1

/

of

5

ASME SA213 Certified 304/316L Tubes | Heat & Acid Resistant Pipes for Petrochemical Plants

ASME SA213 Certified 304/316L Tubes | Heat & Acid Resistant Pipes for Petrochemical Plants

Contact form

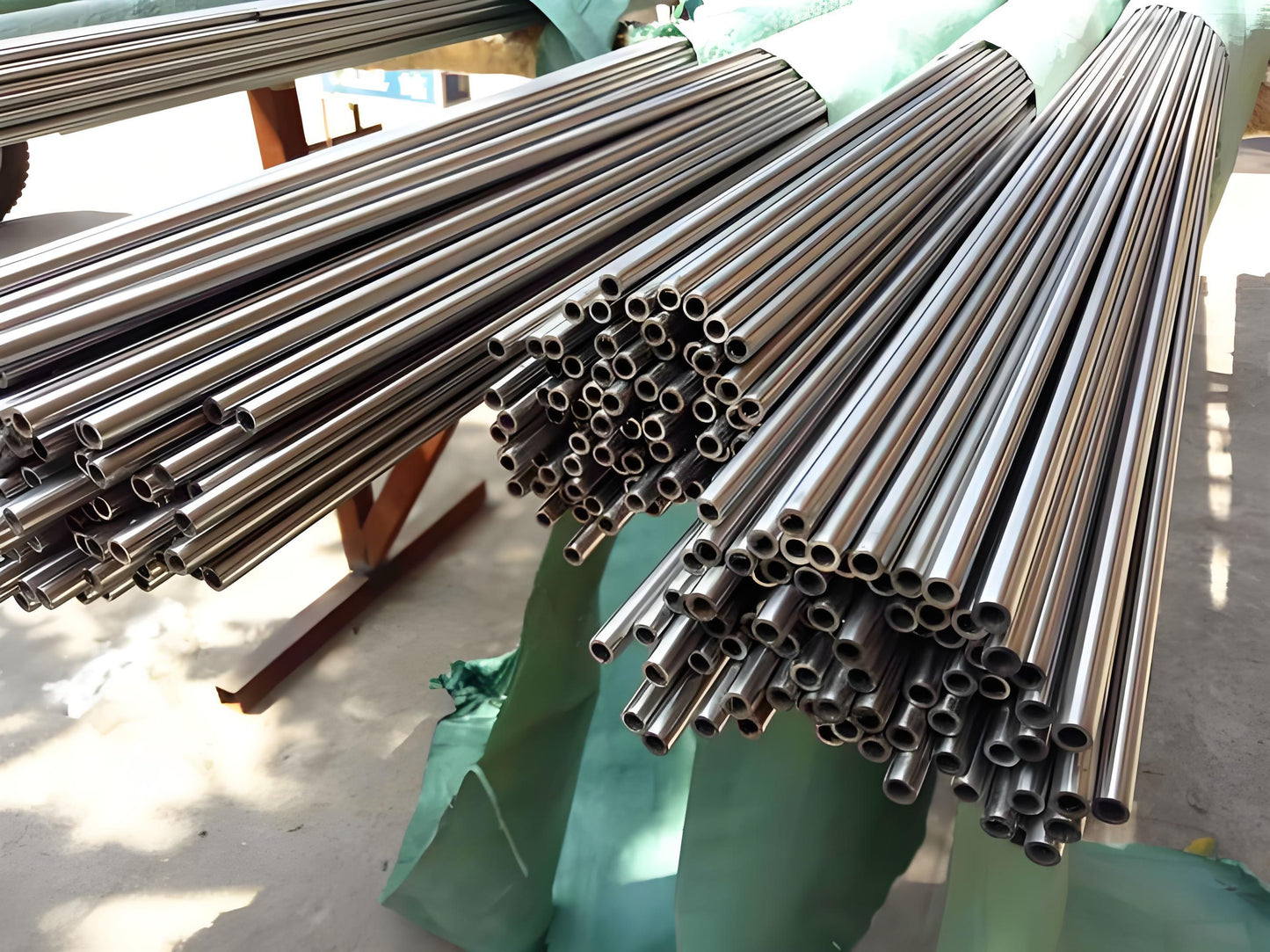

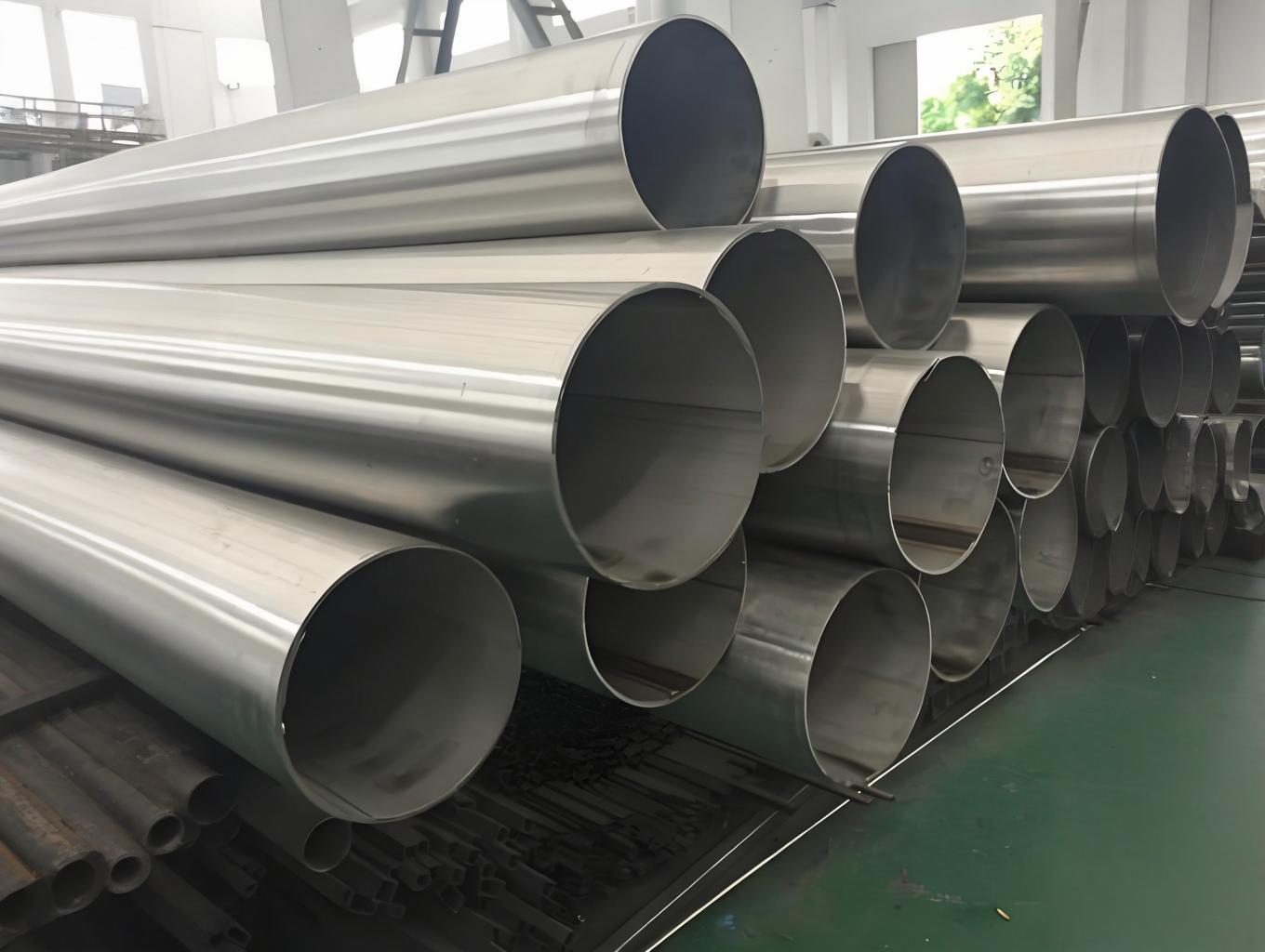

Precision Stainless Steel Seamless Tubing for Demanding Industrial Applications

ASTM-Certified Pipes with Multi-Industry Compliance & Enhanced Performance

Technical Specifications

- Material Grades: 301L, 304N, 316Ti, 316L, 321, 310S, 2205 duplex + 400 series alloys

- Dimensional Tolerance: ±0.1%-0.3% (1mm-100mm diameter range)

- Surface Finish: 2B cold-rolled with 120-grit electropolishing (Ra ≤0.35μm)

- Certifications: EN 10204 3.2, NACE MR0175, ASME BPE

Key Advantages

✓ Stress Corrosion Cracking Resistance

- Passes ASTM G48 Method D (25% NaCl at 45°C)

- PREN Values: 304(19.5) | 316L(28.3) | 2205(36.7)

✓ Extreme Temperature Performance

- Operational range: -196°C (cryogenic) to 700°C

- Hydrostatic tested at 2.5x working pressure

✓ Rapid Manufacturing

- 7-day end-to-end production cycle

- Full traceability from raw material to shipment

✓ Custom Fabrication Services

- CNC rotary draw bending (±0.5° accuracy)

- Orbital TIG welding for sanitary systems

Industry Applications

- Chemical Processing: Reactor liners, heat exchanger tubes

- Pharmaceutical: CIP/SIP systems, bioreactor piping

- Construction: Load-bearing structural components

- Energy: Nuclear coolant channels, LNG transfer lines

Order Parameters

| Category | Details |

|---|---|

| Minimum Order | 1 metric ton |

| Payment Terms | 30% advance TT + 70% balance |

| Packaging | IPPC-certified wooden crates |

| Dimensions | 60×40×40 cm (1,000kg capacity) |

Quality Assurance

- Material Verification

- PMI testing with XRF analyzers

- Eddy current defect detection

- Leak Testing

- Helium mass spectrometer (≤1×10⁻¹⁰ mbar·L/s)

- Durability Validation

- 10,000+ hour salt spray resistance (ASTM B117)

Why Choose Our Tubes?

- Medical-Grade Finish: Meets ASTM A270 sanitary standards

- Custom Passivation: Nitric acid or citric acid options

- Global Compliance: Documentation for PED/CE/ASME compliance