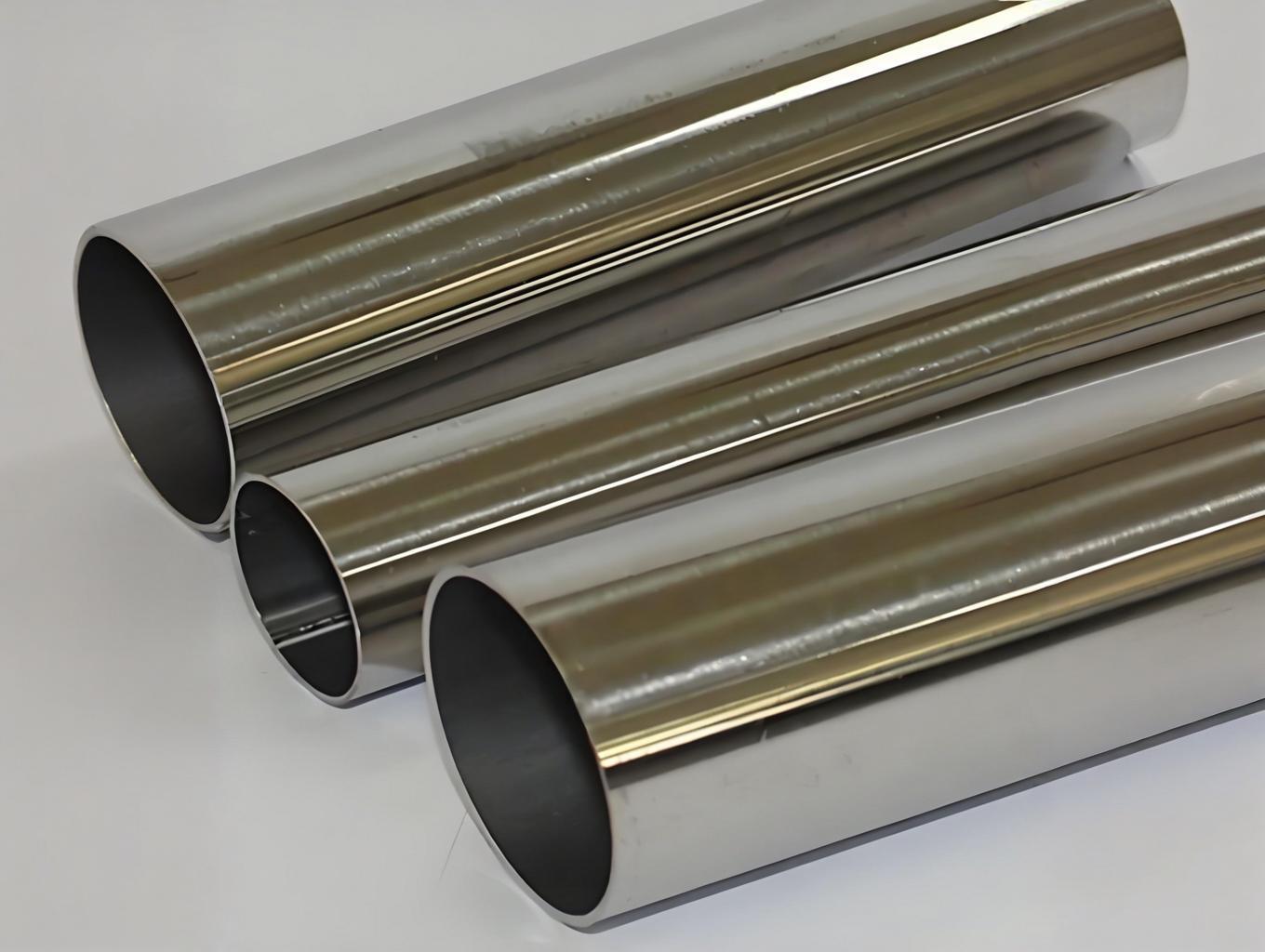

DN25 ASTM 304/316L/2205 Seamless Pipe | Corrosion-Resistant High-Temp Tubing + Custom Sizes

DN25 ASTM 304/316L/2205 Seamless Pipe | Corrosion-Resistant High-Temp Tubing + Custom Sizes

Contact form

Engineered Resilience for Demanding Fluid Systems

Harness the timeless reliability of stainless steel pipe ss 304 in environments where failure isn’t an option. From brewery CIP systems resisting lactic acid erosion to coastal HVAC ducts battling salt-laden winds, its 18% chromium armor thwarts pitting and crevice corrosion. For steam lines requiring airtight seals, pair with stainless steel pipe tape—PTFE-coated 316L variants endure 260°C temperatures while preventing galvanic corrosion between dissimilar metals. Whether extruding 6mm capillary tubes for chromatography or 100mm structural conduits for offshore platforms, ±0.1% dimensional tolerance ensures leak-free assemblies.

