Cost-Efficient Machining-Grade Conduits | 304/316L/2205 Welded Pipes | ASME-Certified with ±0.2% Wall Tolerance

Cost-Efficient Machining-Grade Conduits | 304/316L/2205 Welded Pipes | ASME-Certified with ±0.2% Wall Tolerance

Contact form

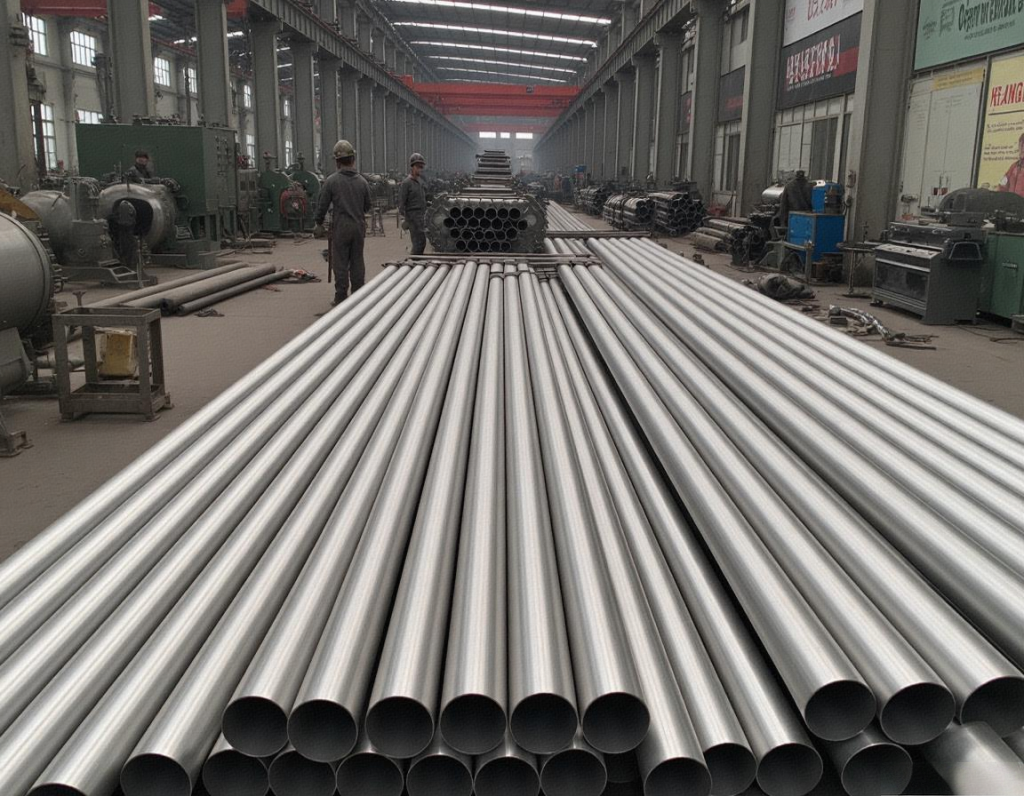

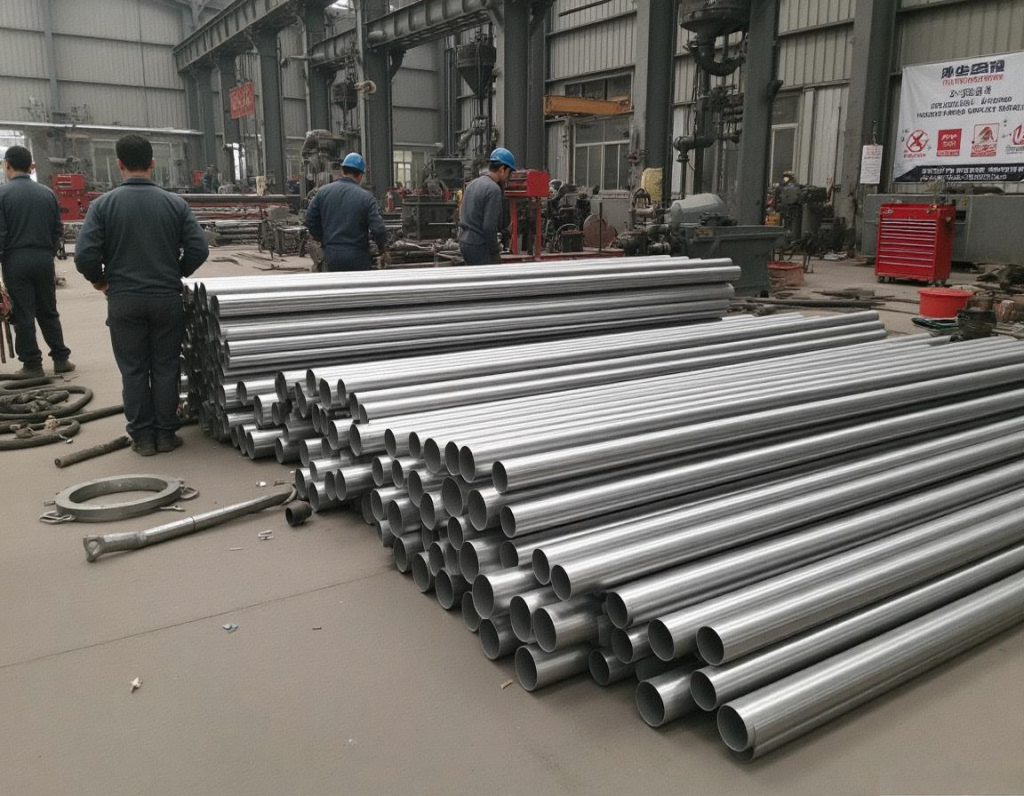

Durable Hydraulic Conduits for Critical Systems

ASTM-certified stainless steel water pipes achieve NSF/ANSI 61 compliance for potable water distribution, featuring 316L alloy with 120-grit polished interiors to prevent biofilm accumulation. These conduits withstand 2,500 PSI hydrostatic pressure, ideal for desalination plant reverse osmosis arrays.

