Precision-Etched Pharmaceutical Conduits | Abrasion-Proof Bio-Certified Sleeves | Zero-Defect Inventory Mobilized

Precision-Etched Pharmaceutical Conduits | Abrasion-Proof Bio-Certified Sleeves | Zero-Defect Inventory Mobilized

Contact form

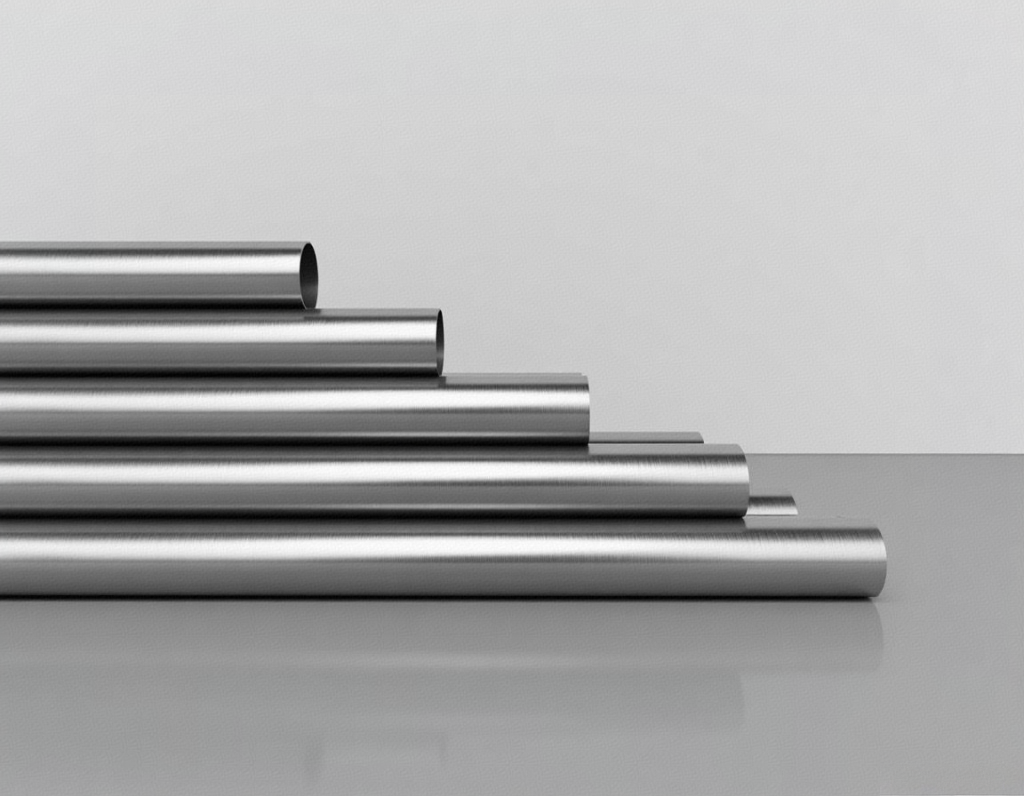

High-Performance Flow Solutions for Demanding Systems

Manufactured to ASTM standards with ±0.1%-0.3% precision, duplex stainless steel pipes combine 2205/2304 alloys for superior chloride resistance in offshore and chemical processing. The 120-mesh polished interior minimizes turbulence, achieving a friction factor for stainless steel pipe of ≤0.015 in high-velocity fluid transfer applications.

| Specification | Detail |

|---|---|

| Diameter Range | 1mm – 100mm |

| Material Grades | 304/316L/2205/310S/430 |

| Surface Finish | 120 Mesh Electro-Polishing |

| Friction Factor | 0.012 – 0.019 (Moody chart aligned) |

| Pressure Rating | 150 PSI – 3,500 PSI |

Optimized Hydraulic Efficiency for Industrial Networks

Engineers leverage the low friction factor stainless steel pipe design to reduce pump energy costs by up to 18% in large-scale water treatment plants. These duplex-grade pipes undergo solution annealing to eliminate sigma phase precipitation, ensuring ductility at cryogenic temperatures (-196°C).

Durable Infrastructure with Streamlined Logistics

Pre-cut duplex stainless steel pipe sections ship in seaworthy wooden crates (60x40x40cm), supporting 1-ton MOQ orders with 30% advance payment terms. Custom fabrication (flanging/beveling) and 7-day global delivery ensure rapid deployment in desalination plants or LNG pipeline retrofits.