1mm Precision-Wall Duplex Steel Pipes | 304/316L/2205 Machinable Welding Solutions | Factory-Priced Bulk Stock with ASME Certification

1mm Precision-Wall Duplex Steel Pipes | 304/316L/2205 Machinable Welding Solutions | Factory-Priced Bulk Stock with ASME Certification

Contact form

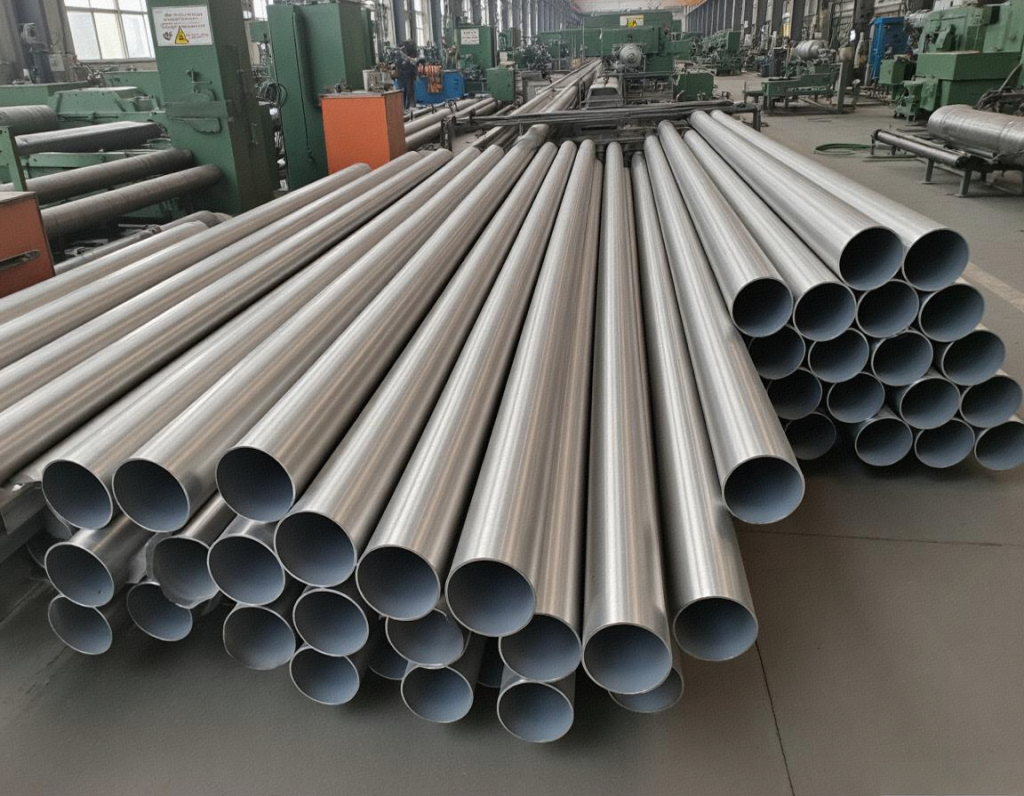

Precision-Crafted Metal Conduits for Demanding Environments

Engineered to withstand extreme pressures, these seamless cylindrical components combine ASTM-certified 300 series alloys with ±0.1% to 0.3% dimensional precision. The cold-rolled sch 80 stainless steel pipe variants feature 120-mesh polished surfaces, ideal for pharmaceutical piping systems requiring microbial resistance. A proprietary annealing process enhances stress corrosion cracking resistance across diameters spanning 1-100mm.

| Parameter | Specification |

|---|---|

| Lead Time | 7-day production cycle |

| Minimum Order | 1 metric ton |

| Primary Applications | Chemical reactor lining |

| Surface Hardness | 150-200 HV (Vickers scale) |

| Thermal Tolerance | -40°C to 850°C operational |

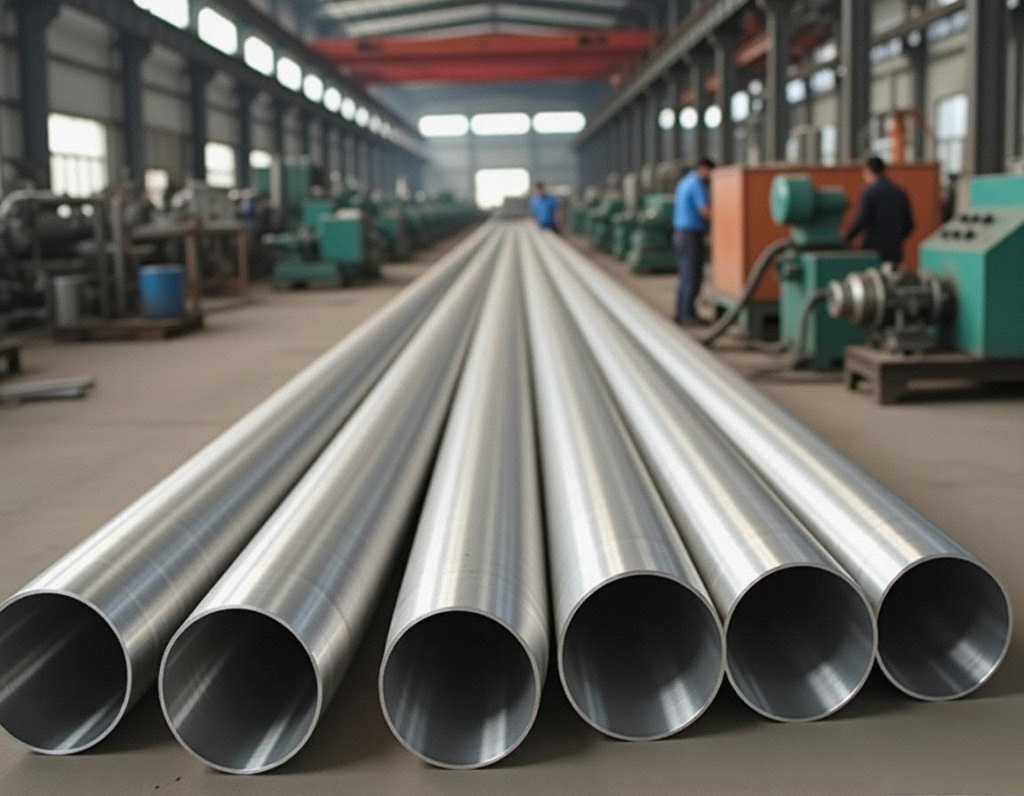

Optimized Flow Dynamics for Industrial Ecosystems

The electropolished interior of these conduits prevents particulate accumulation, making them compatible with stainless steel exhaust pipe cleaner solutions in automotive manufacturing systems. Seven specialized processing services—including CNC orbital welding and 3D laser cutting—enable customization for offshore oil rig cooling circuits or laboratory-grade fluid transfer networks.

Architectural-Grade Hydraulic Solutions

Incorporating duplex steel formulations, these tubes demonstrate 2.5x greater fatigue strength than conventional variants when deployed as stainless steel lily pipes in dialysis machines. The standardized seaworthy packaging ensures zero corrosion during transcontinental shipping, supported by flexible payment terms accommodating bulk procurement. Cold-drawn versions achieve 0.8μm Ra surface roughness for high-purity gas delivery in semiconductor fabs.