Rapid-Deployment Heat Exchanger Tubing | 4mm 316L Welded Pipes | NACE MR0103 Sour Service Compliance

Rapid-Deployment Heat Exchanger Tubing | 4mm 316L Welded Pipes | NACE MR0103 Sour Service Compliance

Contact form

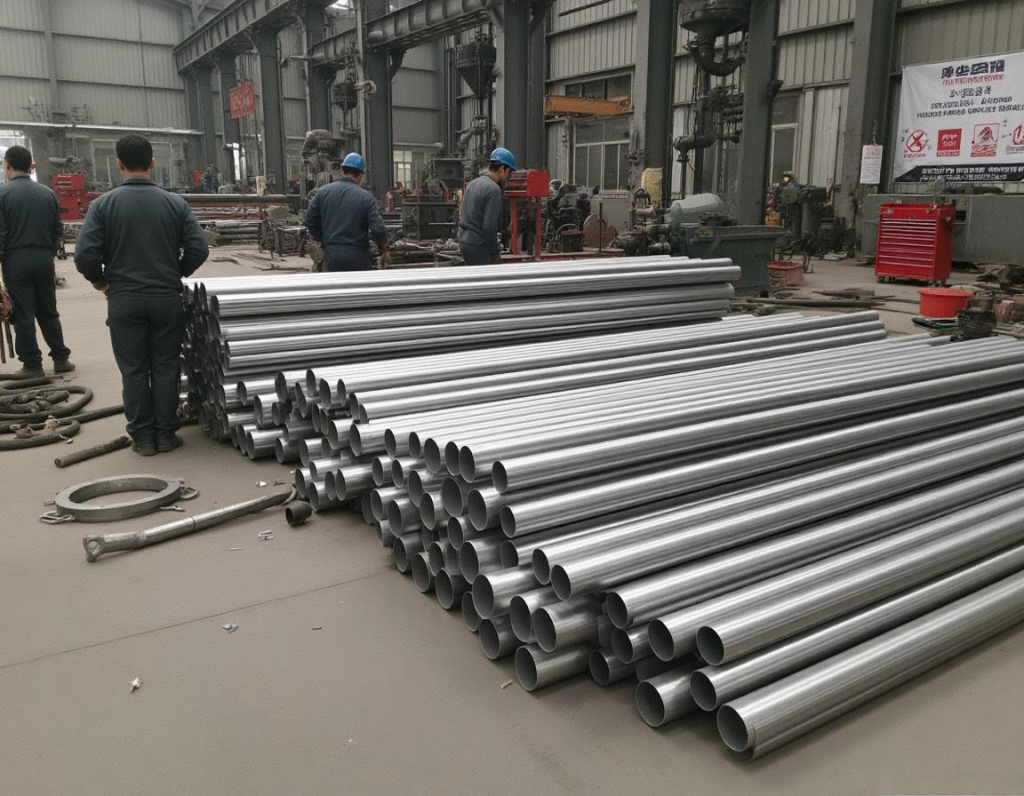

Precision-Crafted High-Pressure Conduits

ASTM-compliant stainless steel pipe tube systems withstand 3,200 PSI at 150°C, featuring 300-series alloys with ±0.2% ovality tolerance for petrochemical cracking units. Mirror-finished 316L variants (120-grit polish) resist chloride-induced stress corrosion in marine exhaust applications, compatible with stainless steel schedule pipe chart SCH10-SCH160 standards.

