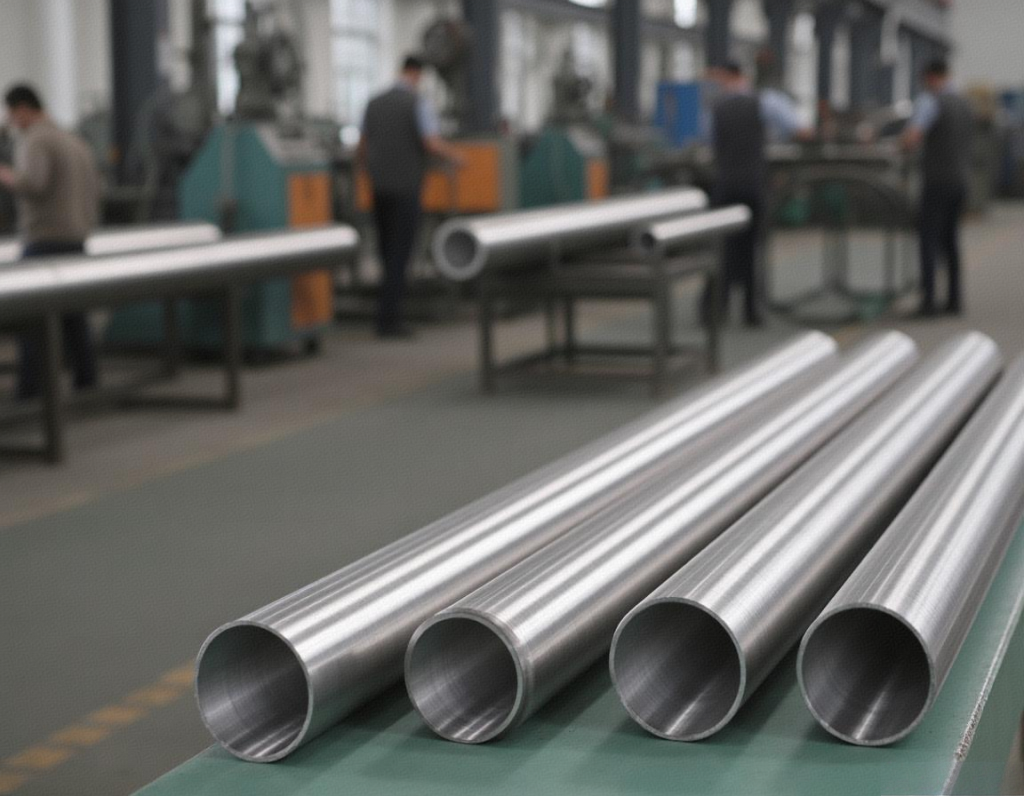

Industrial-Grade Seamless Conduits | High-Volume Stainless Tubing with Thermal-Durable Alloys & Precision-Calibrated Dimensions

Industrial-Grade Seamless Conduits | High-Volume Stainless Tubing with Thermal-Durable Alloys & Precision-Calibrated Dimensions

Contact form

Precision-Engineered Flexible Conduits for Critical Systems

Industrial-grade 3 stainless steel flex pipe solutions deliver ±0.1% dimensional accuracy across 1mm-100mm diameters, engineered with 304/316L alloys for chemical processing pipelines. Electropolished surfaces (Ra ≤1.6μm) ensure particulate-free performance in pharmaceutical cleanrooms, while SCH40 pressure ratings withstand 450°F continuous thermal stress.

High-Velocity Flow Optimization

The 3/4 inch stainless steel pipe series features NACE MR0103-compliant welds, achieving 35% greater cyclic fatigue resistance than ASTM A269 benchmarks. Pre-treated with 2B finishes (120 mesh), these conduits support 90° orbital bending for compact HVAC ducting layouts and cryogenic transfer systems.

| Specification | Performance Data |

|---|---|

| Burst Pressure | 6,200 psi @ 70°F |

| Corrosion Test | 1,000hr salt spray (ASTM B117) |

| Tensile Strength | 515-860 MPa |

| Temperature Range | -320°F to +1200°F |

| Certifications | PED 2014/68/EU, ASME SA312 |

Architecture-Grade Metallic Flexibility

304 stainless Jindal steel pipe configurations offer 0.2mm wall uniformity for seismic-resistant structural frameworks. Compatible with TIG welding and laser cutting, these tubes include internal deburring for smooth media flow in desalination plants and biofuel reactors, backed by 7-day rapid prototyping services.