| Performance Benchmark | Technical Specification |

|---|---|

| Cyclic Pressure Testing | 10,000+ cycles at 5x operating PSI |

| Double-Wall Insulation Value | 0.25 W/m·K (600°C ambient) |

| Surface Roughness | 0.4µm Ra (electropolished) |

| Cross-Sectional Tolerance | ±0.15% per ASTM A999 |

| Chloride Stress Threshold | 50,000 ppm in 80°C brine |

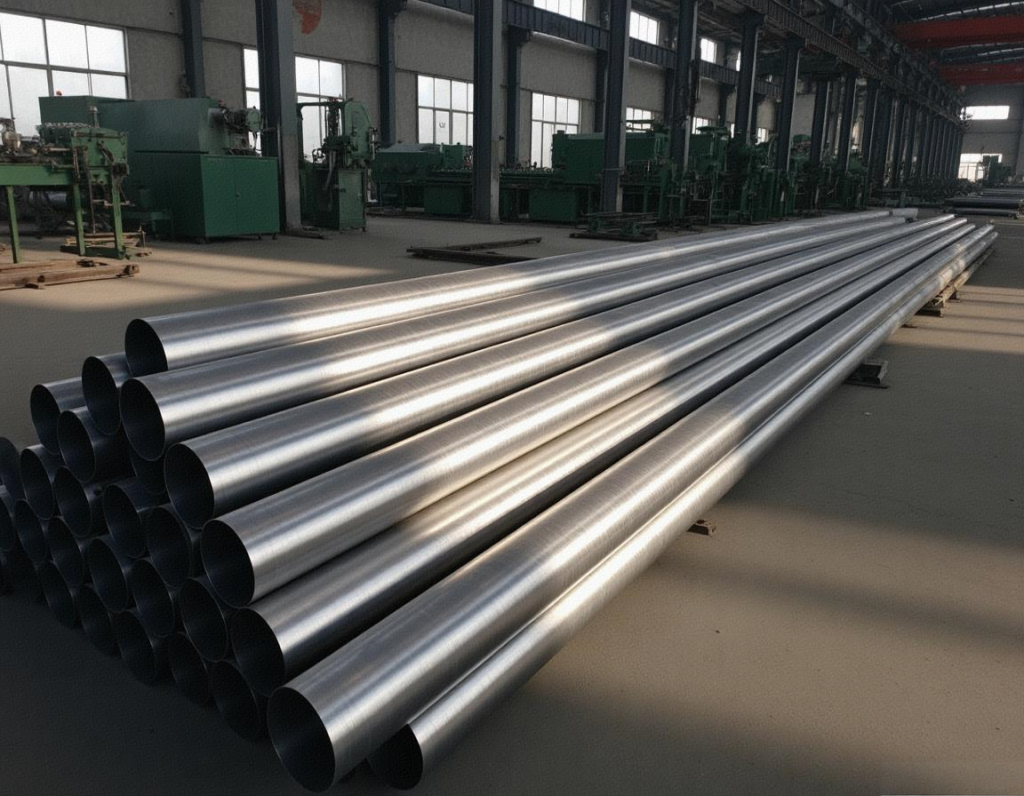

High-Temperature Exhaust Solutions

The stainless steel wood stove pipe double wall configuration reduces external surface temperatures by 60% through argon-filled insulation chambers. 