| Critical Engineering Metric | Technical Specification |

|---|---|

| Hydrostatic Test Pressure | 4.8x operational threshold |

| Interpass Temperature Limit | 150°C max during welding |

| Surface Roughness Post-Polish | 0.6μm Ra (medical-grade) |

| Diameter Range | 6mm-250mm (custom extruded) |

| Pitting Resistance Number | PREN 36 (304L) / PREN 41 (2205) |

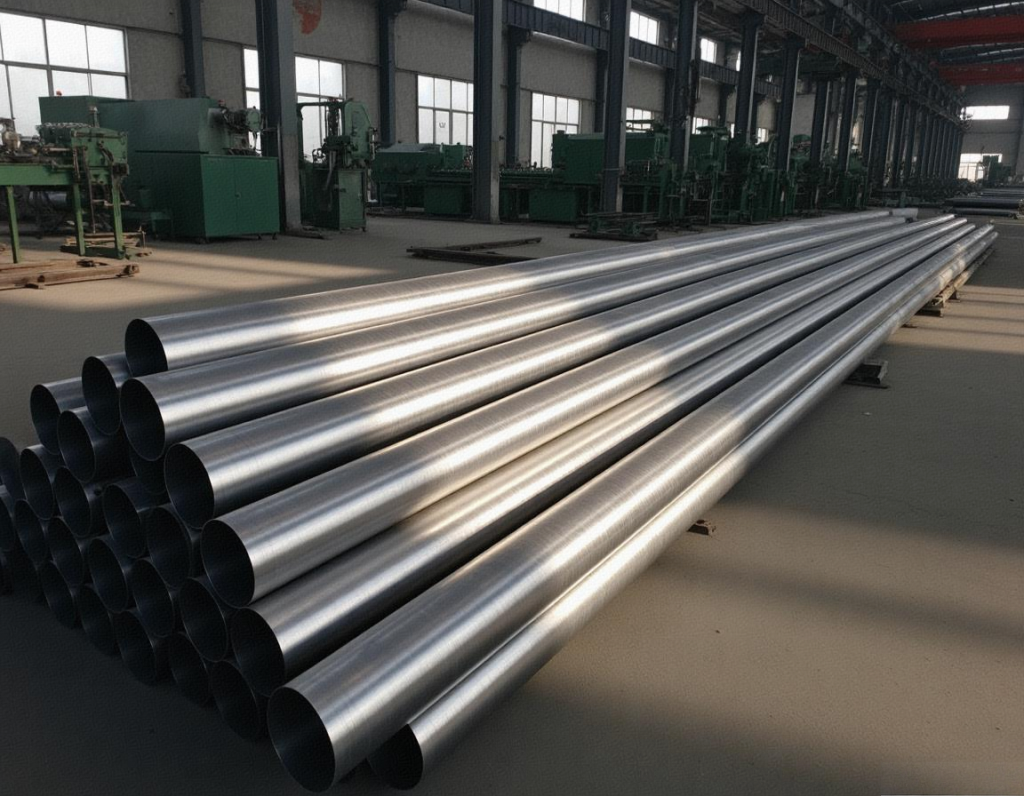

Industrial Fluid Dynamics Solutions

The interactive stainless steel schedule pipe chart enables precise selection of 4mm-12mm wall thicknesses for ASME B31.9 district heating networks. CNC-machined stainless steel stove pipe 6 inch configurations achieve 98% argon-shielded TIG weld purity, ideal for biomass boiler flue systems requiring 850°C continuous operation.

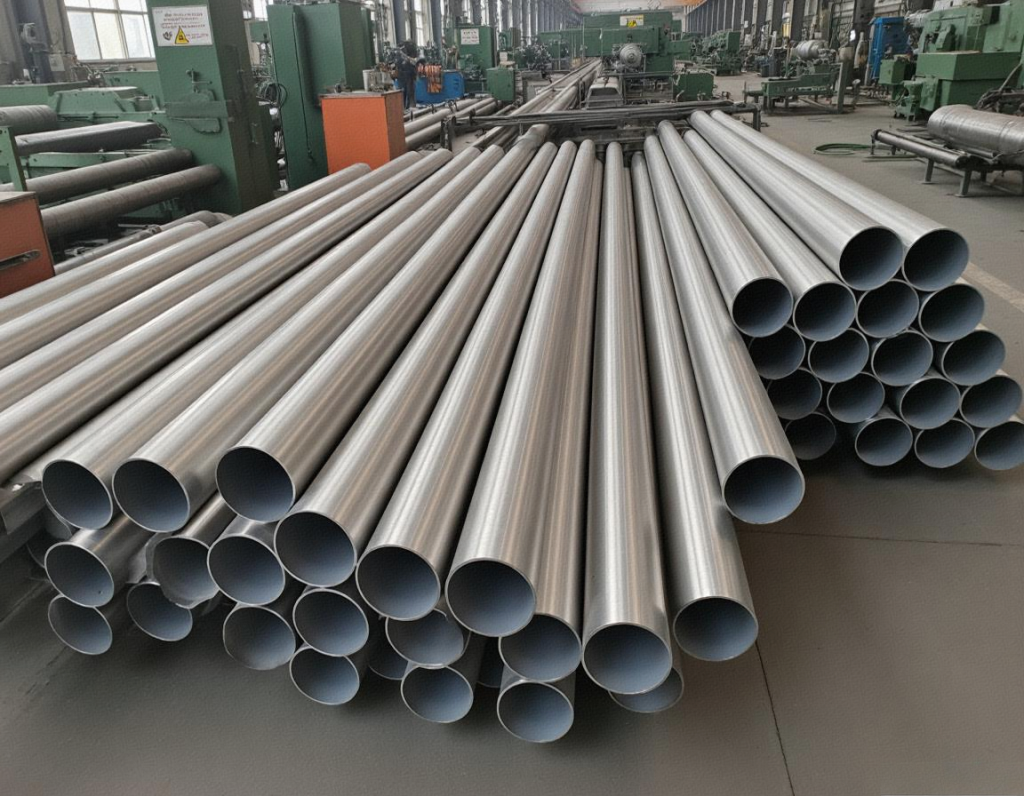

High-Temperature Exhaust Architectures

6-inch stainless steel stove pipe 6 inch assemblies demonstrate 2.3x creep resistance versus standard alloys in foundry exhaust stacks. Hot-dip passivated 310S variants include integrated expansion joints for thermal cycling from -30°C to 900°C. Inventory supports 7-day global shipment in anti-condensation wooden crates with 30/70 payment flexibility.