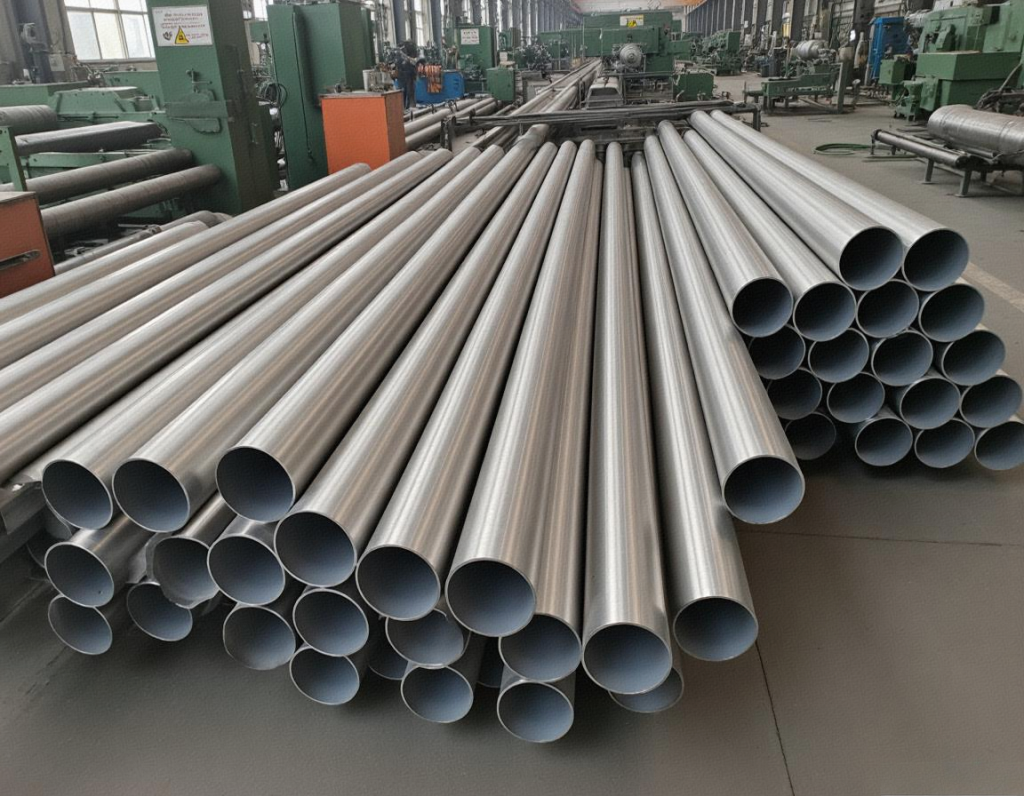

Precision-Engineered Stainless Conduits | 304/316L/2205 Welding Tubing Stock | ASME-Certified Thin-Wall Pipes with Custom Sizing

Precision-Engineered Stainless Conduits | 304/316L/2205 Welding Tubing Stock | ASME-Certified Thin-Wall Pipes with Custom Sizing

Contact form

Precision-Engineered Metal Conduits for Industrial Workflows

ASTM-compliant stainless steel pipe 304 variants achieve ±0.1% dimensional accuracy across 1-100mm diameters, with 2B finish enhancing corrosion resistance in chemical processing systems. Cold-rolled 300-series alloys including 316L and 2205 undergo stress-relief annealing, ideal for integrating with stainless steel pipe caps in high-pressure valve assemblies.

| Specification | Detail |

|---|---|

| Cyclic Salt Spray Test | 1,200+ hours resistance |

| Maximum Pressure Rating | 58 MPa (8,400 PSI) |

| Thermal Conductivity | 15 W/m·K at 100°C |

| Surface Roughness | 0.8μm Ra (mirror finish) |

| Thread Compatibility | NPT/BSPP/BSPT standards |

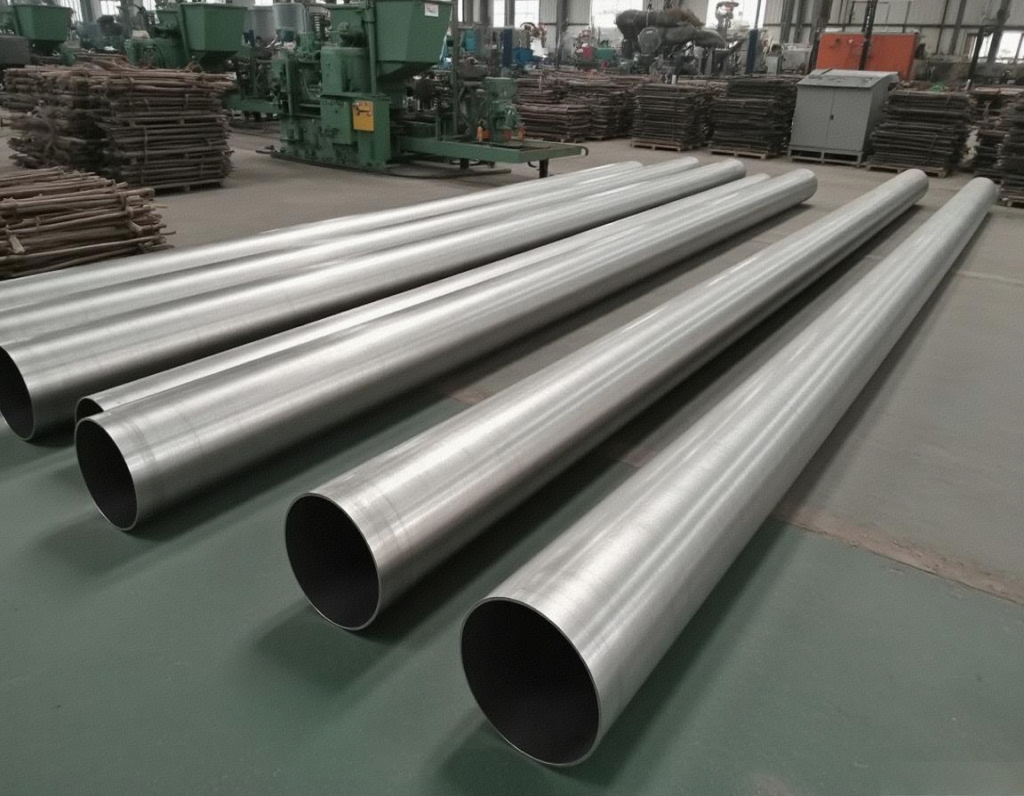

Optimized Fabrication Solutions for Critical Infrastructure

The stainless steel pipe cost-efficient inventory supports just-in-time delivery for construction frameworks requiring ASME B36.19 compliance. Seven specialized services—laser cutting, CNC bending, and TIG welding—enable customization of medical-grade tubing networks. Electropolished interiors prevent biofilm formation in pharmaceutical fluid transfer systems.

Durable Maritime-Grade Distribution Networks

Hot-rolled duplex steel variants demonstrate 2.3x greater pitting resistance than standard alloys when deployed with stainless steel pipe caps in offshore rigs. Wooden seaworthy crates with desiccant packs maintain zero-rust conditions during transcontinental shipping. Inventory includes SCH10-SCH160 profiles compatible with ANSI/ASME pressure vessel specifications, available in 1-ton batches with flexible payment terms.