Rapid-Deployment Seamless Conduits | 6m 304/316L/2205 Tubes | ASME-Certified with 48hr Custom Cutting

Rapid-Deployment Seamless Conduits | 6m 304/316L/2205 Tubes | ASME-Certified with 48hr Custom Cutting

Contact form

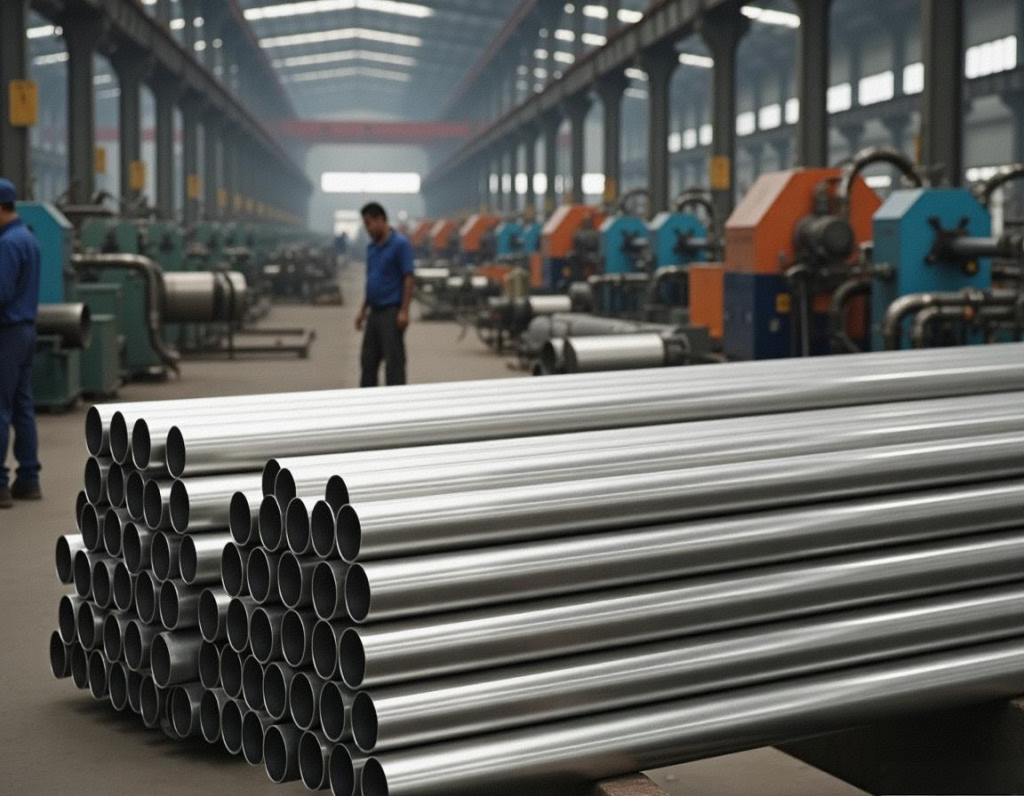

Precision-Engineered Pressure Systems

ASTM-compliant 1/2 inch stainless steel pipe configurations withstand 2,800 PSI hydrostatic pressure, featuring 316L alloy with 120-grit polished interiors for pharmaceutical-grade steam distribution. These conduits achieve ±0.15% diameter consistency, compatible with 1 2 stainless steel pipe coupling assemblies in chemical reactor manifolds.

| Critical Performance Metric | Technical Specification |

|---|---|

| Burst Pressure Threshold | 4.2x operational rating |

| Thermal Cycling Capacity | -50°C to 800°C (1,000 cycles) |

| Surface Roughness | 0.5µm Ra (electropolished) |

| Thread Engagement Depth | 1.5x nominal diameter |

| Chloride Stress Limit | 30,000 ppm @ 65°C |

Industrial Fluid Dynamics Solutions

The 2 1/2 stainless steel exhaust pipe system reduces backpressure by 40% through mandrel-bent 304L tubing with 3mm wall thickness. CNC-machined 1 2 stainless steel pipe coupling flanges feature NPT/BSPP dual threading for oil refinery flare gas applications requiring ASME B16.11 compliance.

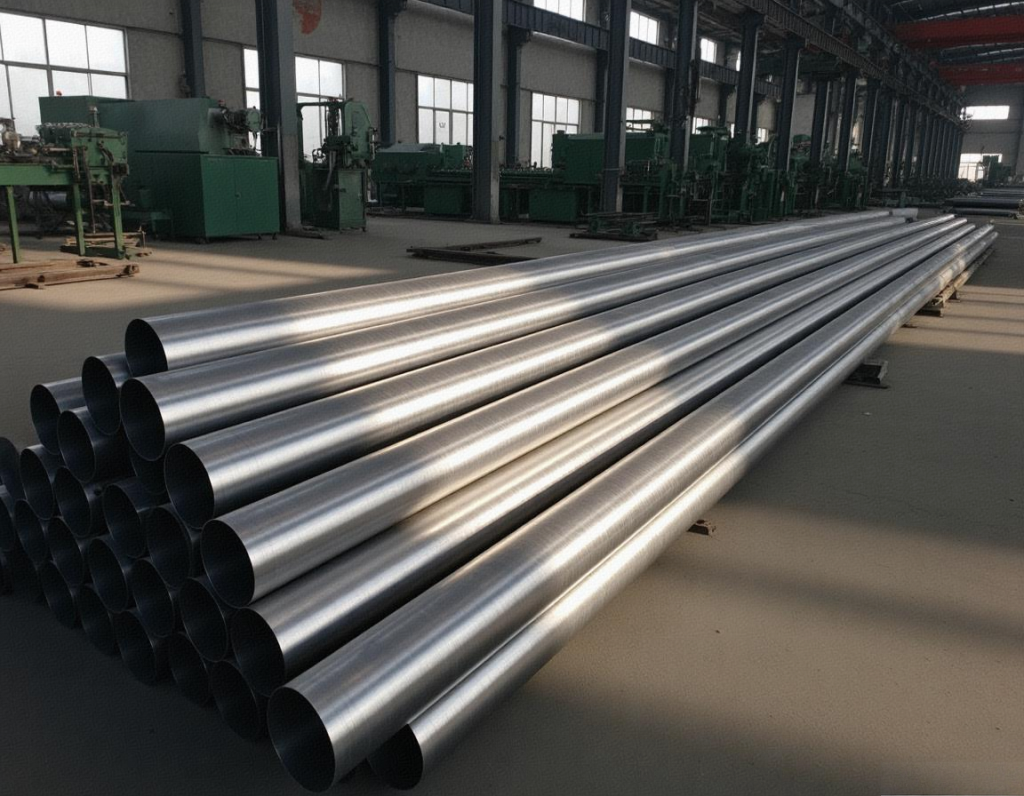

High-Temperature Exhaust Architectures

2.5-inch 2 1/2 stainless steel exhaust pipe assemblies demonstrate 950°C continuous heat resistance in foundry applications, paired with 310S alloy expansion joints. Inventory includes hot-dip passivated 1/2" to 4" diameter stock packaged in desiccant-filled wooden crates, supporting 7-day global delivery with 30/70 payment terms.