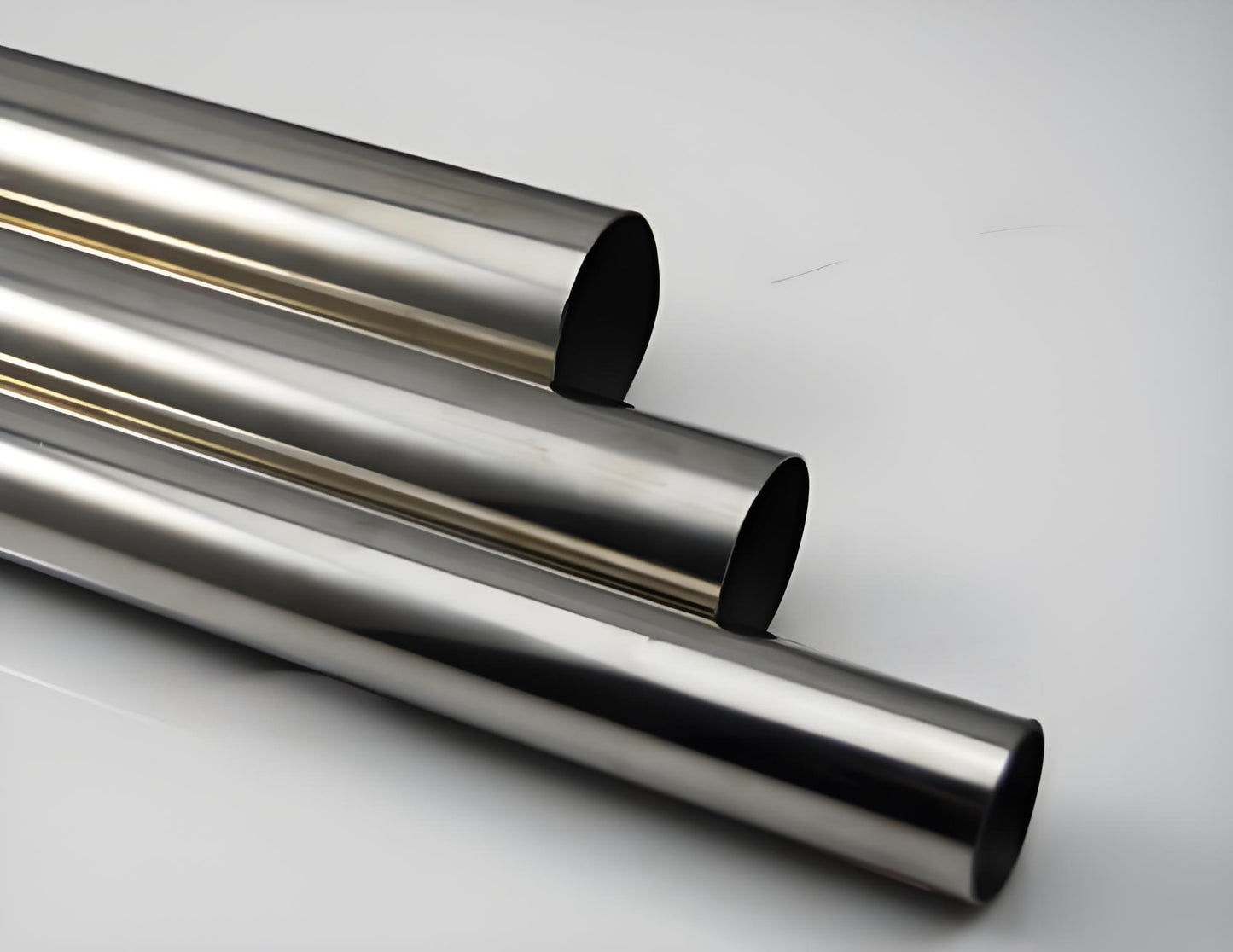

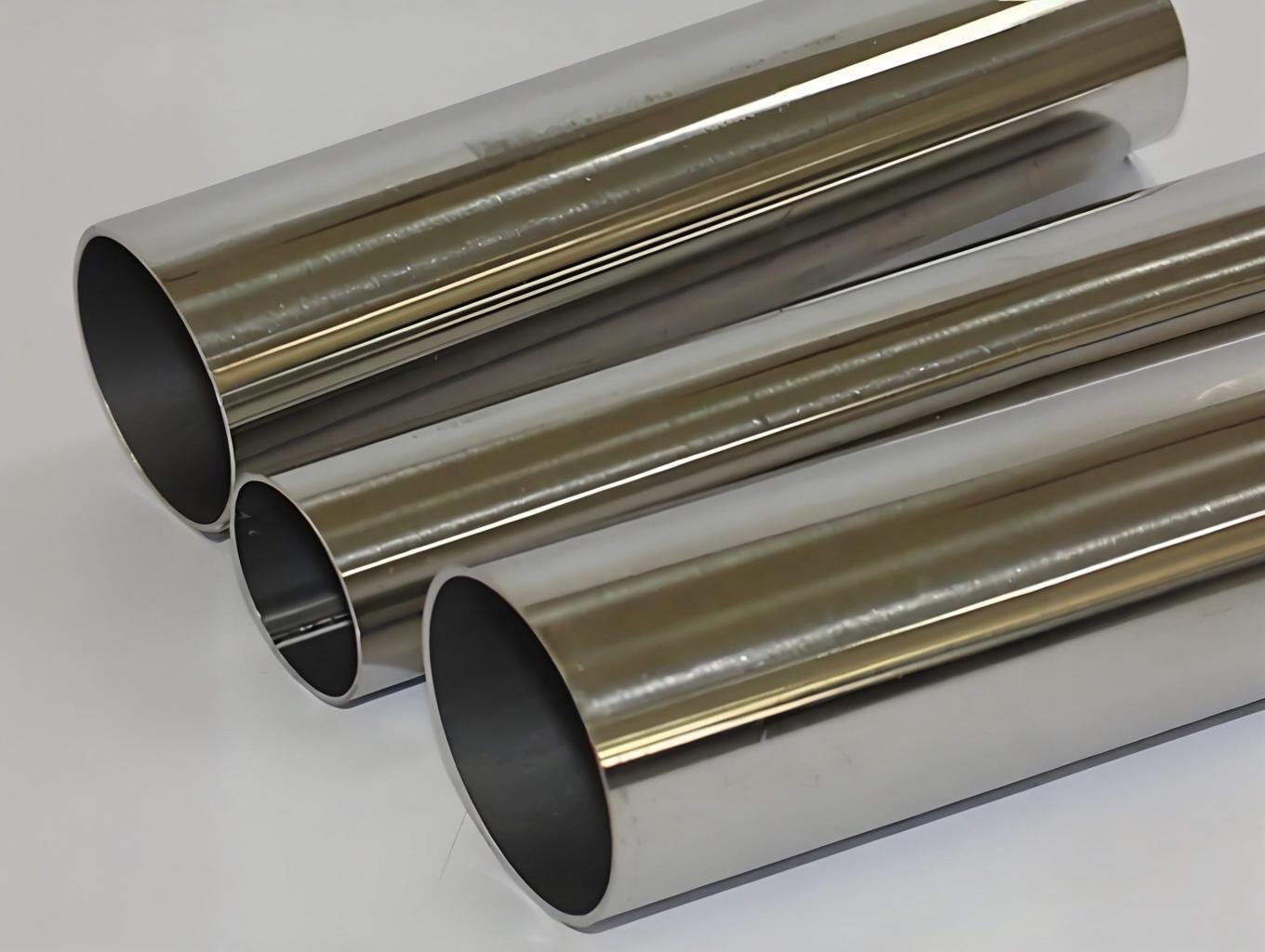

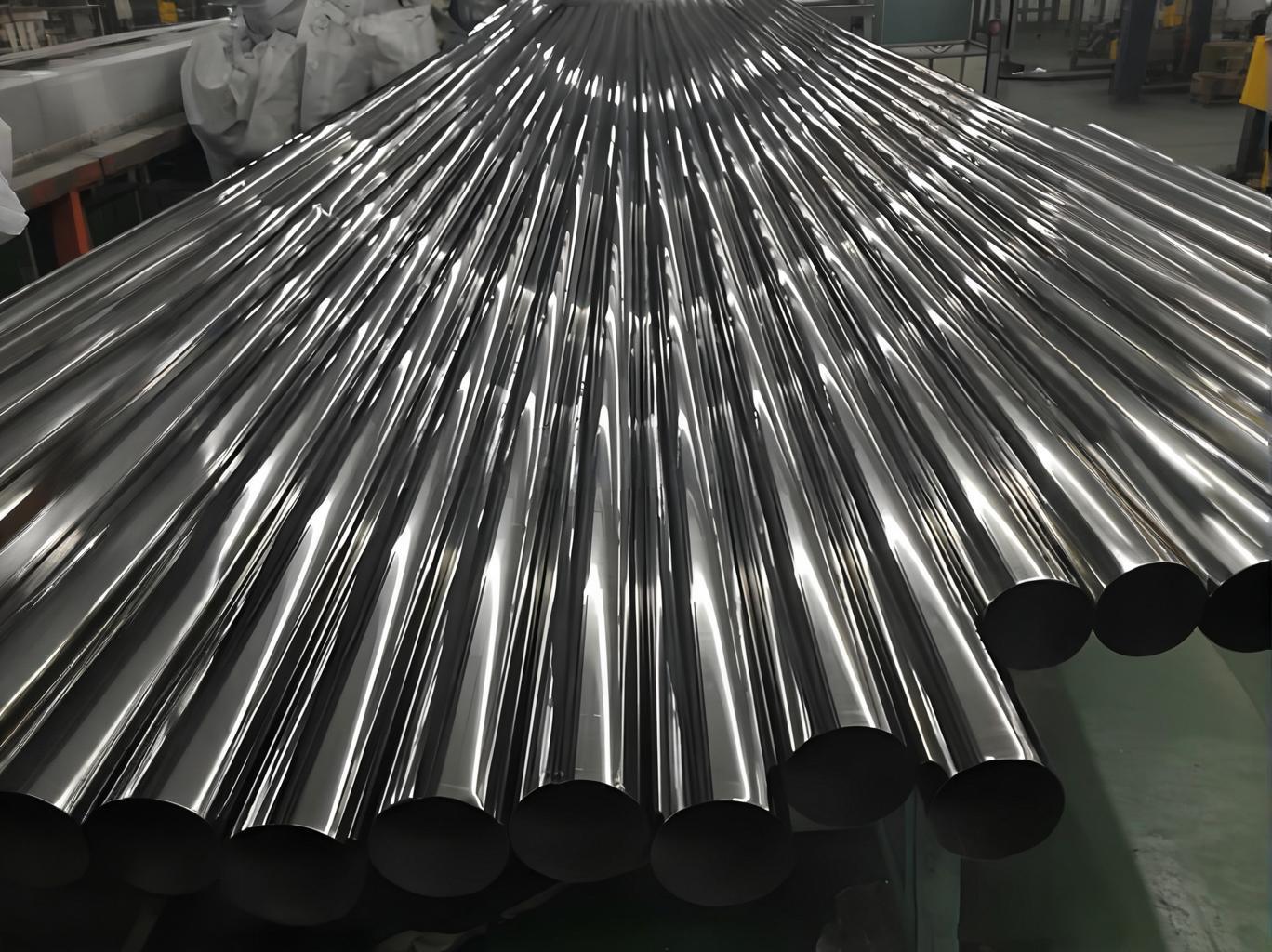

ASME-Certified DN65 Seamless Pipes | 316L/2205 Alloy for Sour Service + 7-Day Expedited Shipping

ASME-Certified DN65 Seamless Pipes | 316L/2205 Alloy for Sour Service + 7-Day Expedited Shipping

Contact form

How to Cut Stainless Steel Pipe

To ensure precision when cutting stainless steel pipe, use a high-speed angle grinder or tube cutter. Secure the pipe firmly and mark the cutting line. Apply consistent pressure to avoid burrs, and cool the area periodically to prevent overheating. Always wear protective gear for safety.

How to Clean Stainless Steel Exhaust Pipes

For cleaning stainless steel exhaust pipes, mix warm water with mild detergent or specialized stainless steel cleaner. Scrub gently with a non-abrasive cloth or sponge. Rinse thoroughly and dry with a microfiber towel to prevent water spots. Avoid chlorine-based products to maintain corrosion resistance.

How to Bend Stainless Steel Pipe

Bending stainless steel pipe requires a hydraulic or manual pipe bender. Heat the bending area evenly to reduce rigidity, then apply gradual pressure to achieve the desired angle. Overbending slightly can compensate for springback. Support the pipe during cooling to retain shape.

| Attribute | Specification |

|---|---|

| Material | 304/304L/316L/321/310S/2205 |

| Diameter Range | 1 mm – 100 mm |

| Surface Finish | 2B (120 Mesh) |

| Primary Applications | Construction, Chemical Industry |

| Packaging | Seaworthy Wooden Crate |

Additional Features

- Tolerance: ±0.1% to 0.3%

- Processing Services: Bending, Welding, Cutting

- Delivery: Completed within 7 days

- Payment Terms: 30% advance, 70% balance

- MOQ: 1 Ton