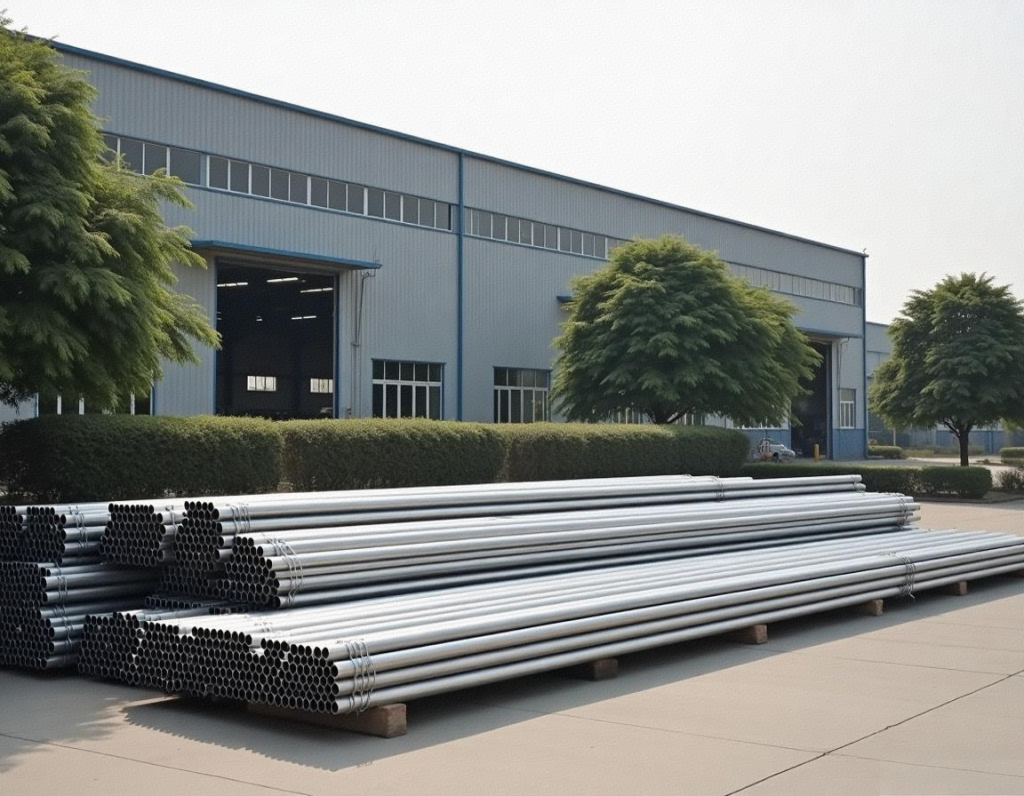

High-Strength Stainless Seamless Tubing | ASME-Certified 304/316L/2205 Alloys | Food-Grade Corrosion Resistant Pipes | Factory Direct Pricing & Rapid Cutting

High-Strength Stainless Seamless Tubing | ASME-Certified 304/316L/2205 Alloys | Food-Grade Corrosion Resistant Pipes | Factory Direct Pricing & Rapid Cutting

