Mill-Direct 304/316L/2205 Seamless Tubes | Massive Stock | ASME B36.19

Mill-Direct 304/316L/2205 Seamless Tubes | Massive Stock | ASME B36.19

Contact form

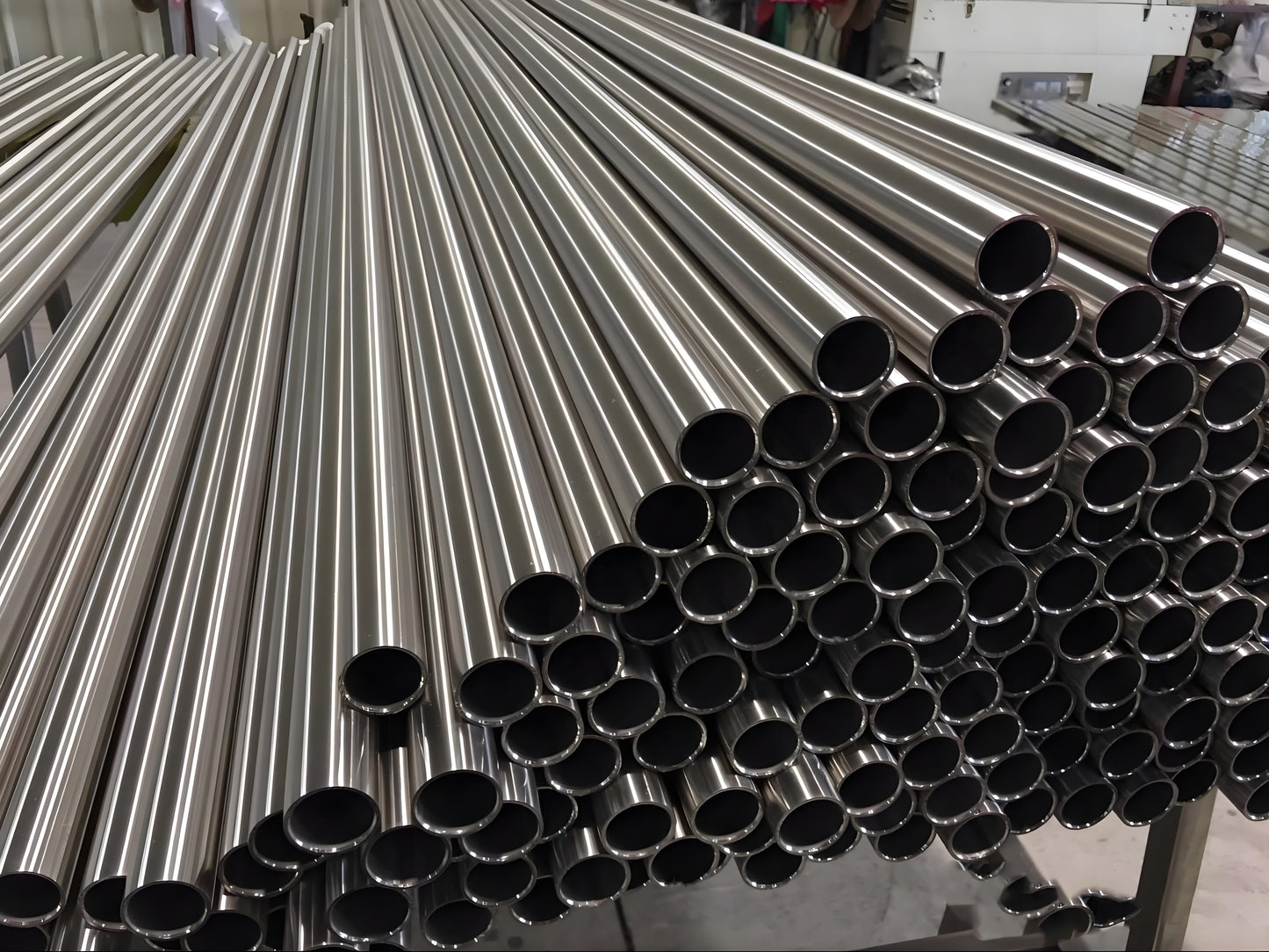

High-Precision Stainless Steel Tubing for Demanding Applications

Technical Specifications

Standard Compliance: ASTM

Material Grades: 300 Series (301L, 301, 304N, 304L, 310S, 316, 316L, 316Ti, 321, 410, 410S, 410L, 2205 Duplex)

Geometry: Round

Diameter Range: 1 mm to 100 mm

Dimensional Tolerance: ±0.1% to 0.3%

Surface Quality: 2B cold-rolled finish with 120-grit uniform polish

Performance Advantages

Extreme Corrosion Resistance: Engineered for chemical processing, coastal construction, and medical sterilization environments.

Multi-Process Compatibility: Supports precision cutting (laser/waterjet), CNC bending (3D/rotary draw), orbital welding, and flange punching.

Batch Traceability: Full metallurgical documentation including MTCs (Mill Test Certificates).

Industrial Applications

Chemical Plants: Acid-resistant transfer lines, heat exchanger cores

Medical Infrastructure: MRI component tubing, autoclave systems

Architectural Engineering: Seawall reinforcement rods, elevator guide rails

Customization & Services

Tailored Processing:

Decoiling to specific lengths (±1mm accuracy)

End finishing: bevelled, threaded, or grooved

Passivation treatment per ASTM A967

Protective Packaging: Triple-layer wooden crates with moisture barrier (60×40×40 cm unit dimensions, 1000 kg capacity).

Operational Efficiency

Rapid Turnaround: Production-to-shipment cycle ≤7 working days

Flexible Commerce:

MOQ: 1 metric ton

Tiered pricing for volume orders (20+ tons)

Secure payment: 30% deposit + 70% balance via TT

Quality Assurance Protocol

Ultrasonic testing for wall thickness uniformity

Eddy current inspection for surface defects

Hydrostatic pressure testing (optional to 6000 psi)