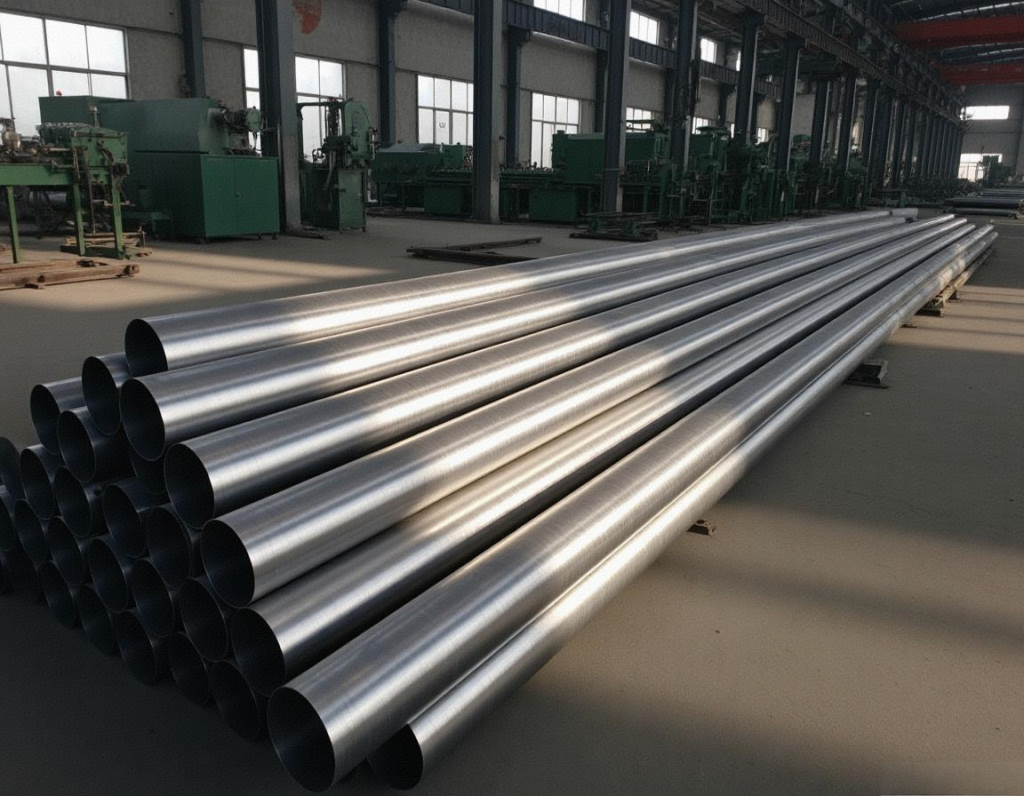

Precision-Engineered 2mm Wall Conduits | 304/316L/2205 Seamless Welding Tubing | ASME-Certified Corrosion Defense Systems

Precision-Engineered 2mm Wall Conduits | 304/316L/2205 Seamless Welding Tubing | ASME-Certified Corrosion Defense Systems

Contact form

High-Performance Fluid Transfer Solutions

ASTM-compliant 300-series stainless steel pipe couplers achieve ±0.1% concentricity tolerance, ideal for pressurized chemical transfer systems requiring 120-mesh polished surfaces. Cold-worked 316L variants demonstrate 1,500-hour salt spray resistance, compatible with stainless steel pipe plug accessories in pharmaceutical cleanrooms.

| Critical Performance Metric | Specification |

|---|---|

| Hydrostatic Pressure Test | 2.5x operational PSI rating |

| Intergranular Corrosion Test | Pass ASTM A262 Practice E |

| Maximum Temperature Threshold | 800°C (1,472°F) continuous |

| Dimensional Consistency | EN 10216-5 compliance |

| Surface Conductivity | <5 μΩ·cm electropolished |

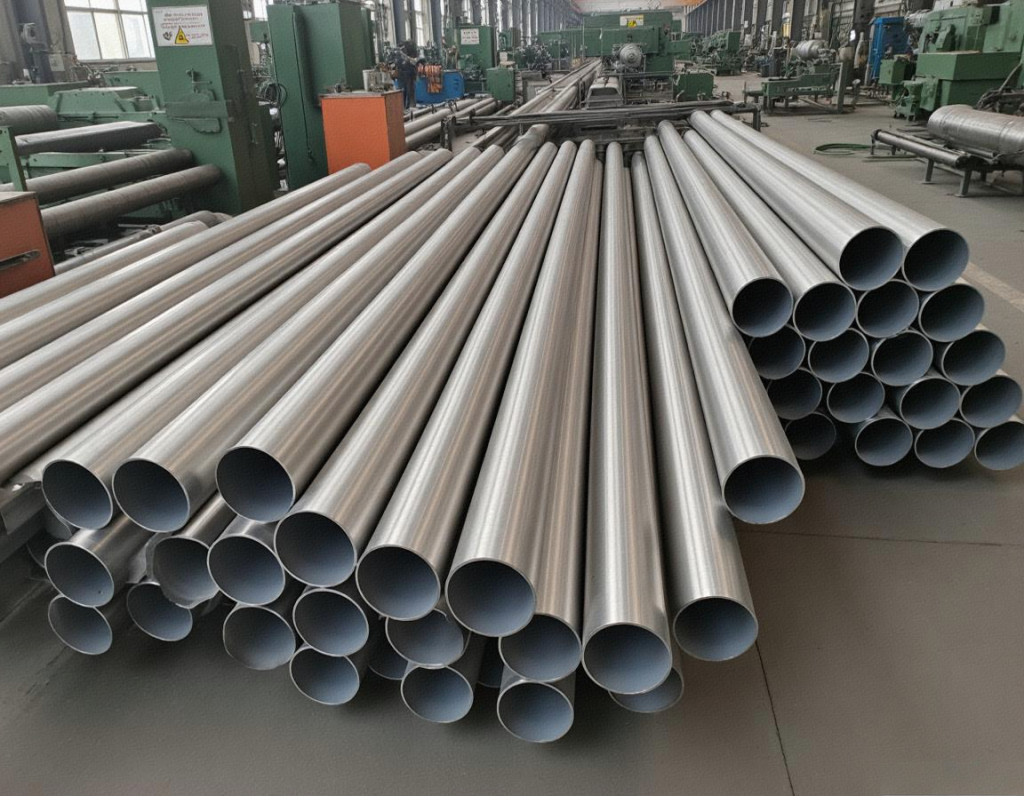

Certified Industrial Distribution Networks

Global stainless steel pipe fittings suppliers leverage CNC orbital welding and 3D laser cutting to customize SCH10-SCH160 conduits for offshore oil rigs. Seven-day turnaround services support just-in-time delivery of duplex 2205 pipes with NACE MR0175 sour gas compatibility.

Seamless Integration for Complex Architectures

Modular stainless steel pipe plug systems enable rapid deployment in structural frameworks requiring ASME B31.3 compliance. Hot-dip passivated surfaces prevent galvanic corrosion when paired with copper-nickel alloys. Inventory includes 1-100mm diameter stock with 30/70 payment terms, packaged in anti-static wooden crates for transoceanic shipments.