1

/

of

6

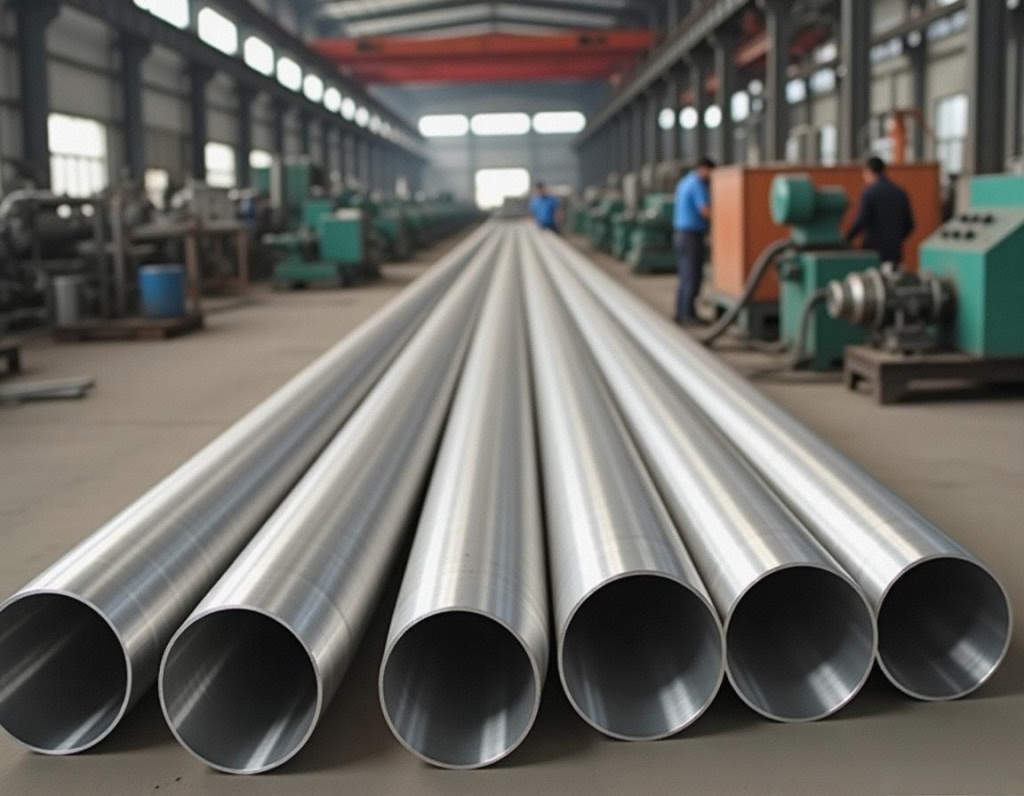

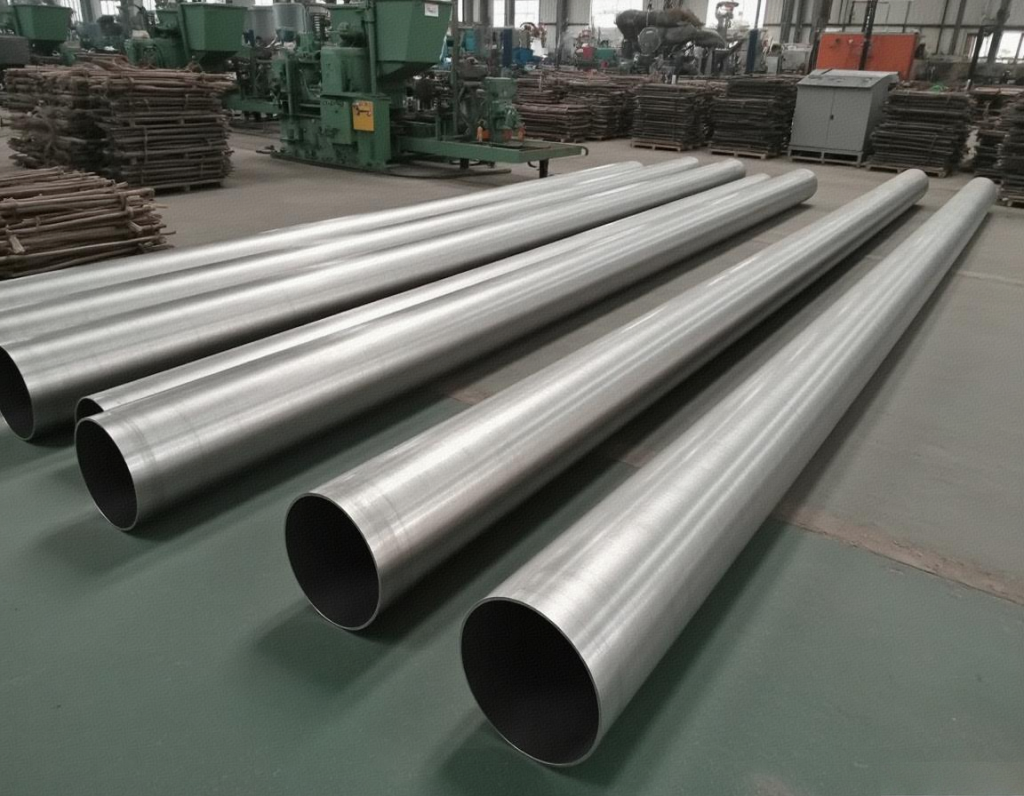

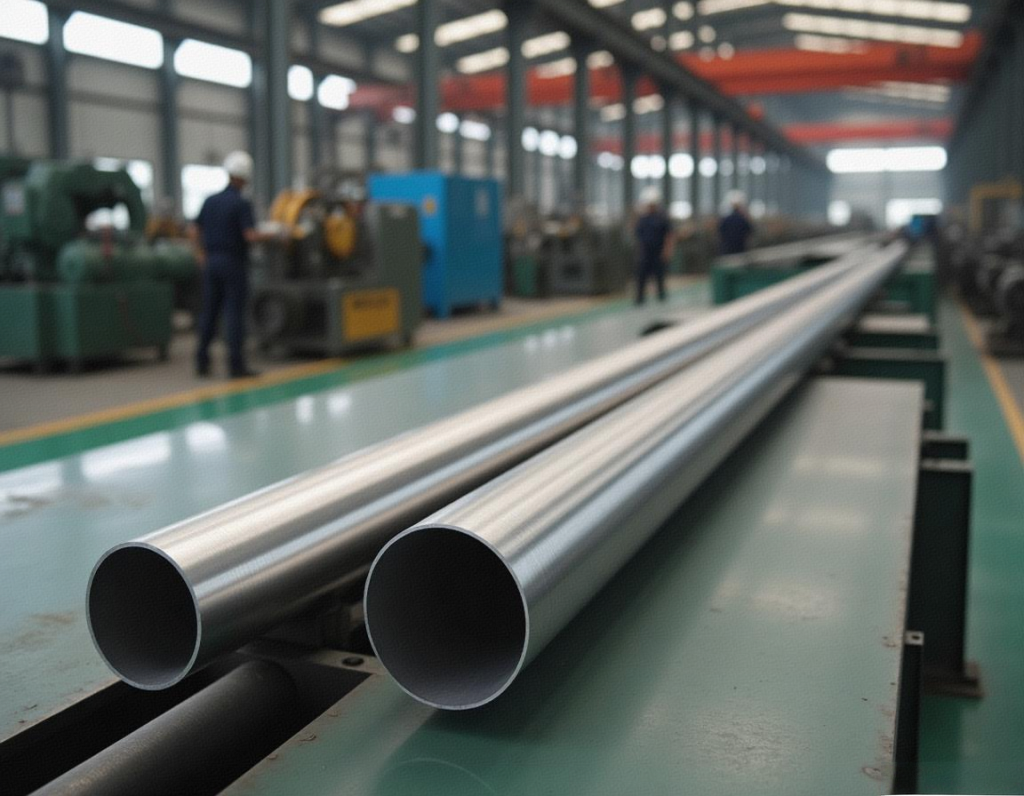

Industrial Seamless Stainless Steel Tubing Cost-Effective SCH40/SCH80 Sizes | 304/316L/2205 Alloys | 7-Day Production Lead Time

Industrial Seamless Stainless Steel Tubing Cost-Effective SCH40/SCH80 Sizes | 304/316L/2205 Alloys | 7-Day Production Lead Time

Contact form

| Material Grade | Diameter Range | Surface Finish | Primary Application | Processing Service |

|---|---|---|---|---|

| 304/304L | 1–50 mm | 2B | Plumbing Systems | Bending, Cutting |

| 316L/316Ti | 20–100 mm | Polished | Chemical Fittings | Welding |

| 310S/321 | Custom | 120 Mesh | High-Temperature Lines | Decoiling |

| 2205 Duplex | 10–80 mm | Pickled | Marine Hardware | Punching |

| 410/410S | 1½"–4" | Hairline | Structural Supports | Custom Fabrication |

Comprehensive pipe schedule chart stainless steel compatibility ensures adherence to ASME B36.19 and EN 10217-7 standards. Tubes are available in pre-cut 6m lengths or custom sizes, with hydrostatic testing up to 6,000 PSI for industrial safety.

Corrosion-resistant polished stainless steel pipe solutions include seamless and welded variants, packaged in seaworthy wooden crates for global logistics. Services include threading, flanging, and precision cutting, with 7-day lead times and flexible payment terms.

Technical Specifications:

- Pipe fittings stainless steel: 1/8"–4" NPT/BSPP threads, 3000 PSI pressure-rated.

- Pipe schedule chart stainless steel: SCH10–SCH160 wall thickness compliance.

- Polished stainless steel pipe: Ra ≤ 0.4μm surface roughness for sanitary applications.

Compliance & Testing:

- Standards: ASTM A312 (welded) / A269 (seamless).

- Surface finishes meet ISO 1302 and ASME B46.1.

- MOQ: 1 ton with 30% TT advance payment.