Contact form

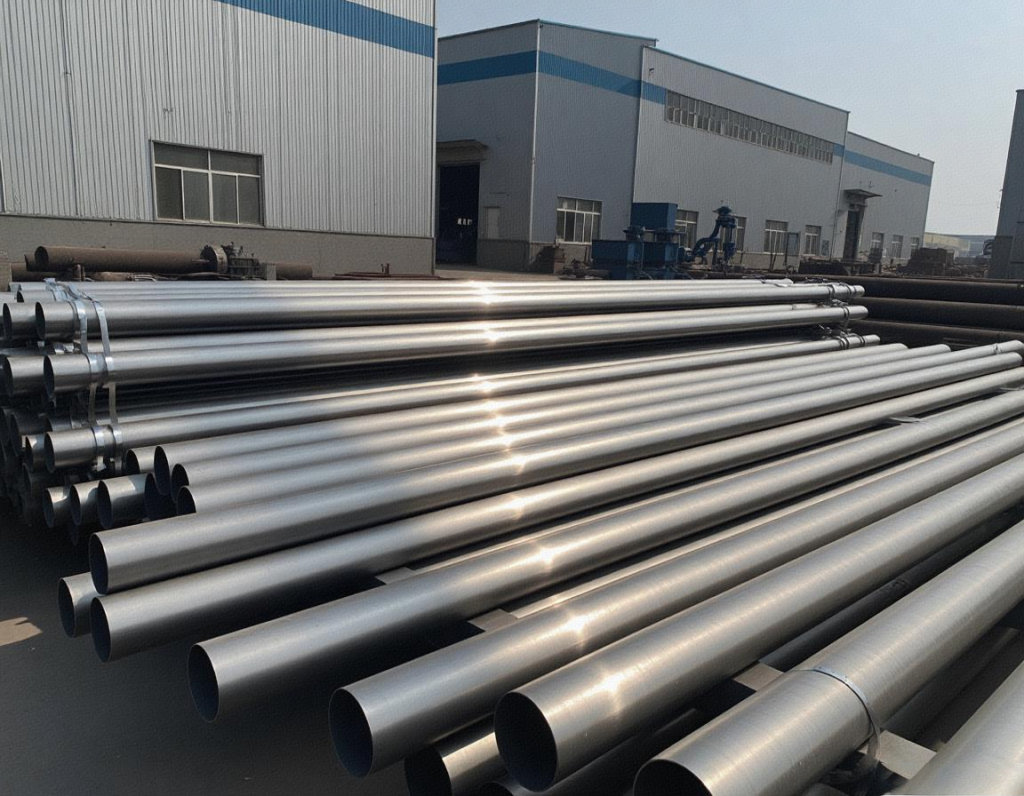

Precision-Forged High-Temperature Conduits

Engineered for extreme environments, our 310s stainless steel pipe excels in furnace systems with 1150°C oxidation resistance, featuring ASTM-compliant 2B finishes and ±0.1% dimensional accuracy. The 5 stainless steel pipe series offers 1mm-100mm diameters for structural frameworks, while 409 stainless steel exhaust pipe variants reduce automotive thermal fatigue through 12% chromium content.

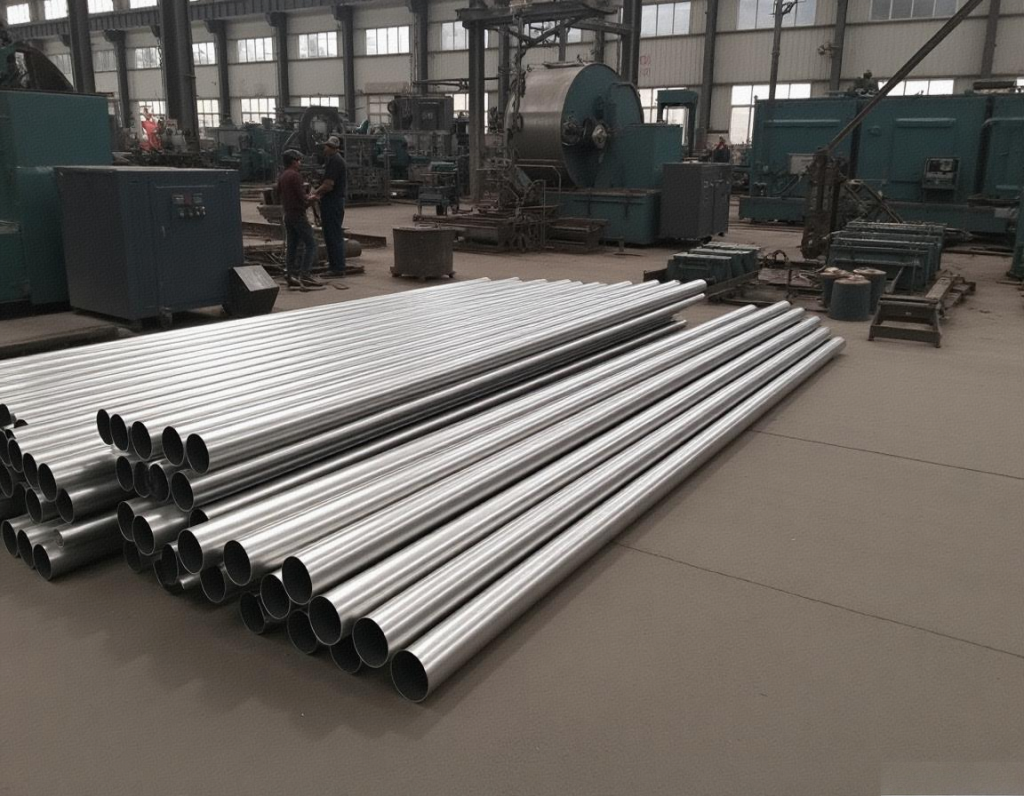

Multi-Industry Fluid Dynamics Mastery

Deploy corrosion-resistant tubing across:

- Petrochemical heat exchangers (310S)

- Vehicle exhaust manifolds (409)

- Pharmaceutical steam distribution (5-series)

Processing includes laser cutting for burr-free edges and CNC bending with 1.5D radius precision.

| Specification | Detail |

|---|---|

| Max Operating Pressure | 980 PSI (316L Grade) |

| Surface Hardness | HV 200-250 |

| Thermal Conductivity | 16.3 W/m·K (310S) |

| Intergranular Corrosion | Passed ASTM A262 Practice E |

| Straightness Tolerance | ≤1.5mm/m |

Certified Heavy-Duty Tubing Systems

From bold 409 stainless steel exhaust pipe assemblies in diesel engines to 310s alloy coils for pyrolysis reactors, our inventory supports rapid prototyping with 7-day lead times. All 5 stainless steel pipe shipments include 120 mesh polished surfaces, seaworthy wooden crates, and flexible MOQ terms for global logistics integration.