Ready-Stock Stainless Tubing | 1-500mm OD | Mirror & 2B Finishes

Ready-Stock Stainless Tubing | 1-500mm OD | Mirror & 2B Finishes

Contact form

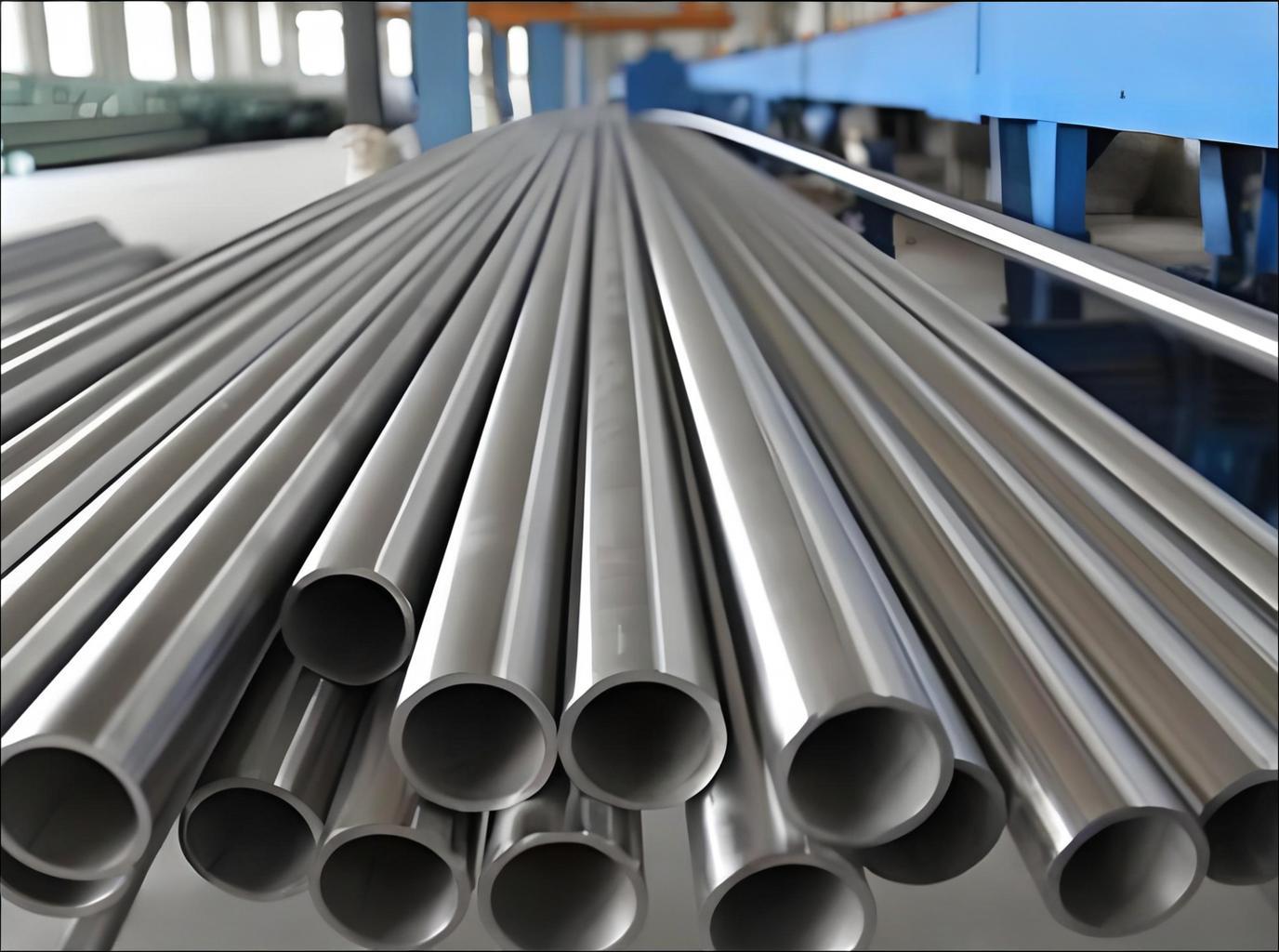

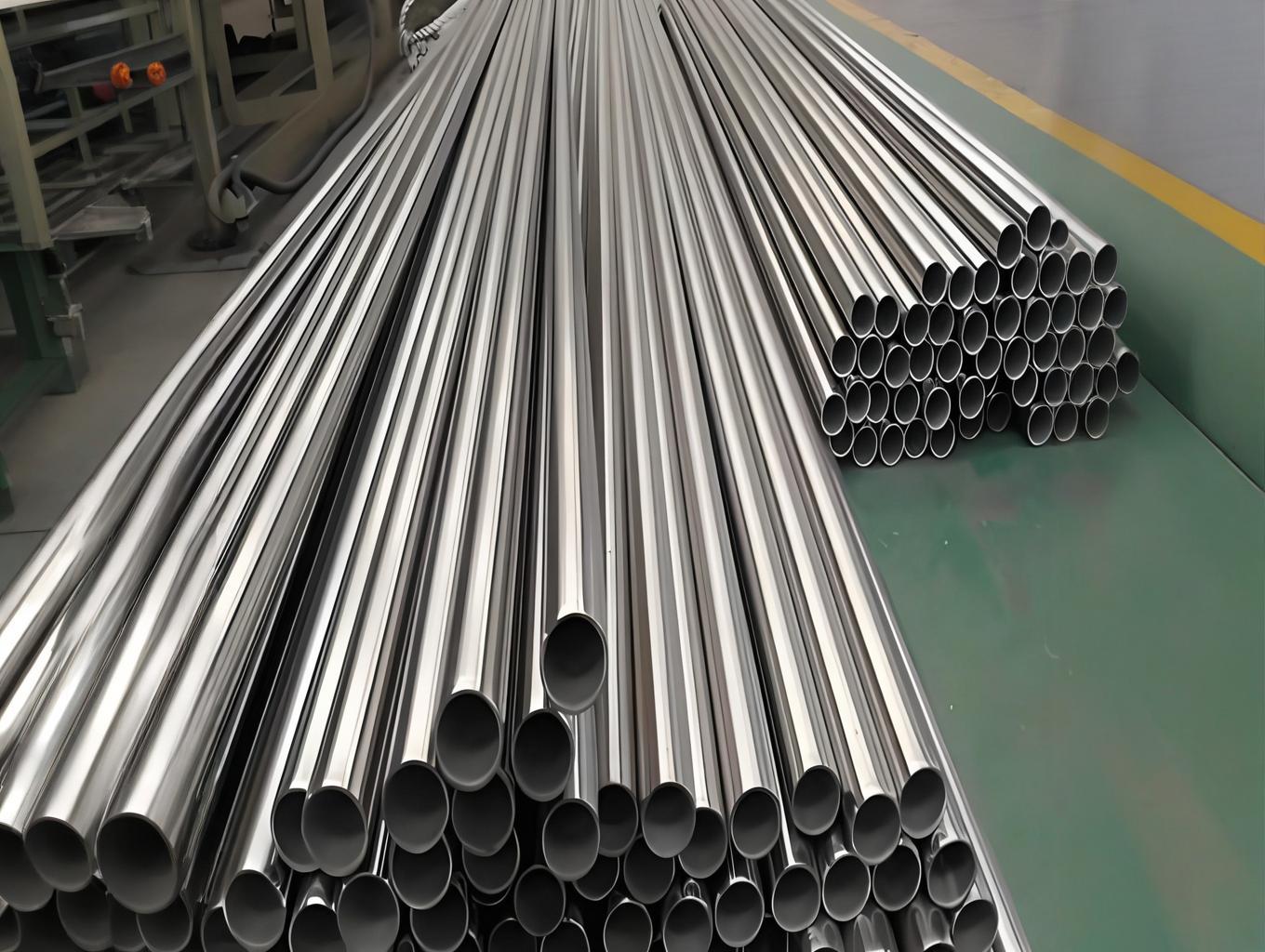

Precision Stainless Steel Tubes for Industrial Excellence

Technical Specifications

Standard Compliance: ASTM

Material Grades: 300 Series (301L, 301, 304N, 304L, 310S, 316, 316L, 316Ti, 321, 410, 410S, 410L, 2205 Duplex)

Geometry: Round

Diameter Range: 1 mm – 100 mm

Dimensional Tolerance: ±0.1% – 0.3%

Surface Finish: 2B cold-rolled with 120-grit uniform polish

Key Advantages

Extreme Durability: Exceptional corrosion resistance for harsh environments (chemical exposure, marine applications, medical sterilization).

Processing Versatility: Customizable via precision bending (±1° accuracy), TIG welding (argon-shielded), laser cutting (CNC-guided), and punching (up to 12mm thickness).

Batch Consistency: Full traceability with mill test certificates (MTCs) for chemical composition and mechanical properties.

Industrial Applications

Chemical Processing: Acid-resistant transfer lines, heat exchanger cores

Medical Infrastructure: Sterile fluid delivery systems, surgical instrument components

Structural Engineering: Seismic-resistant building frameworks, offshore platform supports

Packaging & Logistics

Secure Export Packaging: Triple-reinforced wooden crates with moisture-resistant lining (60×40×40 cm unit dimensions, 1000 kg gross weight).

Global Delivery: Guaranteed shipment within 7 working days via air/sea freight.

Flexible MOQ: Minimum order quantity of 1 metric ton, with bulk order discounts.

Quality Assurance

Dimensional Checks: Laser scanning for OD/wall thickness verification

Surface Inspection: Eddy current testing for micro-crack detection

Optional Certifications: NACE MR0175 (sour service), ISO 13485 (medical devices)

Value-Added Services

Technical Support: Free CAD/STEP files for system integration planning

Custom Finishing: Electropolishing (Ra <0.4μm) or pickling passivation upon request

Payment Terms: 30% advance TT + 70% balance with flexible LC options