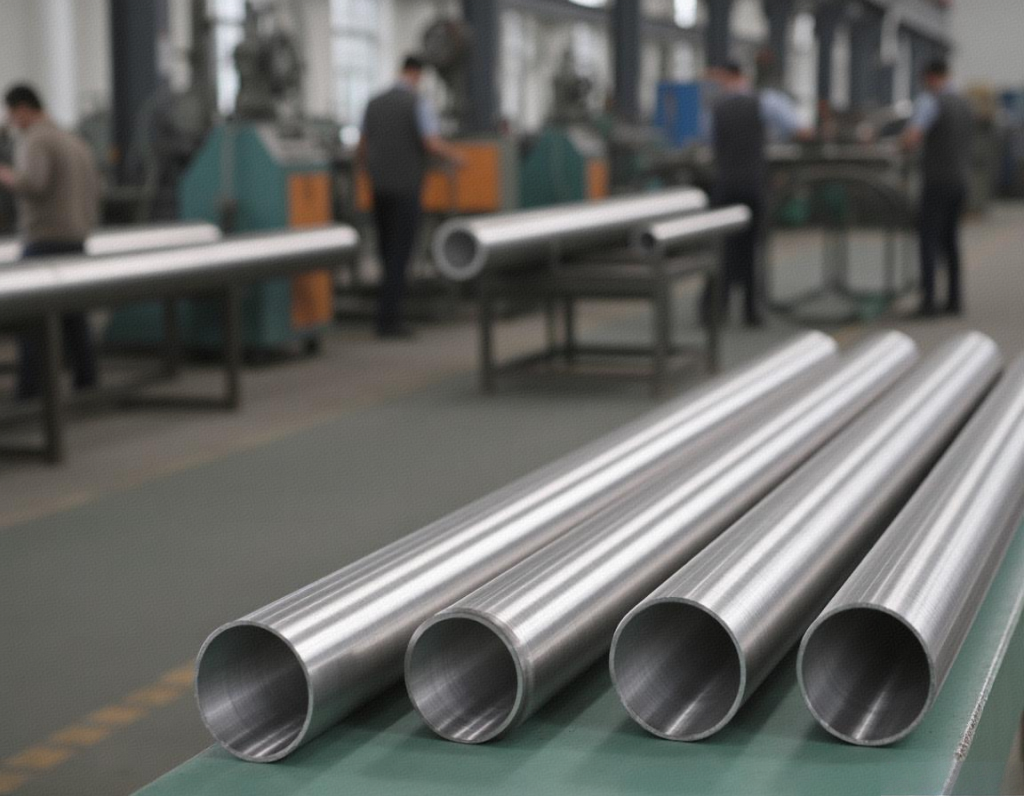

Optimized Performance for Complex Fabrication

Engineered for seamless decoiling and punching, the 2 stainless steel pipe schedule 40 range delivers strong corrosion resistance across 410S to 441 grades. With a 1-ton MOQ and flexible 30%TT+70%TT payment terms, these precision tubes streamline construction timelines without compromising on military-grade durability or thermal expansion control.