1

/

of

5

ASME SA213 Certified 304/316L/2205 Seamless Tubes | ±0.1% Tolerance for Power Plant Piping

ASME SA213 Certified 304/316L/2205 Seamless Tubes | ±0.1% Tolerance for Power Plant Piping

Contact form

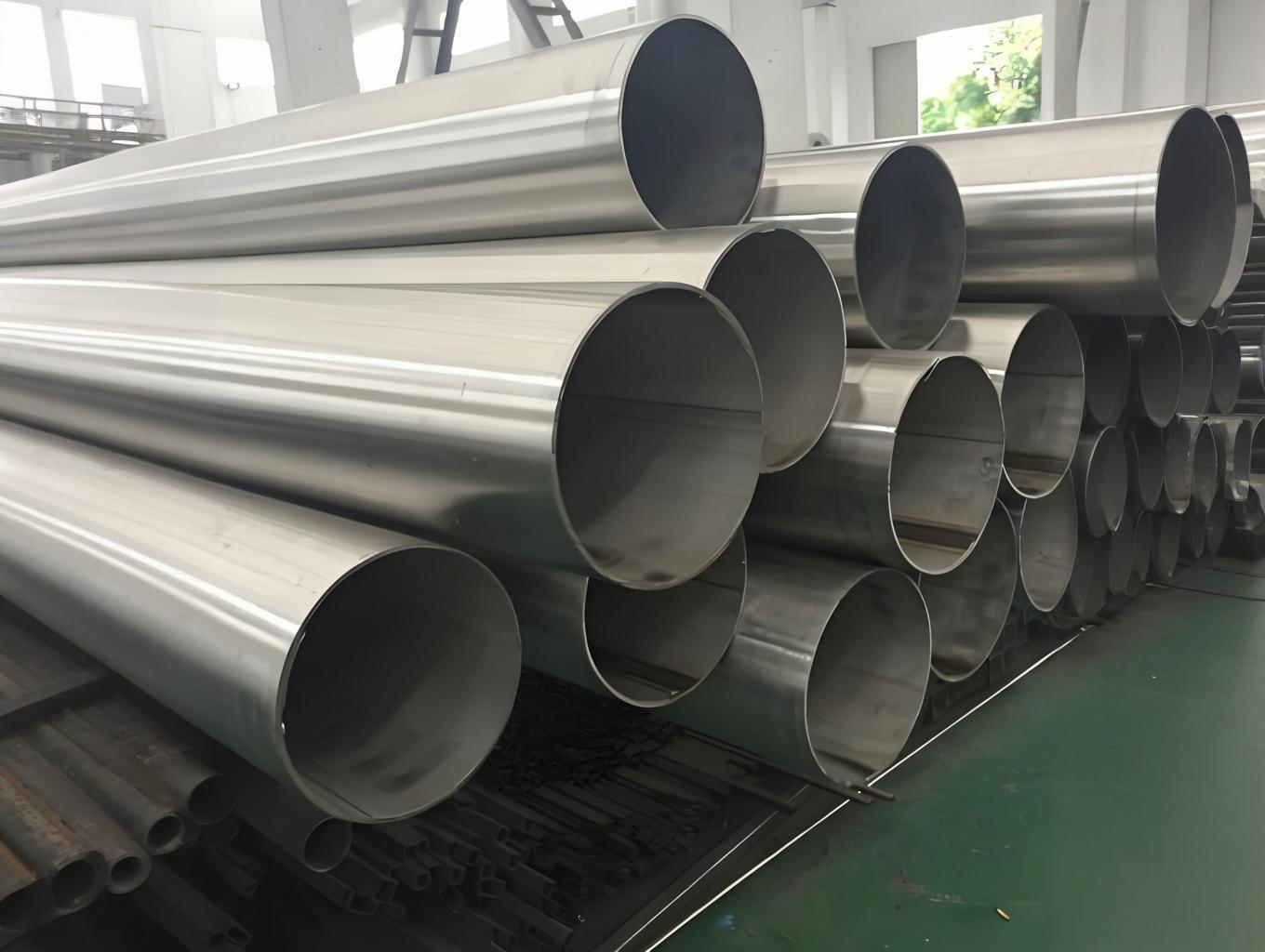

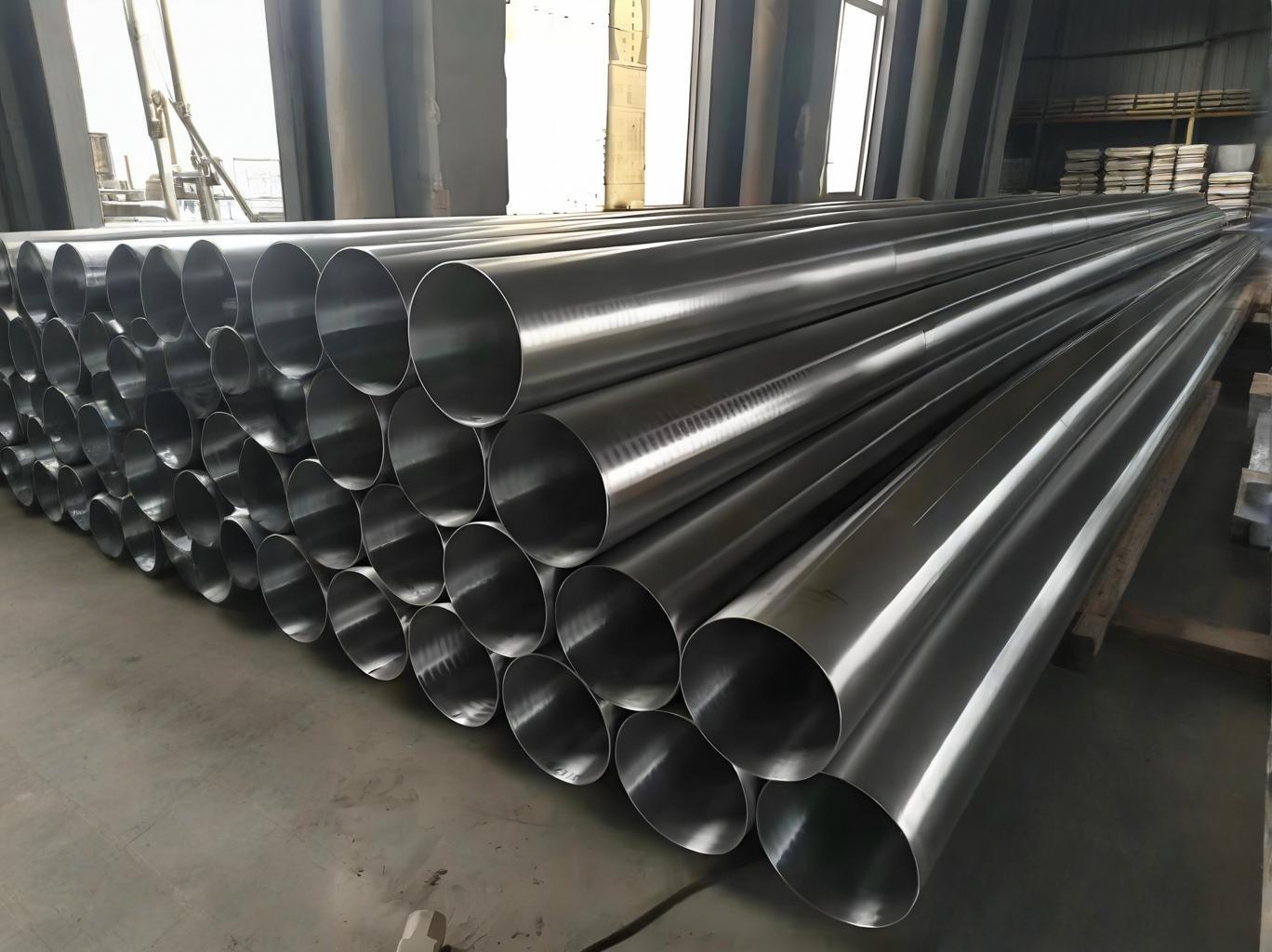

High-Performance Stainless Steel Seamless Tubing for Extreme Environments

ASME-Certified Precision Pipes with Multi-Industry Compliance

Technical Specifications:

- Material Grades: 301L, 304N, 316Ti, 316L, 321, 310S, 2205 duplex + 400 series alloys

- Dimensional Precision: ±0.1%-0.3% OD tolerance (1-100mm diameter range)

- Surface Finish: 2B cold-rolled with 120-grit electropolish (Ra ≤0.35μm)

- Compliance Standards: ASTM A269/A312, EN 10204 3.2, NACE MR0175

Critical Performance Advantages:

✓ Pitting Resistance (PREN 36+) for marine/chemical applications

✓ Rapid Production Cycle: 7-day manufacturing-to-shipment guarantee

✓ Custom Fabrication: CNC bending, orbital TIG welding, laser cutting

✓ Multi-Sector Applications: Nuclear containment systems, pharmaceutical bioreactors, offshore platforms

Enhanced Engineering Parameters:

- Temperature Range: -269°C (liquid helium) to 700°C cyclic operation

- Pressure Rating: SCH10S-SCH160S with 2.5x hydrostatic testing

- Yield Strength: 250-550 MPa (grade-dependent)

- Passivation Standard: ASTM A967 nitric acid method

Order Parameters:

- MOQ Flexibility: 1 metric ton batches with JIT delivery options

- Secure Transactions: LC/SBLC payment terms with escrow services

- Global Logistics: IPPC-certified crates (60×40×40cm; 1MT capacity)

Quality Assurance Protocol:

- Triple-stage inspection: PMI/XRF analysis, eddy current testing, helium leak detection

- Full DNV GL certification package with material traceability

- Salt spray testing exceeding 10,000 hours (ASTM B117)