Precision Tooling for Flawless Installations

Transform raw tubing into mission-critical networks: Let stainless steel pipe threader systems carve perfect NPT or BSPP grooves into 410S-grade hydraulic lines, their carbide blades maintaining sharpness through 10,000 cycles. Thread-seal stainless steel pipe tape (0.075mm thickness) bridges microscopic imperfections in 304L biogas pipelines, while CNC mandrel benders contour 2205 duplex coils into seismic-resistant geothermal loops. For food-grade compliance, electropolish threaded 316L fittings to Ra ≤0.4μm, eliminating bacterial harbors. Even the most labyrinthine chemical plant layouts submit to modular stainless steel pipe ss 304 grids—plasma-cut, deburred, and ready for orbital welding.

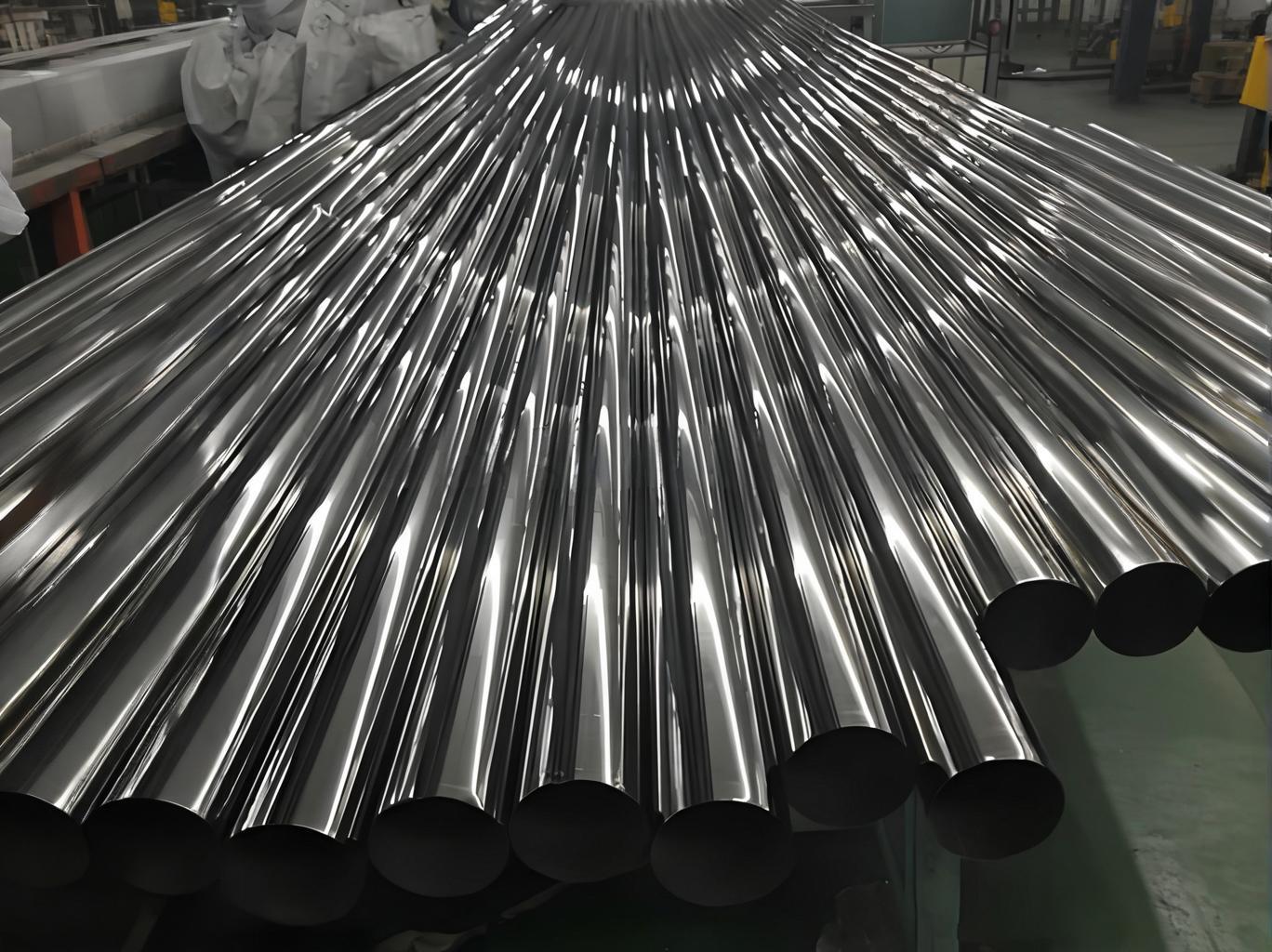

Global-Ready Logistics, Precision-Packed

Crates engineered for chaos: 60x40x40cm armored wood boxes cocoon 1-ton batches of threaded stainless steel pipe ss 304 fittings from monsoons to Arctic freezes. MOQ flexibility accommodates both microbreweries ordering 15mm diameter tubing and petrochemical giants sourcing DN200 schedule 80S pipes. With 7-day sprints from threading to dispatch, even emergency refinery retrofits stay on-schedule. Payment terms (30% TT advance) keep cashflow fluid; RFID-tagged stainless steel pipe threader toolkits ship with grind-certified mill reports. From pharmaceutical cleanrooms requiring passivated surfaces to oil rigs demanding sulfide-resistant 2205 alloys, every shipment arrives battle-tested and traceable—because global infrastructure waits for no one.