1

/

of

5

ASME SA213 Certified 304/316L Seamless Tubes | High-Temp Chemical Plant Piping Systems

ASME SA213 Certified 304/316L Seamless Tubes | High-Temp Chemical Plant Piping Systems

Contact form

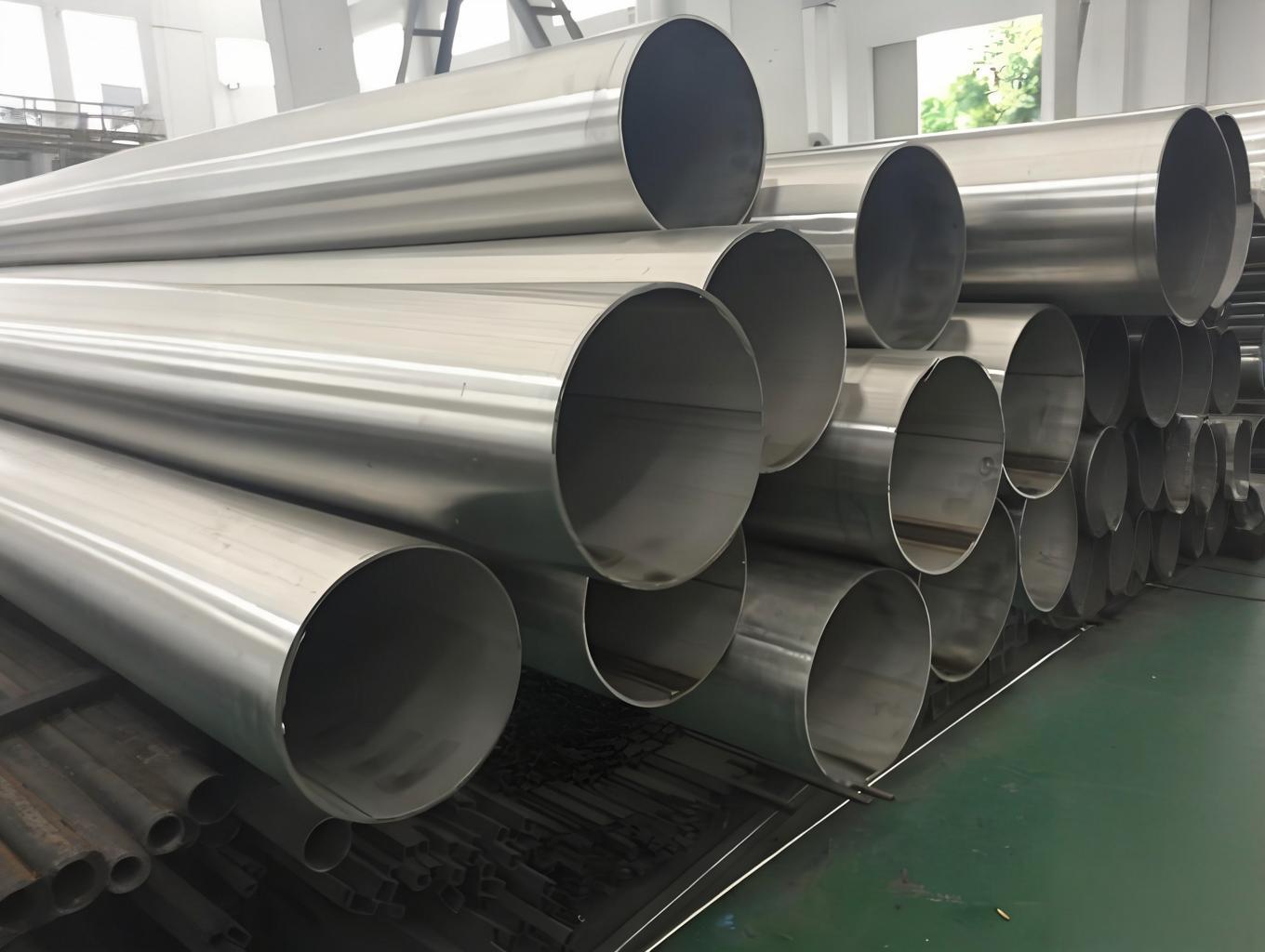

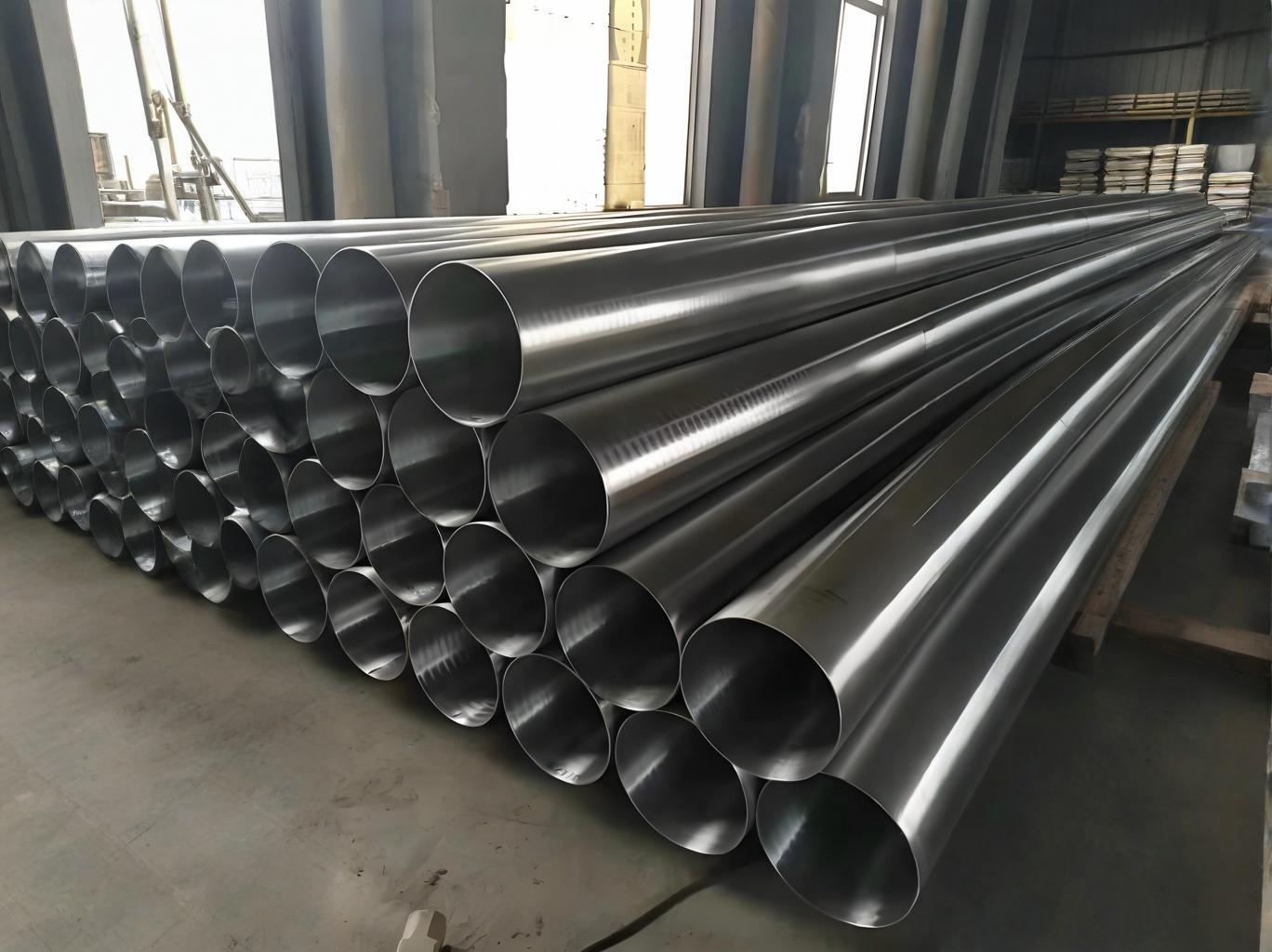

Ultra-Precision Stainless Steel Seamless Tubing for Critical Infrastructure

ASME-Certified Pipes with Multi-Industry Compliance & Enhanced Material Properties

Technical Specifications:

- Material Grades: 301L, 304N, 316Ti, 316L, 321, 310S, 2205 duplex + 400 series variants

- Dimensional Accuracy: ±0.1%-0.3% OD tolerance (1-100mm diameter range)

- Surface Integrity: 2B cold-rolled finish with 120-grit mirror polish (Ra ≤0.35μm)

- Certifications: NACE MR0175, ASME BPE-2023, EN 10204 3.2

Key Performance Advantages:

✓ Chloride Stress Corrosion Resistance (Passes ASTM G48 Method D at 25% NaCl)

✓ Accelerated Lead Times: Full-process manufacturing within 7 working days

✓ Value-Added Fabrication: Orbital TIG welding, CNC cold drawing, laser micro-drilling

✓ Multi-Sector Applications: Nuclear reactor coolant lines, bio-pharma CIP systems, subsea umbilicals

Enhanced Engineering Parameters:

- Pitting Resistance Equivalent (PREN): 304(19.8) | 316L(28.3) | 2205(36.7)

- Temperature Range: -269°C (liquid helium) to 700°C cyclic operation

- Hydrostatic Pressure: Tested to 2.5x working pressure (ASME B31.3 compliant)

- Passivation Standard: Electropolished per ASTM A967 Citric Acid method

Order Parameters:

- Flexible Procurement: 1 MT minimum order quantity with JIT scheduling

- Secure Transactions: LC/SBLC payment options with escrow protection

- Global Logistics: IPPC-certified crates (60×40×40cm; 1MT capacity)

Quality Assurance Protocol:

- Triple verification: PMI/XRF analysis, eddy current testing, helium mass spec leak detection

- Full material traceability from melt to final product

- Salt spray corrosion testing exceeding 10,000 hours (ASTM B117)