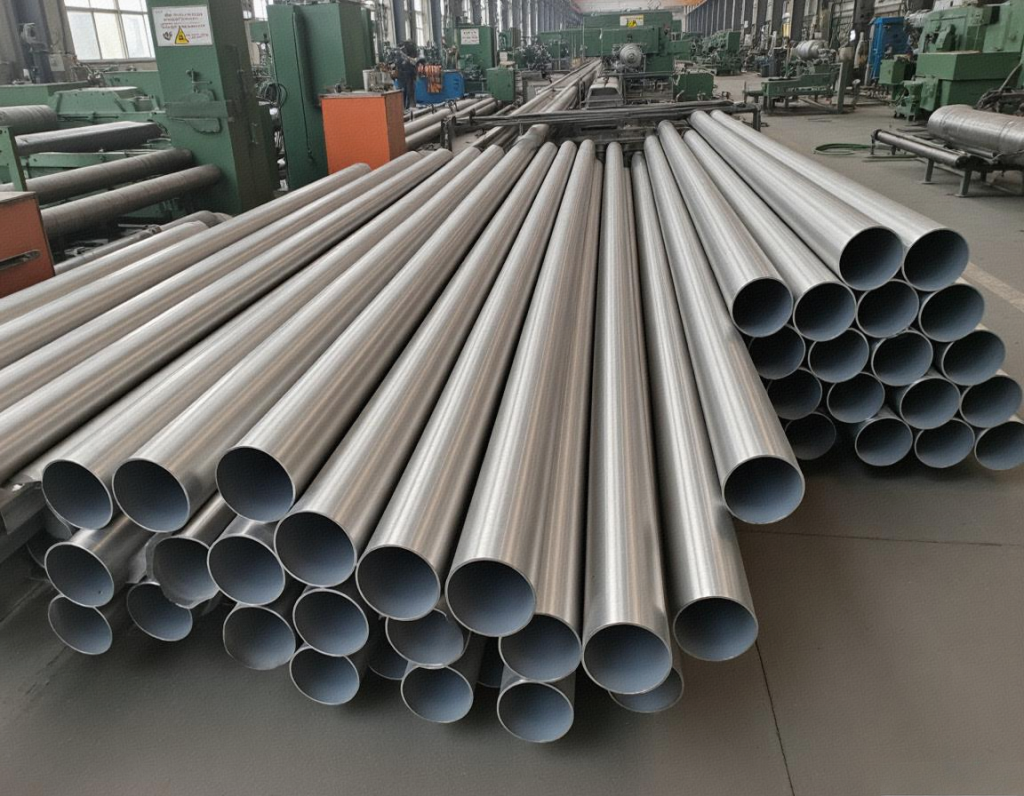

Rapid-Custom Machining Conduits | 304/316L/2205 Stainless Pipes | ASME-Certified with 48hr Prototyping

Rapid-Custom Machining Conduits | 304/316L/2205 Stainless Pipes | ASME-Certified with 48hr Prototyping

Contact form

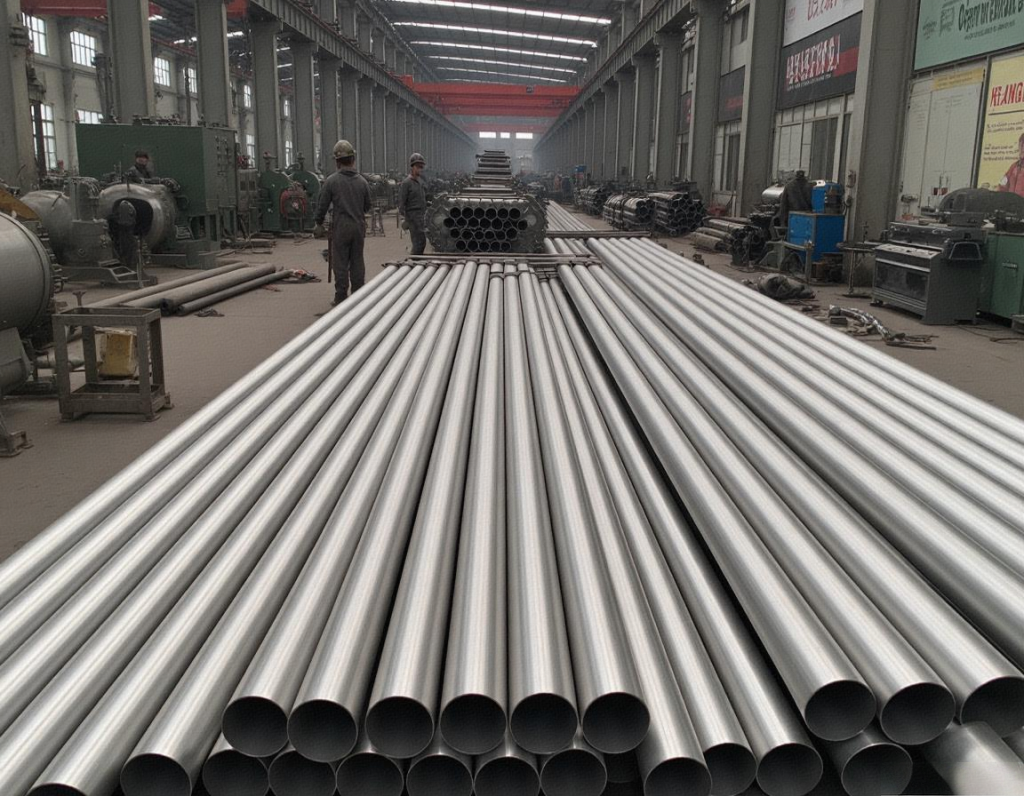

Precision-Engineered Welding Solutions

ASTM-compliant TIG welding stainless steel pipe systems achieve 99.9% argon shielding purity for aerospace-grade butt joints, with 316L variants demonstrating 1,800-hour salt spray resistance. Cold-rolled 304 pipes feature 120-grit polished surfaces ideal for pharmaceutical-grade fluid transfer networks requiring zero biofilm risk.

| Critical Performance Metric | Specification |

|---|---|

| Weld Penetration Consistency | ±0.15mm depth variance |

| Pressure Rating (SCH40) | 2,200 PSI @ 150°C |

| Intergranular Corrosion Test | Pass ASTM A262 Practice E |

| Ovality Tolerance | ≤0.2% of nominal diameter |

| Surface Roughness Post-Weld | 1.2μm Ra (mirror finish) |

Industrial-Grade Dimensional Versatility

The 1 1/2 inch stainless steel pipe configuration withstands 4,500 PSI hydrostatic pressure in chemical processing manifolds, while 1 1/4 stainless steel pipe variants optimize steam distribution in power plant applications. Both sizes accommodate ASME B36.19 specifications with ±0.1% wall thickness consistency.

High-Performance Flow Architectures

Custom-extruded 1 1/2 inch stainless steel pipe assemblies integrate seamless 90° elbows for refinery flare gas systems, paired with NACE MR0175-compliant 2205 duplex alloy. Inventory includes 1-100mm diameter stock in anti-corrosion wooden crates, supporting 7-day global delivery with 30/70 payment flexibility for infrastructure projects.