310S alloy variants maintain structural integrity at 950°C continuous exposure, featuring 3D-laser-cut mounting flanges for seamless integration with existing HVAC systems.

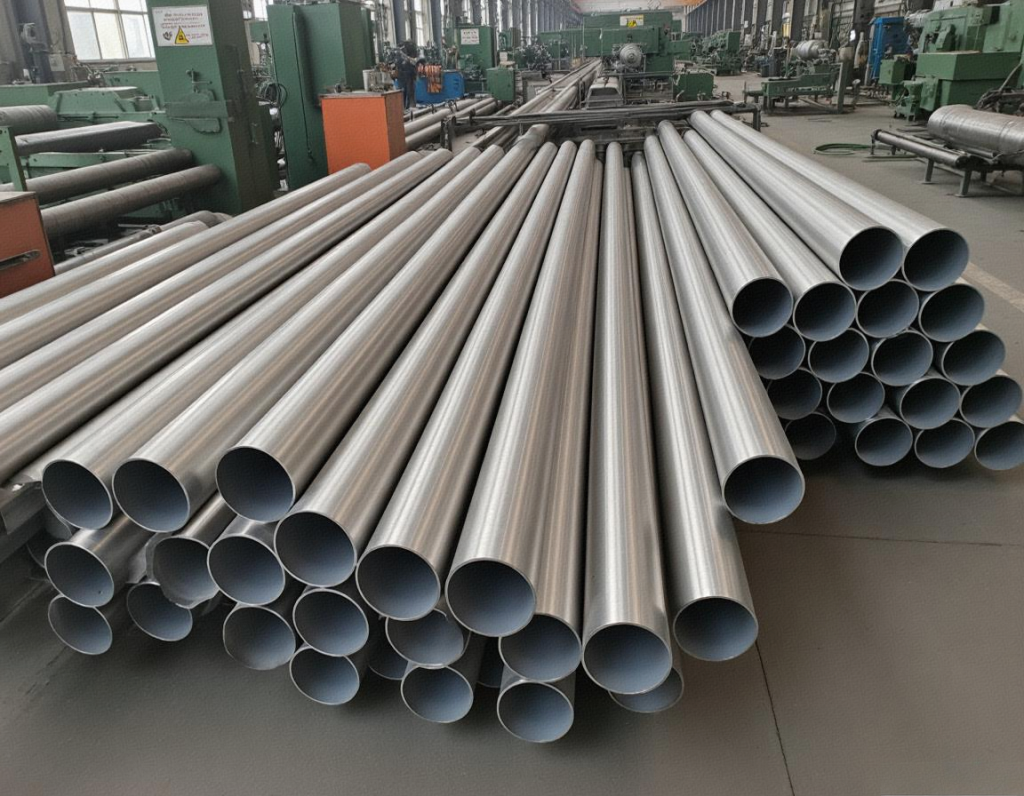

Optimized Structural Connectivity

Precision-engineered stainless steel x pipe junctions enable 360° fluid dynamics optimization in chemical reactor manifolds. CNC-bent 304/316L elbows achieve 0.2mm radius accuracy, paired with ASME B16.9 compatible flanges. Inventory includes 1-100mm diameter stock packaged in anti-corrosion wooden crates with desiccant systems for transoceanic shipments.